High-temperature and high-pressure loading device for in-situ neutron diffraction

A technology of high temperature and high pressure, loading device, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problem that X-ray can not get effective results and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

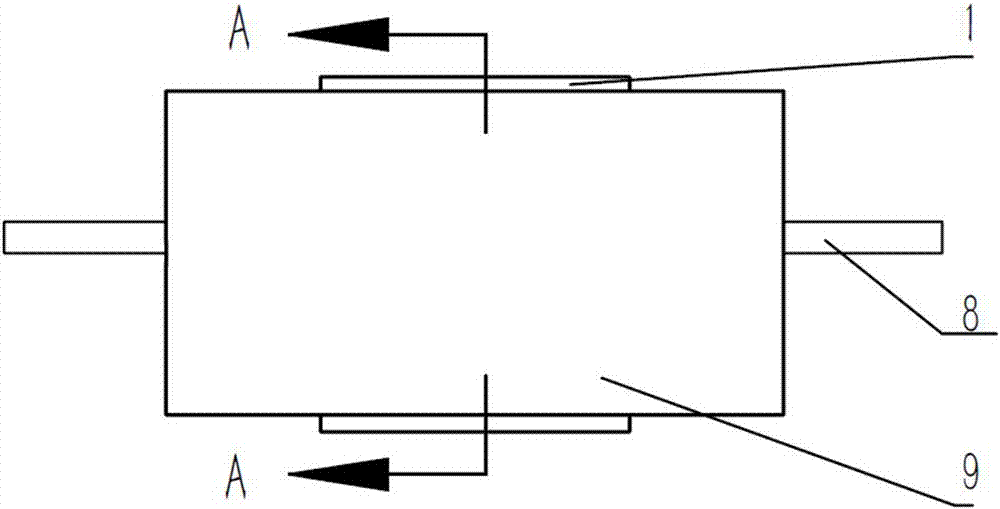

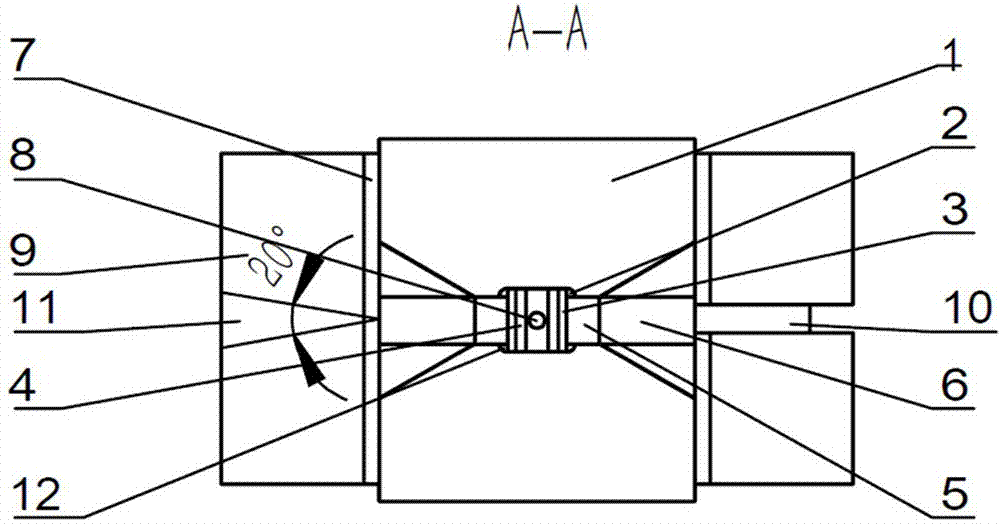

[0025] figure 1 It is the front view of the high temperature and high pressure loading device for in-situ neutron diffraction of the present invention, figure 2 for figure 1 A-A sectional view in . exist figure 1 , figure 2 Among them, the high-temperature and high-pressure loading device of the present invention has a cylindrical shape, including a pressurizing part and a heating part; wherein, the pressurizing part includes an anvil 1, pressure transmission medium I2, pressure transmission medium II12, and pressure transmission medium III5. The heating part includes a graphite tube 3, a magnesium oxide tube 4, and a thermocouple 8 covered with an alumina tube. The connection relationship is that the center of the anvil 1 is provided with a groove, the graphite tube 3 is placed in the groove, the pressure transmission medium I2 is placed in the groove around the upper end of the graphite tube 3, and the pressure transmission medium II12 is placed in the graphite tube 3....

Embodiment 2

[0036] The structure of this embodiment is the same as that of Embodiment 1, except that the material of the anvil 1 is diamond.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com