Energy storage electric cylinder

An electric cylinder and energy storage technology, applied in the field of mechanical transmission, can solve the problems of waste of ability to provide kinetic energy, waste of energy, not being used, etc., and achieve the effects of increasing work efficiency, reducing costs, and improving response speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

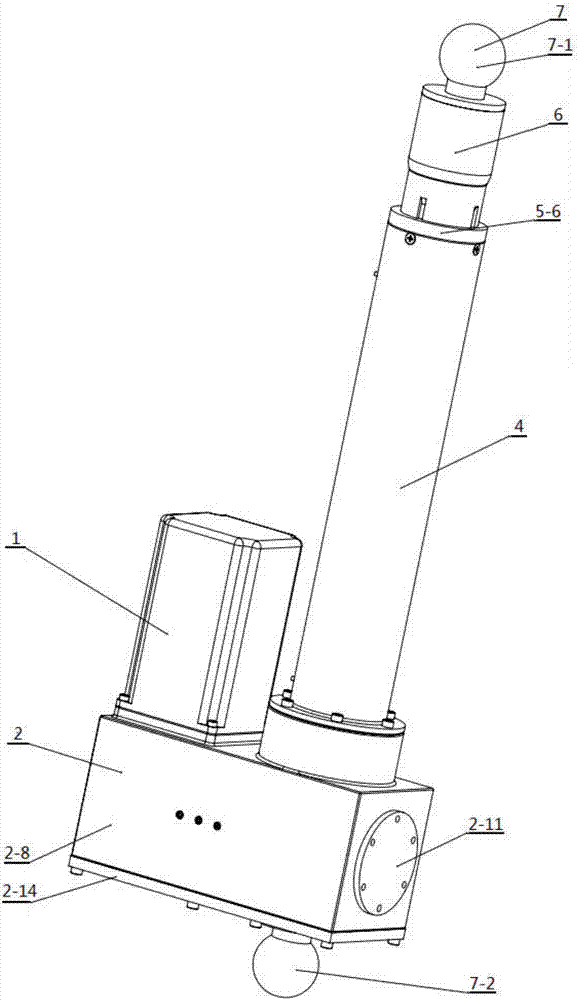

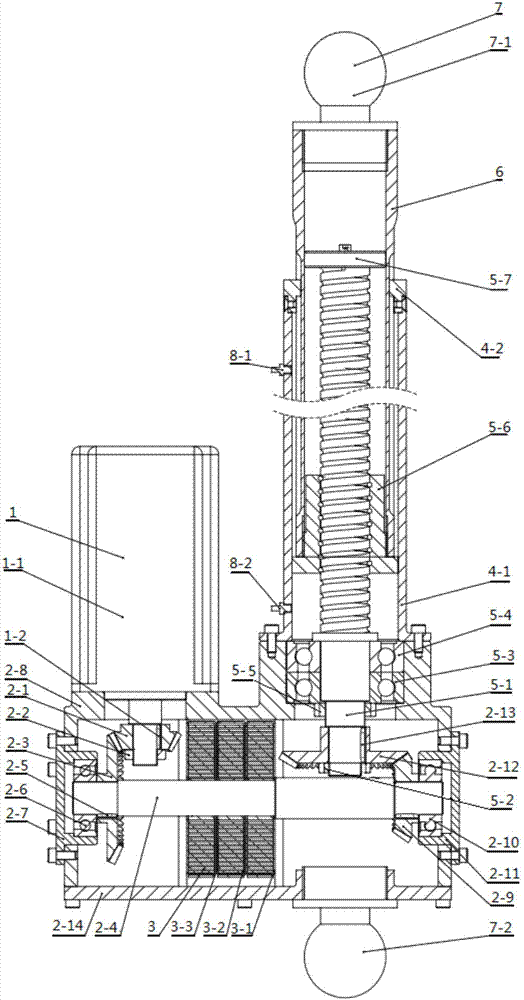

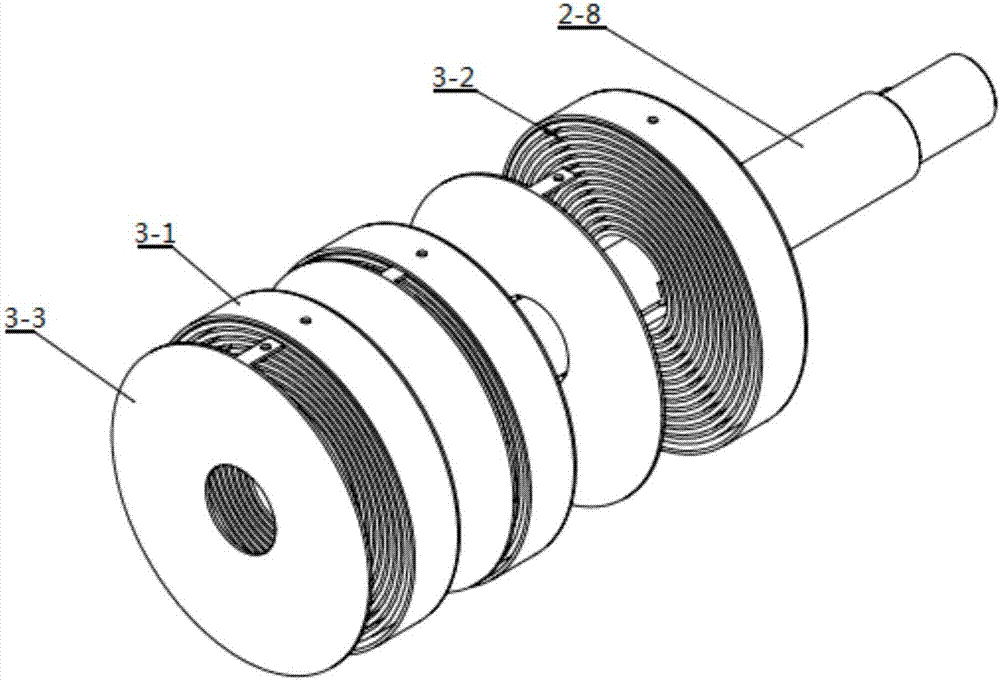

[0028] An energy storage electric cylinder is composed of a motor assembly (1), a reducer (2), a coil spring assembly (3), a cylinder assembly (4), a screw subassembly (5), a push rod (6), and an installation Component (7) and limit switch (8) are formed. It is characterized in that: the motor assembly (1) is installed on the upper end of the reducer (2) through screws, and the helical gear 1 (2-1) is installed on the output shaft of the motor (1-1), and the helical gear 1 (2-1) is installed on the output shaft of the motor (1-1). 1) Process the keyway on the shaft hole of the motor (1-1) and the output shaft of the motor (1-1), and restrict the helical gear 1 (2-1) and The output shaft of the motor (1-1) rotates relative to each other. The end of the output shaft of the motor (1-1) is processed with external threads, and the upper end surface of the helical gear 1 (2-1) is tightened by tightening the lock nut 1 (2-2). Close to the stepped surface on the output shaft of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com