Method for evaluating near-well fractured crack through Gd neutron tracing yield imaging

A neutron and imaging technology, used in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve problems such as large influence, inability to accurately determine wellbore residues, and restrictions on the promotion of radioactive tracer proppants. High sensitivity, fracture identification visualization, accurate dip and azimuth identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

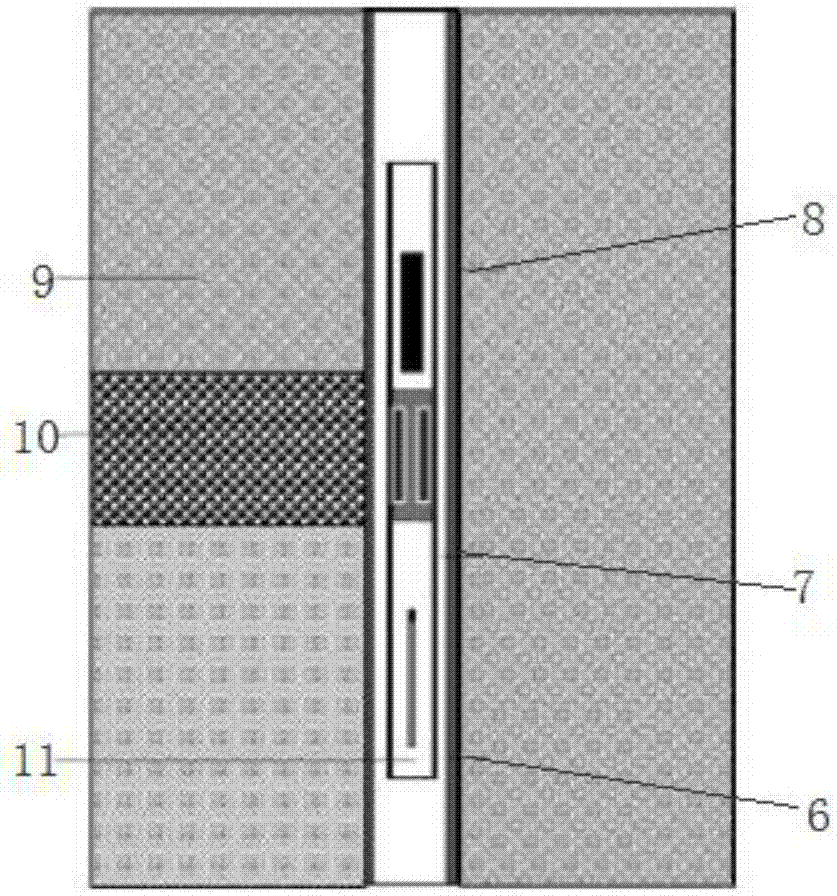

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

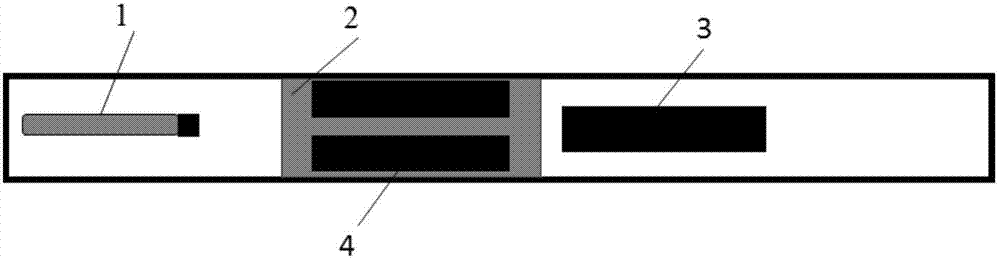

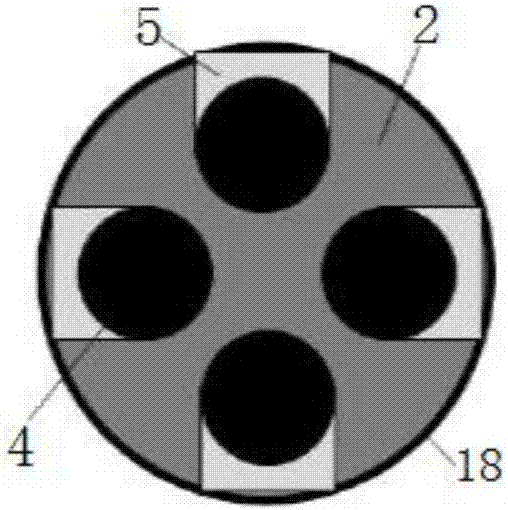

[0030] Such as Figure 1-Figure 2 As shown, a method of using Gd neutron tracer yield imaging to evaluate near-wellbore fracturing fractures, by adding high-capture cross-section materials to the proppant, using the interaction between neutrons and Gd in the proppant, through the array azimuth gamma instrument And neutron instruments, to obtain Gd production in different azimuths and borehole capture gamma, to perform fracture imaging, specifically including the following steps:

[0031] Step 1: After the formation is hydraulically fractured, a marked proppant containing Gd2O3 is injected into the fractured formation;

[0032] Step 2: Measure the capture gamma energy spectrum and thermal neutron time spectrum by using the array azimuth gamma instrument and neutron measuring instrument;

[0033] Step 3: Process the mixed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com