Ultrasonic measurement system and detection method for detecting deep structural fissures

An ultrasonic measurement and fracture technology, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, analyze materials, instruments, etc., can solve the problems of reduced spatial resolution, conflicting resolution and penetration depth, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

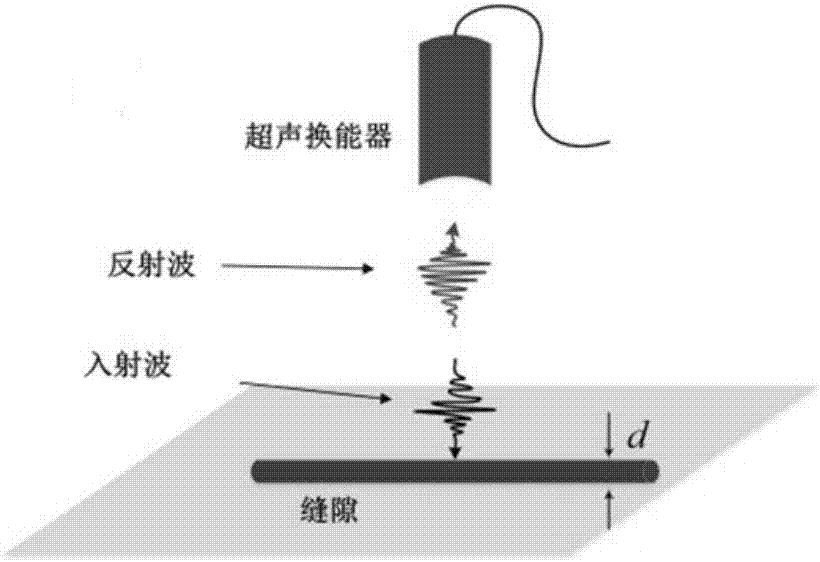

[0107] Example 1: Use metal wires to imitate cracks. The diameters of the metal wires are 60 μm, 100 μm, 150 μm, and 200 μm. They are respectively embedded in agar to make 4 samples with a depth of about 2 cm. Using an ultrasonic transducer with a center frequency of 4.39MHz and a -6dB bandwidth of 4.4MHz, a beam of ultrasonic pulses is emitted. The ultrasonic pulses are reflected and scattered on the wire, and the echo signal is received by the transducer. Using the same system, a beam of ultrasonic pulses is transmitted to a sufficiently large metal surface and the echo signals are received. Figure 4a The power spectrum of the calibrated 150μm diameter metal wire echo signal is given, and the linear fitting is done in the 0.5-8MHz frequency band, and the slope value of the fitting line can be obtained. The inset is the corresponding time-domain signal. Figure 4b Experimental slope values are given for all 4 wire sizes and compare well with theoretical values. Compared ...

example 2

[0108] Example 2: Get the diameters of 60 μm and 150 μm metal wires with a total length of about 20 cm, and cut them into sections with a length of about 1 cm, and then bury these small pieces of metal wires randomly in a certain plane of agar, The depth is about 2cm. The area occupied by the metal wire is about 2×2cm2, wherein, the left half is a 60 μm metal wire, and the right half is a 150 μm metal wire. Using an ultrasonic transducer with a center frequency of 4.39MHz and a -6dB bandwidth of 4.4MHz, a beam of ultrasonic pulses is emitted. The ultrasonic pulses are reflected and scattered on the wire, and the echo signal is received by the transducer. Place the sample horizontally on the stepper motor platform, move 2cm in the x direction and y direction with a step length of 1mm, and detect the area where the metal wire is located, and detect 400 points in total. The calibrated power spectrum of the echo signal measured at each detection position is made respectively, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com