Production and processing system for stone materials

A processing system, stone technology, applied in general control systems, control/regulation systems, program control in sequence/logic controllers, etc., can solve problems such as effective control, low manufacturing efficiency of finished products, difficult quality standards, etc. Good accuracy, improved automation, reduced quantity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

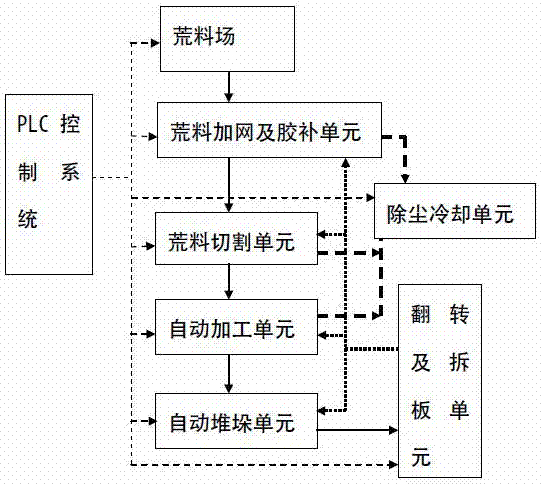

[0012] In order to further illustrate the inventive concept of the present invention, the specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0013] Such as figure 1 As shown, a production and processing system for stone according to the present invention, the production and processing system includes a block yard, a block screening and glue repair unit, a block cutting unit, an automatic processing unit, turning and dismantling A plate unit, a dust removal cooling unit, an automatic stacking unit and a PLC control system, wherein several blocks ores are stacked in the block yard, and the block yard also has an automatic lifting device for lifting the blocks ores;

[0014] The block screening and glue repairing unit is set on one side of the block yard, and the block screening and glue repairing unit includes an automatic screen screening device, an automatic glue spraying device, an automatic drying device a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com