Argon introducing device and method for magnesium sponge titanium production

An introduction device and technology of sponge titanium, which is applied in the field of argon introduction device produced by magnesium sponge titanium, can solve the problems of poor product quality, inadequate cleaning of dust and other impurities, and achieve the effect of improving appearance and working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

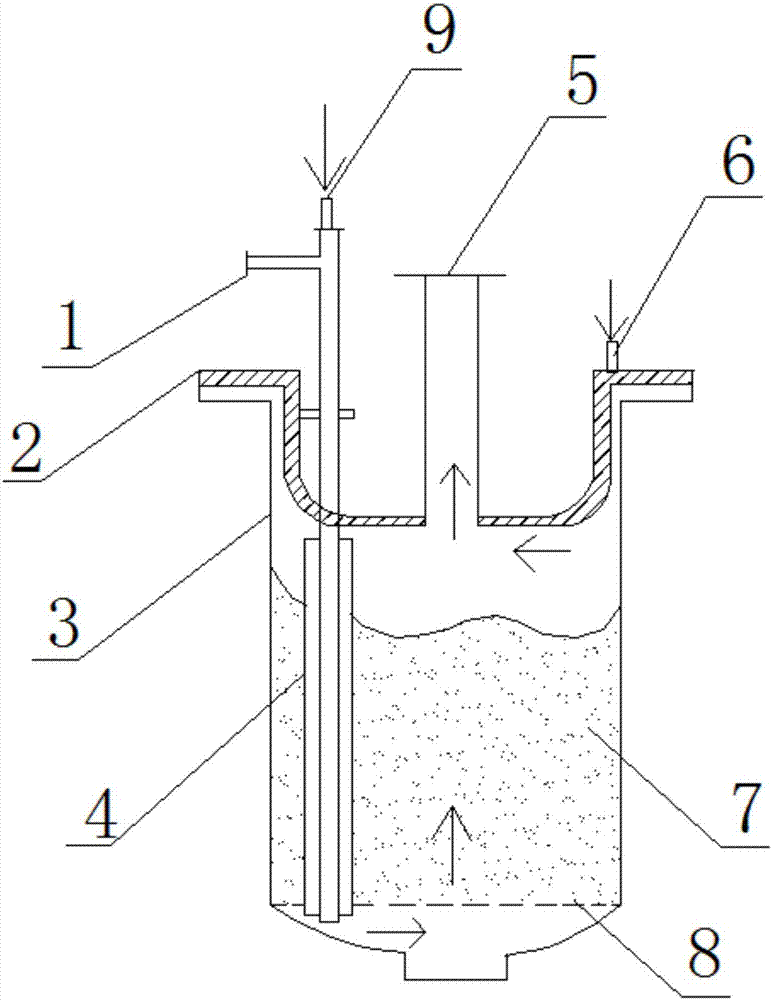

[0035] Such as figure 1 Shown, a kind of argon introducing device that is used for the production of magnesium sponge titanium, comprises reactor 3, reactor big cover 2, reduction product 7 is housed in reactor 3, and reactor big cover 2 is placed on reactor 3 top, A sieve plate 8 is provided at the bottom of the reactor 3, a magnesium chloride tube 1 with an end port lower than the sieve plate 8 is arranged on the reactor big cover 2, a channel 5 of the reactor big cover, and the magnesium chloride tube 1 is provided with a magnesium chloride tube argon filling port 9, One side of the large reactor cover is provided with an argon filling port 6 of the large reactor cover; the magnesium chloride tube 1 is provided with a magnesium chloride tube casing 4; one end port of the magnesium chloride tube casing 4 is at least 10 mm lower than the sieve plate 8; The sieve plate 8 is provided with a sieve hole, and the diameter of the sieve hole is 25-30cm; the large cover channel 5 of ...

Embodiment 2

[0037] Such as figure 1 As shown, a method for introducing argon gas for magnesium sponge titanium production, during transdistillation, argon gas enters the reactor 3 through the argon filling port 9 of the magnesium chloride tube, passes through the area below the sieve plate 8, reduces the product 7 and passes upward The large reactor cover channel 5 discharges a large amount of mixed gas flow containing argon, dust, low-valent chlorides, etc.

Embodiment 3

[0039] Such as figure 1 As shown, a method for introducing argon gas for the production of sponge titanium by magnesium method is to inject argon gas through the argon filling port 6 of the large reactor cover, and the argon gas enters the reactor 3, and the surface of the reduced product 7 is discharged from the reactor The large cover channel 5 discharges the mixed gas flow containing argon, dust, low-valent chloride, etc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com