Hydroxypropyl methyl cellulose plant empty capsule

A technology of hydroxypropyl methylcellulose and plant hollow capsules, which is applied in capsule delivery, medical preparations of non-active ingredients, and pharmaceutical formulations, etc., can solve problems hindering the development of pharmaceutical dosage forms, and achieve low loss on drying and destructive Small, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

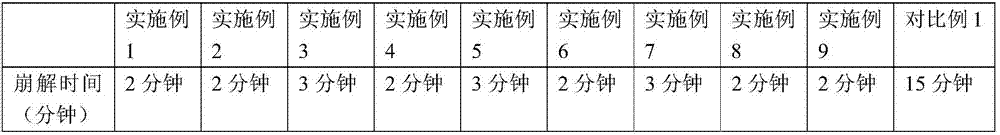

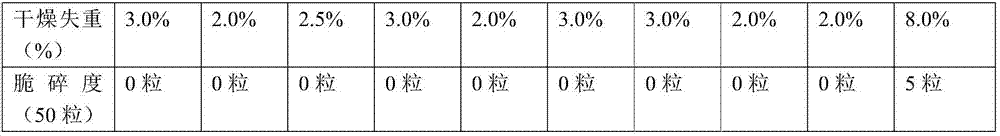

Examples

Embodiment 1

[0022] 1.0kg HPMC is dissolved in the mixed solvent of 80% acetone and 20% water by volume fraction, is mixed with the HPMC solution that mass fraction is 10%, then makes 10% HPMC solution go through into capsule process.

[0023] Capsulation process comprises the following steps:

[0024] 1) Under normal temperature and pressure, put 10% HPMC solution into the sol tank, and keep stirring to make a glue solution. During this process, the sol tank does not need to be heated or vacuumized;

[0025] 2) Filter the glue in the sol tank through the filter bag into the glue barrel, and the glue in the glue barrel will go through color matching, standing, airtight and natural defoaming in order to prepare before dipping in glue;

[0026] 3) Pour the glue after natural defoaming into the glue tray, the temperature of the glue tray is 20-30°C, and then use the mold to dip the glue in the glue tray to prepare the sample. Through the continuous volatilization of the organic solvent aceton...

Embodiment 2

[0029] 1.0kg HPMC is dissolved in the mixed solvent of 90% acetone and 10% water by volume fraction, is mixed with mass fraction and is the HPMC solution of 33%, then makes the HPMC solution of 33% through the capsule-making described in embodiment 1 process.

Embodiment 3

[0031] 1.0kg HPMC is dissolved in the mixed solvent of 85% acetone and 15% water by volume fraction, is mixed with mass fraction and is the HPMC solution of 20%, then makes the HPMC solution of 20% through the capsule-making described in embodiment 1 process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com