Structural steel for polar ice-breaking transport ship and its manufacturing method

A technology for structural steel and manufacturing methods, applied in the field of structural steel and manufacturing for polar ice-breaking transport ships, can solve the problems that ice-breaking ships have no large-scale cargo transportation capacity, low-temperature ships cannot break ice, etc., achieve great significance, shorten the voyage, and have high safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the examples to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

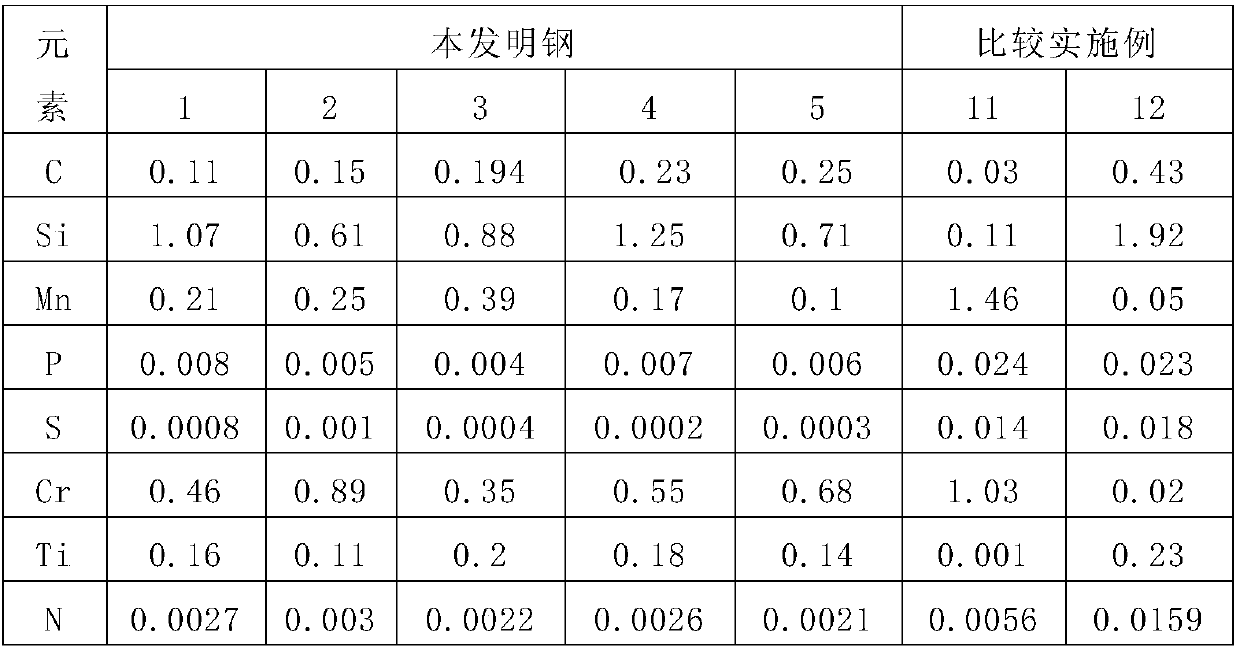

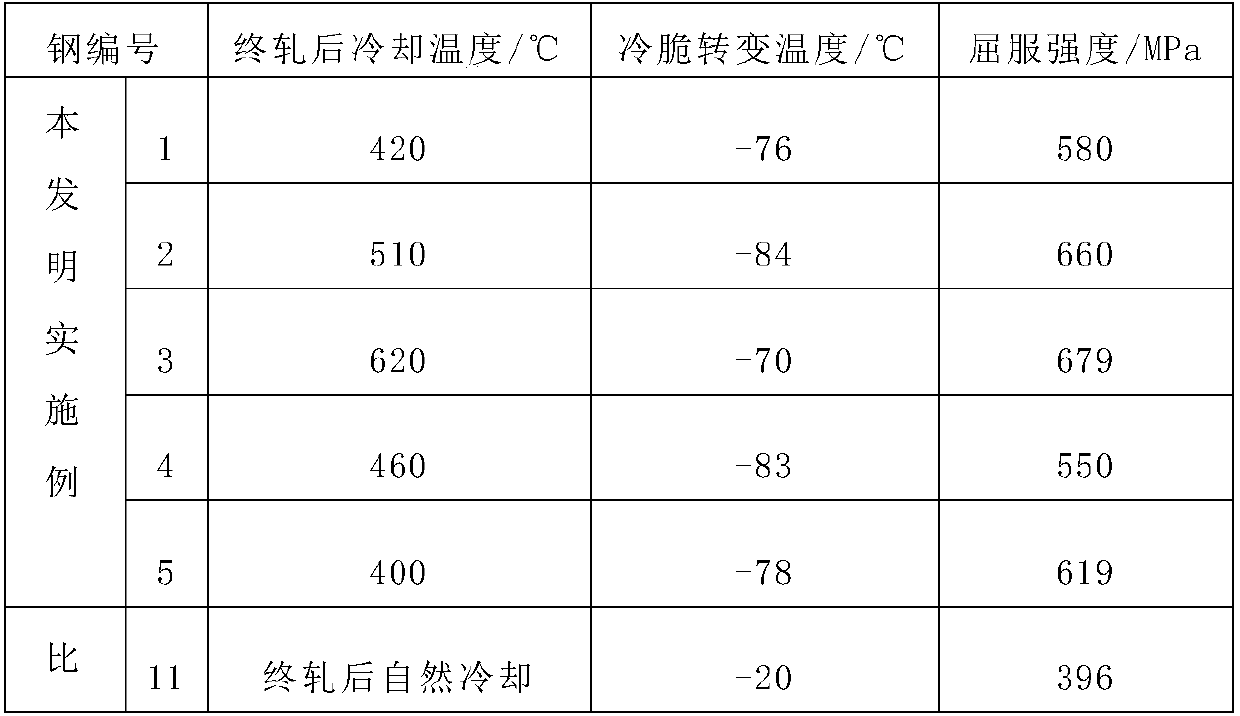

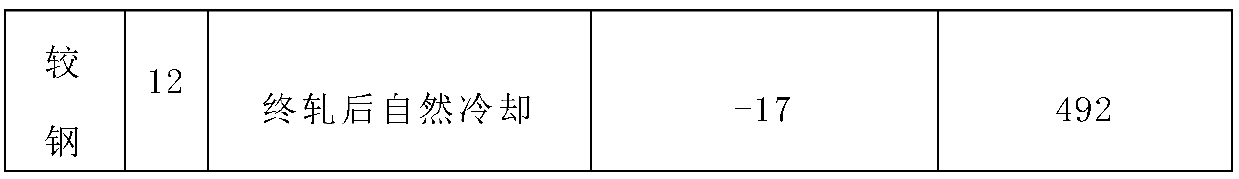

[0030] According to the chemical element composition, weight percentage and production method requirements of the present invention, prepared five embodiments, and two comparative examples, respectively embodiment 1, embodiment 2, embodiment 3, embodiment 4, embodiment 5, Comparative Example 1 and Comparative Example 2, that is, 7 batches of steel plates were smelted and rolled. The weight percentages of the chemical elements of the five examples and two comparative examples are shown in Table 1, wherein the balance is Fe and unavoidable impurities. The production process control parameters and steel plate quality are shown in Table 2.

[0031] The chemical composition contrast (wt %) of five embodiments of table 1 and two comparative examples

[0032]

[0033]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com