Wear-resistant thermocouple processing method and wear-resistant thermocouple

A processing method and thermocouple technology, which is applied in the direction of thermometers that are directly sensitive to heat/magnetic elements, measuring heat, and using electrical devices, etc., can solve the problem of complex drilling, easy drilling deviation, and thermocouple protection sleeves. Tube strength is not high, to achieve the effect of compact structure, reduce wall thickness, improve strength and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for processing a wear-resistant thermocouple, comprising the following steps:

[0023] (1) Blank selection: select the metal tube according to the design requirements of the thermocouple protection sleeve length and the thermocouple wire specification;

[0024] In this step, a metal tube with a certain length and inner and outer diameters is selected according to the length design requirements of the thermocouple protection sleeve and the specifications of the thermocouple wire. The metal tube can be a metal thick-walled tube made of stainless steel, alloy steel, etc. , the wall thickness of the metal pipe should ensure that the inner diameter of the metal pipe can be reduced and eliminated during the hot forging process. Preferably, the ratio of the wall thickness to the outer diameter of the metal pipe is 1 / 3 to 1 / 4, which can ensure that the hot forging The inner diameter of the metal tube is completely eliminated during the diameter process and a dense end ...

Embodiment 2

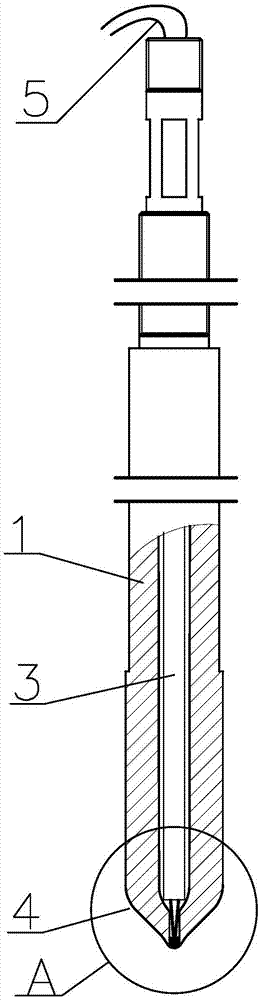

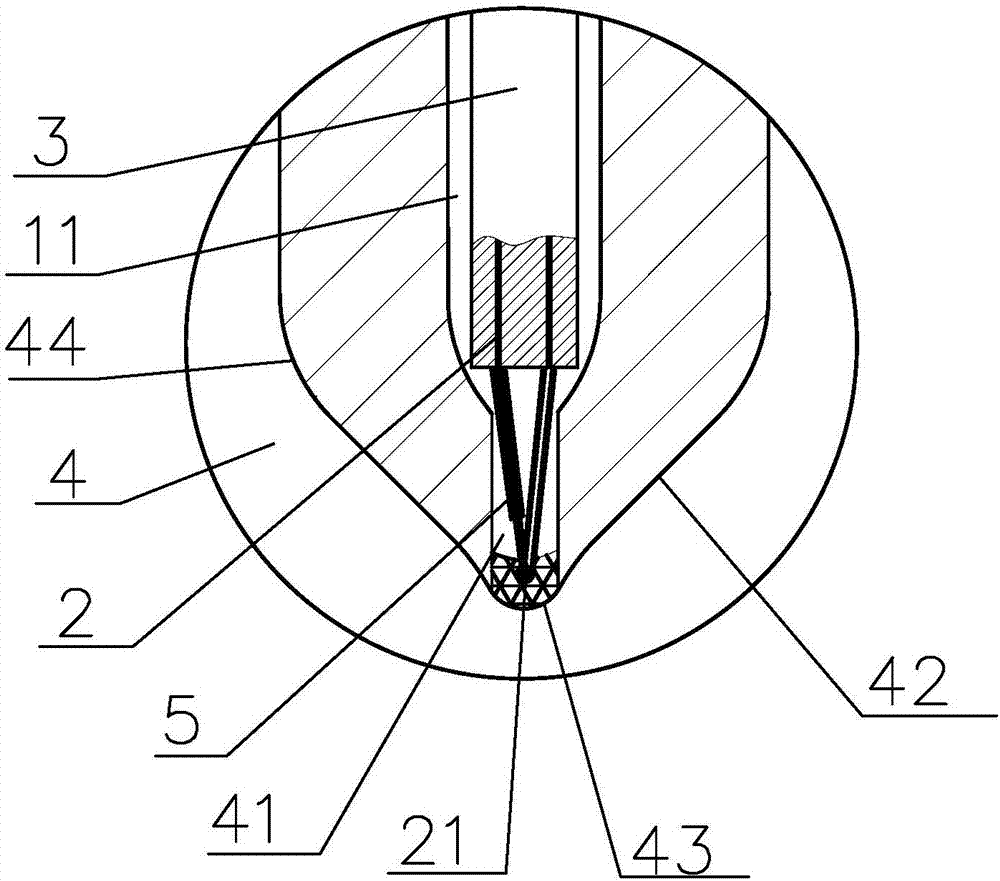

[0034] Such asfigure 1 and figure 2 Shown is a structural diagram of an embodiment of the wear-resistant thermocouple of the present invention, including a protective sleeve 1, a thermocouple wire 2 and a two-hole ceramic tube 3, and the thermocouple wire 2 penetrates into the two-hole ceramic tube 3 and is juxtaposed Inside the protective sleeve 1 , the other end of the thermocouple wire 2 protrudes from the protective sleeve 1 for outputting the temperature measured by the temperature measuring end 21 . The protective sleeve 1 is a sealed bulkhead tube made of a metal tube with one end processed by hot forging and shrinking. The bulky end 4 of the protective sleeve 1 is smooth and excessively curved. The inner hole 11 of the tube is coaxial with the through hole 41 at the bulkhead end, and the temperature measuring end 21 of the thermocouple wire 2 covered with the glass fiber tube 5 penetrates into the through hole 41 at the bulkhead end and is welded with the inner wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com