Automatic regulation system and method for electrolyte

An automatic adjustment and electrolyte technology, which is applied in the field of electrolyte analysis, can solve problems such as inaccurate copper ion concentration, consume manpower and material resources, and affect work efficiency, so as to improve the accuracy of copper ions, reduce production costs, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

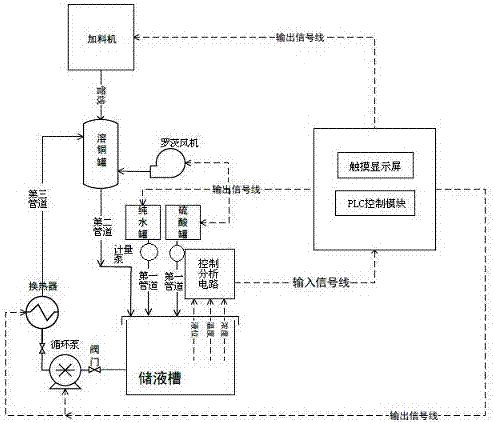

[0027] Such as figure 1 As shown, an electrolyte automatic adjustment system disclosed in the present invention includes a copper melting reaction system, a detection system and an adjustment system, in which:

[0028] The copper melting reaction system includes a liquid storage tank, a pure water tank, a sulfuric acid tank, a Roots blower, a copper melting tank, a feeder, a heat exchanger, a circulating pump and a valve, wherein the pure water tank and the sulfuric acid tank are connected through a first pipeline A liquid storage tank, and a metering pump is installed on the first pipeline, the feeder is connected to the copper melting tank, and copper rice is added to the copper melting tank, and the Roots blower is connected to the copper melting tank, and oxygen and copper rice are fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com