Spray coating equipment capable of being converted between normal pressure and low pressure

A spraying equipment and low-pressure technology, which is applied in the direction of coating, fusion spraying, pressure inorganic powder coating, etc., to achieve the effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings. In the description of the spraying equipment switchable between normal pressure and low pressure of the present invention, it should be understood that terms such as "front", "rear", "upper", "lower", "front", "back" are only It is for the convenience of describing the technical solution of the present invention, rather than indicating that the referred device or element must have a specific orientation, so it should not be construed as a limitation of the present invention.

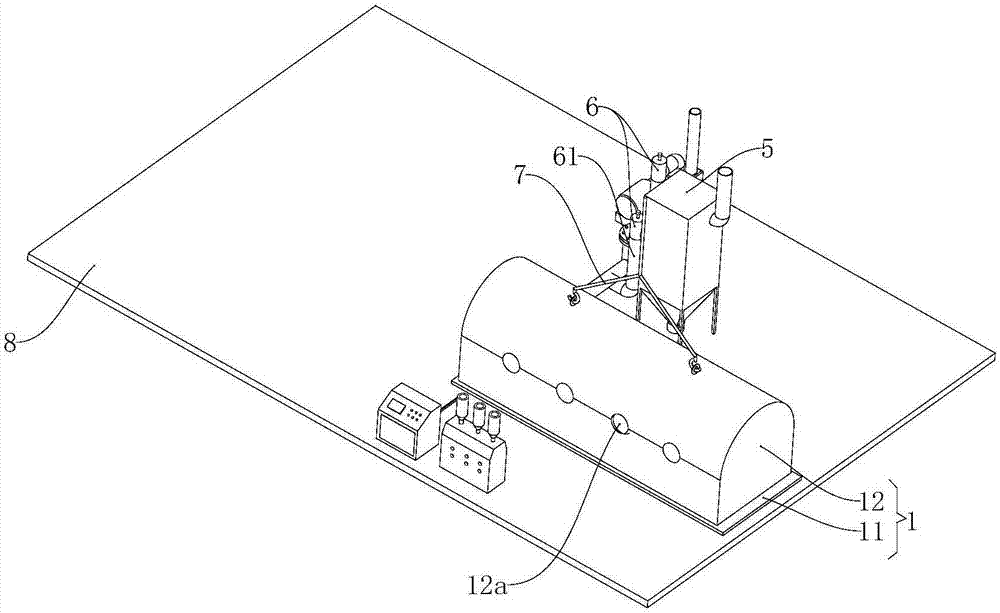

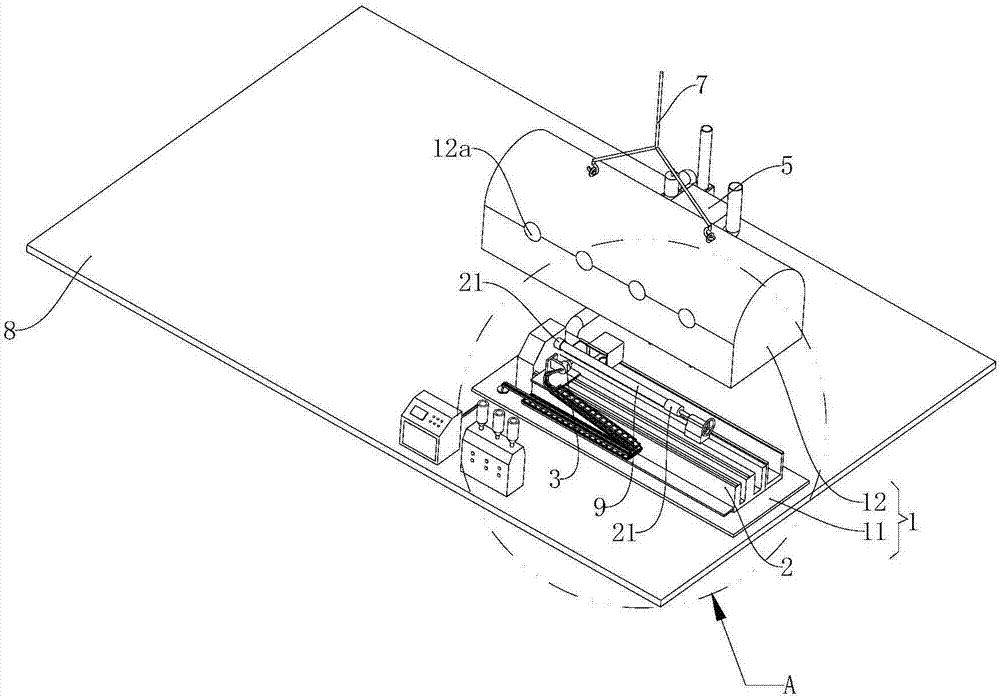

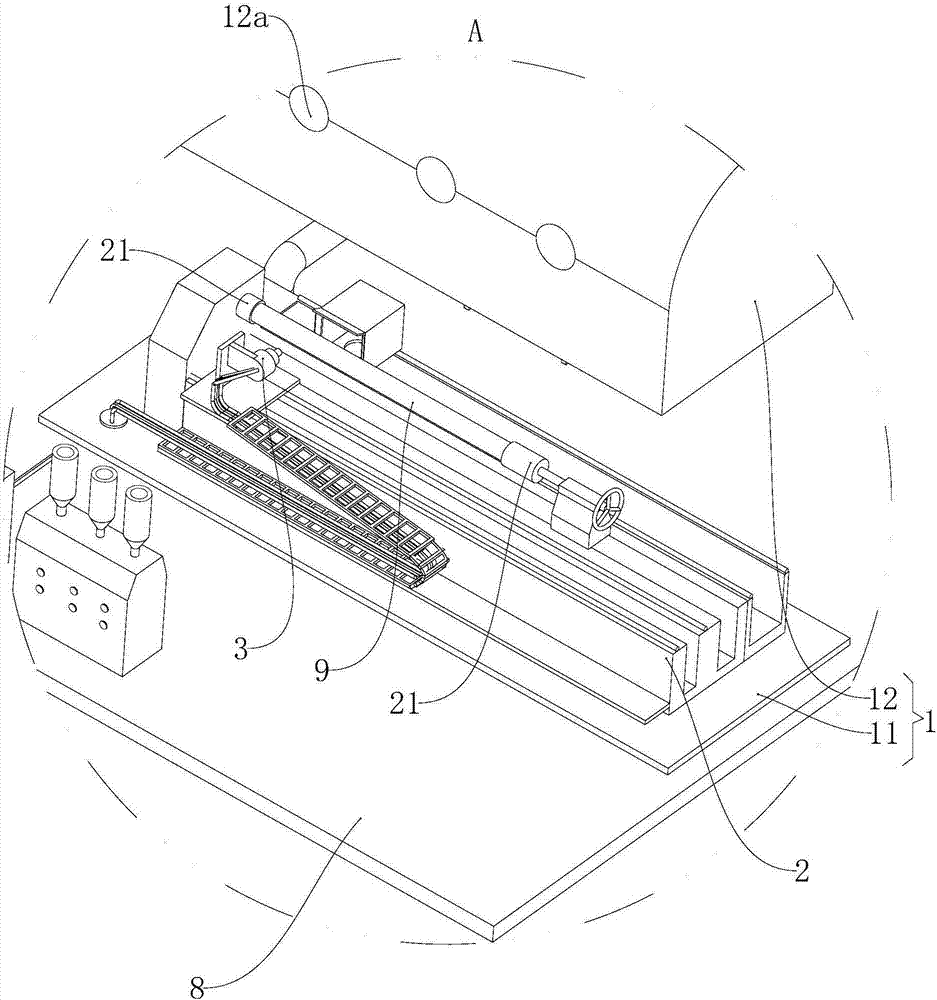

[0030] Such as Figure 1-7 Shown, the spray equipment that can switch between normal pressure and low pressure of the present invention comprises:

[0031] The spray booth 1 includes a base 11 and a seal cover 12 detachably covered on the base 11. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap