Telescoping wheel type chassis

A telescopic wheel and chassis technology, applied in the direction of mobile frames, engine frames, supporting machines, etc., can solve the problems of poor mobility, low flexibility, and large frictional resistance of the chassis, and achieve compact vertical dimensions and wide construction range, motion smoothing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

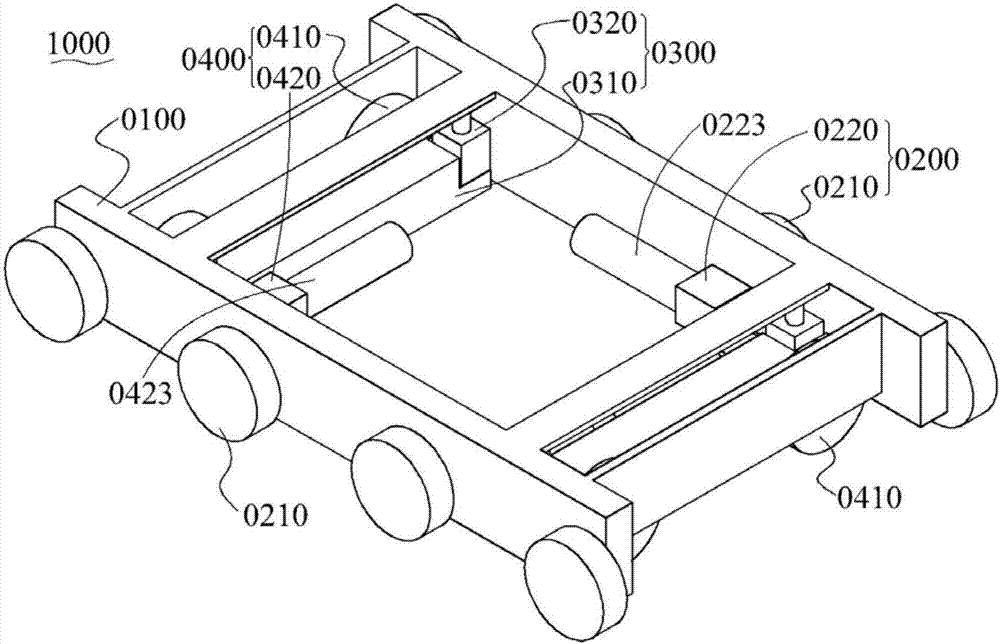

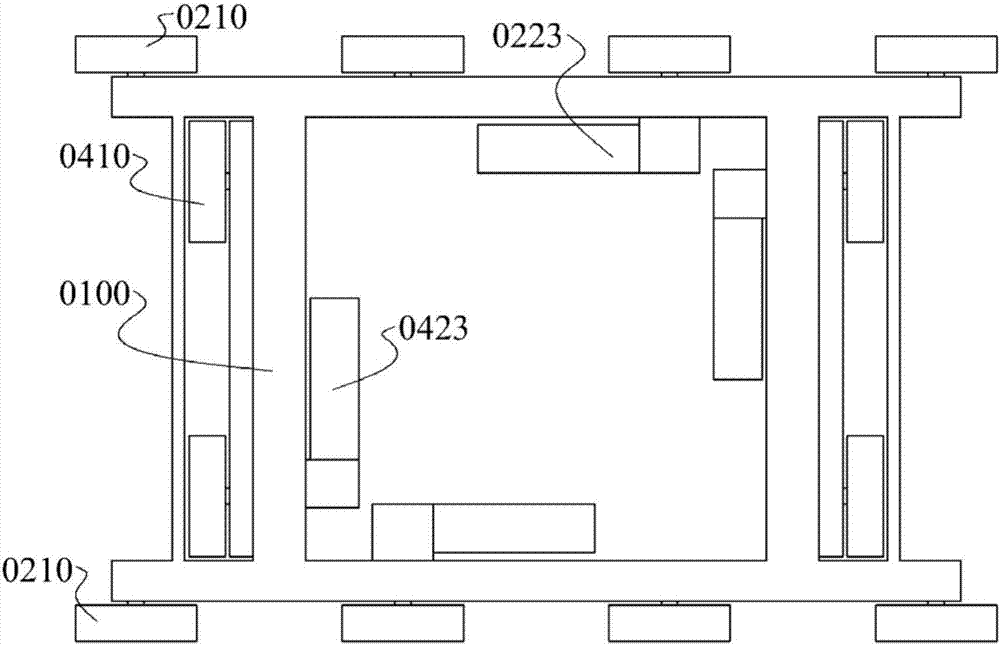

[0036] see figure 1 , the retractable wheeled chassis 1000 has a chassis body 0100 . The chassis body 0100 serves as a support base for the retractable wheeled chassis 1000 and the construction machinery, plays a load-bearing role, and affects the horizontal state of the construction machinery. Generally, the chassis body 0100 should have sufficient structural strength. The chassis body 0100 can adopt various structural forms, such as a truss structure, an integral casting structure, etc. In this embodiment, the chassis body 0100 adopts a hollow frame structure.

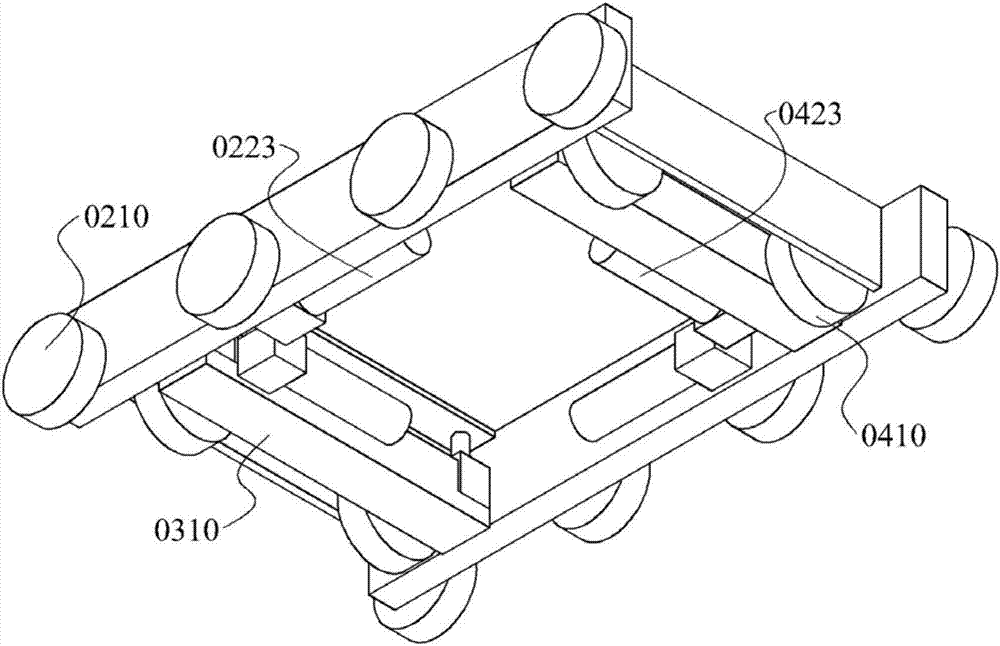

[0037] Please refer to Figure 1~3 , the retractable wheeled chassis 1000 also has a first wheel set 0200, the first wheel set 0200 has a plurality of first moving wheels 0210 arranged axially along the horizontal direction and parallel to each other, and the first moving wheels 0210 are arranged on the chassis body 0100 . The first wheel set 0200 is used to realize the horizontal movement of the retractable whee...

Embodiment 2

[0058] The difference between this embodiment and Embodiment 1 is that in this embodiment, the telescopic moving body 0310 is rotatably held on the chassis body 0100 in the vertical plane.

[0059] Please refer to figure 1 and Image 6 Specifically, one end of the telescopic moving body 0310 is hinged on the chassis body 0100 , and the other end is connected to the second wheel set 0400 . Wherein, the telescopic moving body 0310 is connected with the second moving wheel 0410 in a one-to-one correspondence. Preferably, a motion driving part 0320 is connected to the middle of the telescopic moving body 0310 , and the moving driving part 0320 is used to drive the telescopic moving body 0310 to rotate around the hinged end of the telescopic moving body 0310 and the chassis body 0100 . Among them, the motion driving part 0320 can be in the form of a rotary motor, a linear motor, a cylinder, a hydraulic cylinder, an electric push rod, an electric cylinder, or a hydraulic motor.

...

Embodiment 3

[0062] The difference between this embodiment and Embodiment 1 is that in this embodiment, the chassis body 0100 is provided with a chassis adjustment mechanism 0500 for adjusting the levelness of the chassis body 0100 .

[0063] Please refer to figure 1 and Figure 7 , specifically, the ground of the construction site is mostly still in a rough state, and has certain ups and downs. If only the plurality of first moving wheels 0210 of the first wheel set 0200 are used to support, the levelness of the chassis body 0100 will be along the ground, resulting in insufficient precision, which in turn will affect the work of the construction machinery working department located on the retractable wheeled chassis 1000 precision. The chassis adjustment mechanism 0500 can independently adjust the levelness of the chassis body 0100, and get rid of the inaccurate levelness of the traditional structure.

[0064] Preferably, the chassis adjustment mechanism 0500 has a plurality of telesco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com