Extracting method of eaglewood essential oil

A kind of agarwood essential oil and extraction method technology, applied in the directions of essential oil/spice, fat generation, etc., can solve the problems of solvent residue, time-consuming, clean removal, etc., and achieve the effects of short time-consuming, low operating cost, and mild technical conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The present embodiment provides a kind of extracting method of agarwood essential oil, specifically comprising:

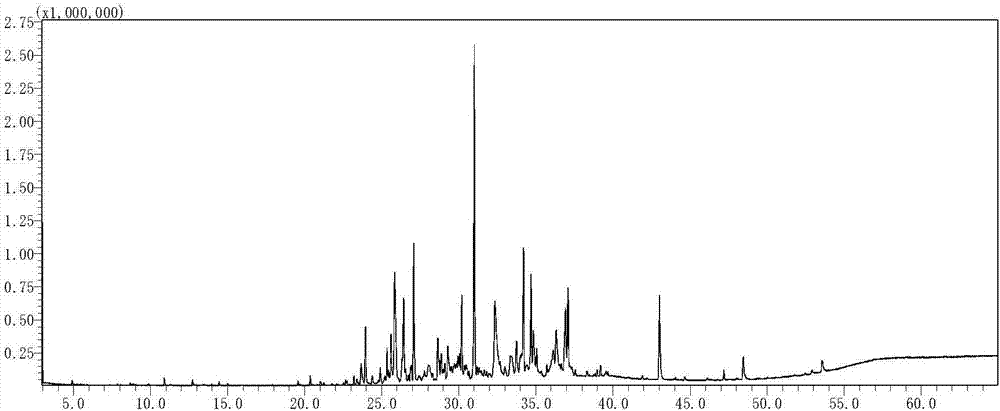

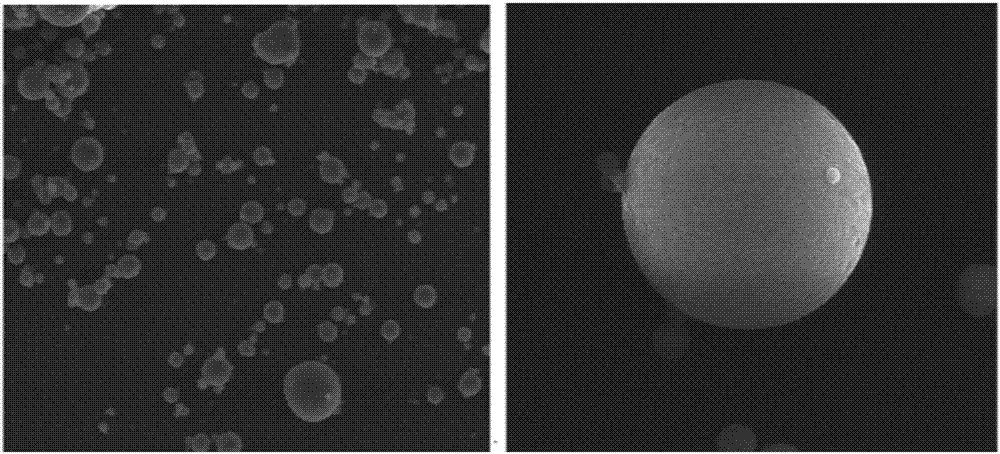

[0044] Grind agarwood into powder with an average particle size of 60 mesh, put the raw material powder into the extraction kettle; input subcritical butane fluid into the extraction kettle, the extraction pressure is 0.5MPa, the extraction temperature is 60°C, and the extraction time is 0.6 h, the analysis temperature is 25°C; the subcritical butane fluid dissolved with the extract is analyzed and separated to obtain the agarwood extract; the agarwood extract is subjected to microfiltration, the filter membrane pore size is 1.0 μm, and the filtration temperature is 70°C. The pressure is 0.2 MPa. Collect the filtrate from the previous step to obtain high-purity agarwood essential oil. The agarwood essential oil is embedded in sodium alginate and gelatin, and freeze-dried to obtain the agarwood essential oil sustained-release capsule.

Embodiment 2

[0046] The present embodiment provides a kind of extracting method of agarwood essential oil, specifically comprising:

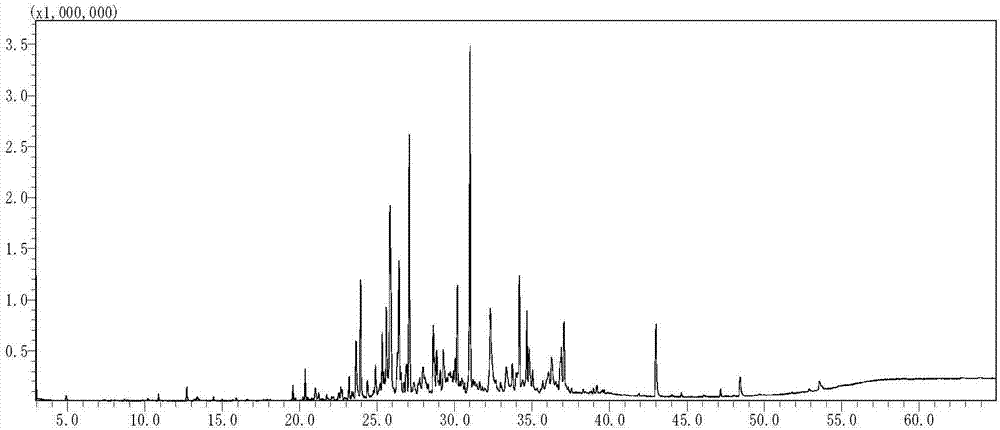

[0047] Grind agarwood into powder with an average particle size of 70 mesh, put the raw material powder into the extraction kettle; input subcritical butane fluid into the extraction kettle, the extraction pressure is 0.6MPa, the extraction temperature is 40°C, and the extraction time is 1h , the analysis temperature is 50°C; the subcritical butane fluid dissolved with extracts is analyzed and separated to obtain agarwood extract; the agarwood extract is subjected to microfiltration, the filter membrane pore size is 0.2 μm, the filtration temperature is 50°C, and the filtration pressure is 0.6MPa. Collect the filtrate from the previous step to obtain high-purity agarwood essential oil. The agarwood essential oil is embedded in sodium alginate and gelatin, and freeze-dried to obtain the agarwood essential oil sustained-release capsule.

Embodiment 3

[0049] The present embodiment provides a kind of extracting method of agarwood essential oil, specifically comprising:

[0050] Grind agarwood into powder with an average particle size of 50 mesh, put the raw material powder into the extraction kettle; input subcritical butane fluid into the extraction kettle, the extraction pressure is 0.4MPa, the extraction temperature is 46°C, and the extraction time is 0.4 h, the analysis temperature is 40°C; the subcritical butane fluid dissolved with the extract is analyzed and separated to obtain the agarwood extract; the agarwood extract is subjected to microfiltration, the filter membrane pore size is 0.6 μm, and the filtration temperature is 60°C. The pressure is 0.5MPa. Collect the filtrate from the previous step to obtain high-purity agarwood essential oil. The agarwood essential oil is embedded in sodium alginate and gelatin, and freeze-dried to obtain the agarwood essential oil sustained-release capsule.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com