A modified adobe material and a construction method for filling a traditional empty bucket wall

A construction method and wall technology, applied to walls, building components, buildings, etc., can solve problems such as thermal insulation, sound insulation effects are not very ideal, limit the wide application of empty bucket walls, and the wall is self-heavy, so as to improve the solidity performance and stability, improve the thermal comfort environment, and improve the effect of poor thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

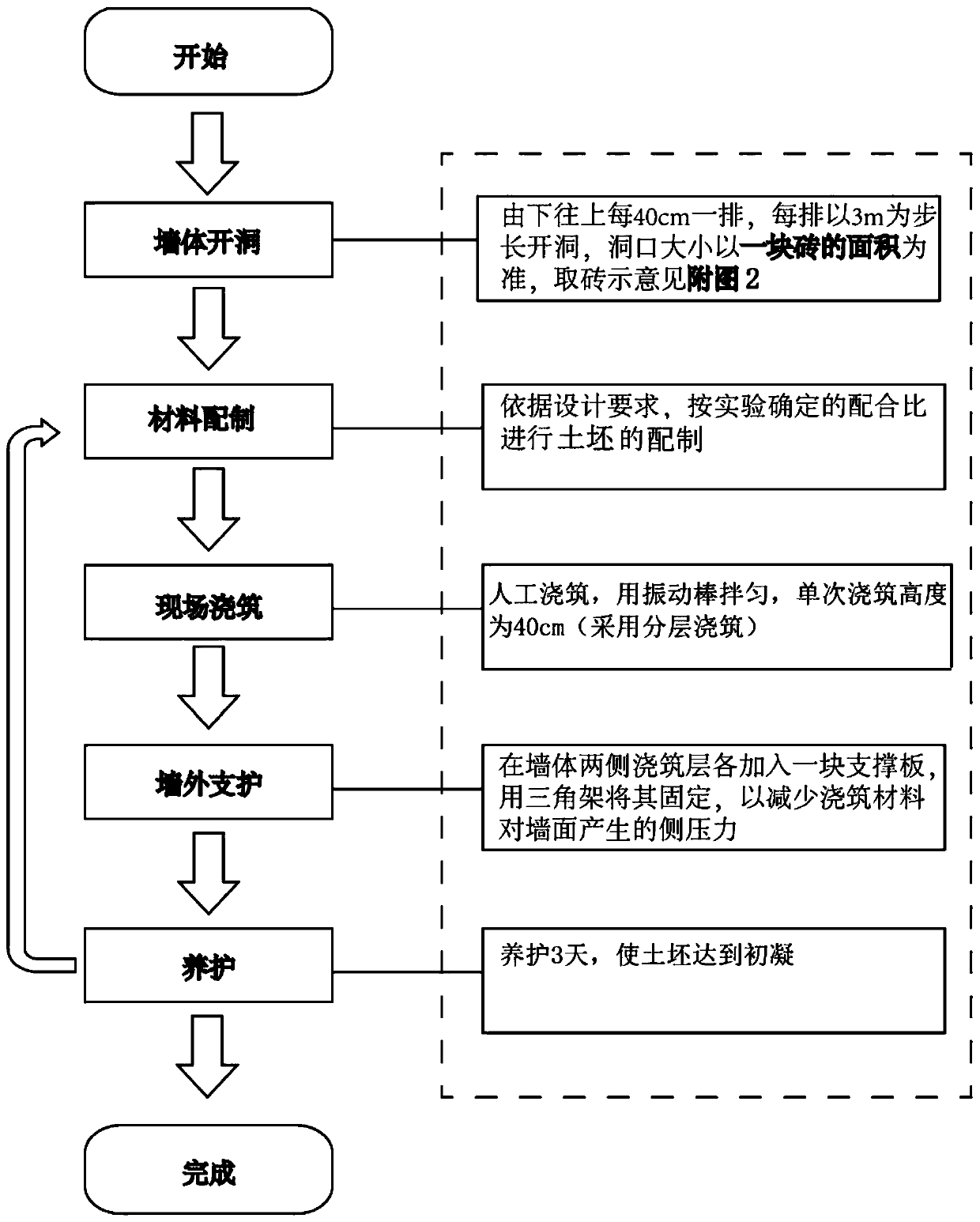

[0050] see image 3 As shown, a construction method of using modified adobe material to fill the traditional empty bucket wall, the steps are as follows:

[0051] ① Hole in the wall

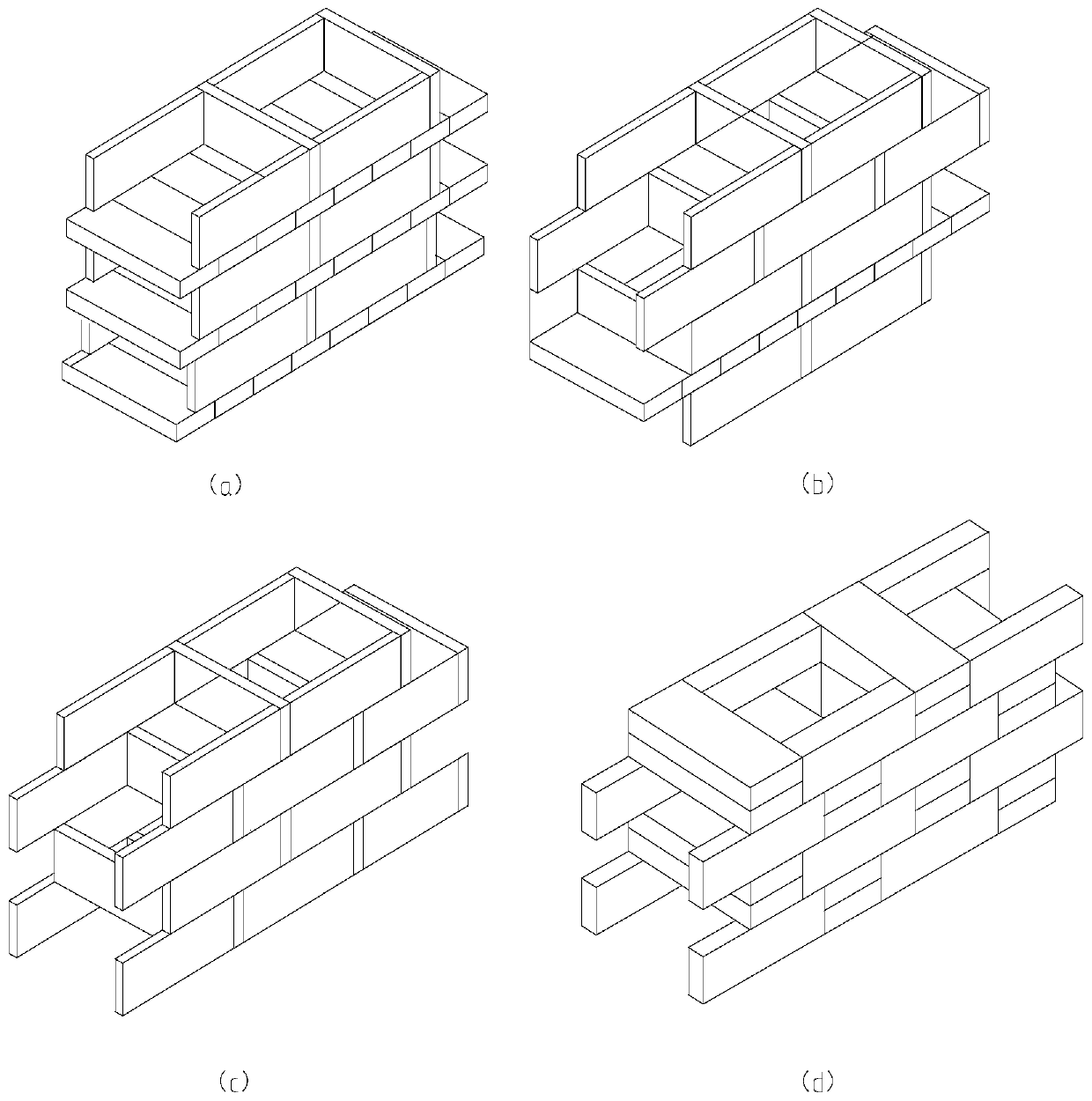

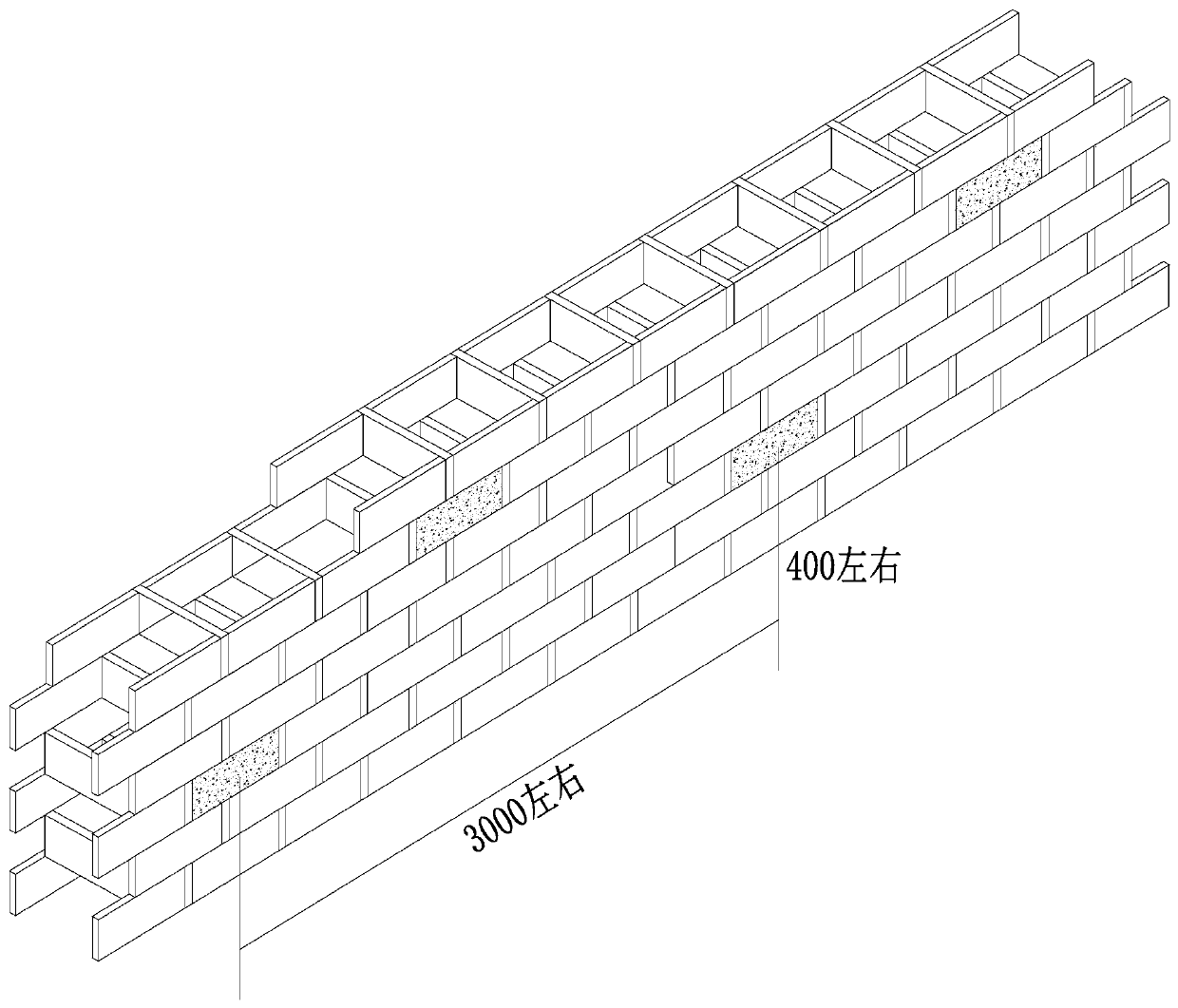

[0052] see figure 2 As shown, taking the empty bucket wall of the full-bucket sleepless masonry method as an example, a row of bricks is taken every 40cm from bottom to top on the wall, and each row takes 3m as a step to open holes. The horizontal distance between adjacent holes in the direction is 1.5m.

[0053] ② Preparation of modified adobe materials

[0054] a. Preparation and ratio of construction materials

[0055] 1) Main construction materials

[0056] (1) Slaked lime: meet the requirements of JC / T 481-2013 "Slaked lime for construction".

[0057] (2) Fly ash: It meets the requirements of Class II fly ash in GB / T 50146-2014 "Technical Specifications for the Application of Fly Ash Concrete".

[0058] (2) Soil: Loess with high viscosity should be selected, with local clay as the ma...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap