Aroma-releasing fabric and preparation method thereof

A technology for fabric and fragrance release, which is applied in the direction of fabric, textile, knitting, etc. It can solve the problems of poor fragrance persistence and difficulty in long-term retention, and achieve the effects of enhancing long-lasting release, improving long-lasting release, and improving richness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

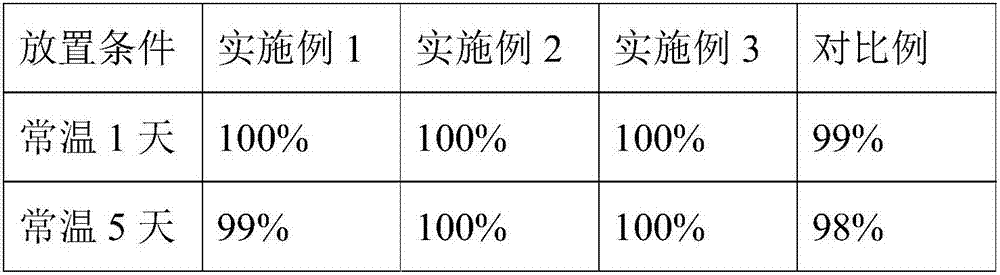

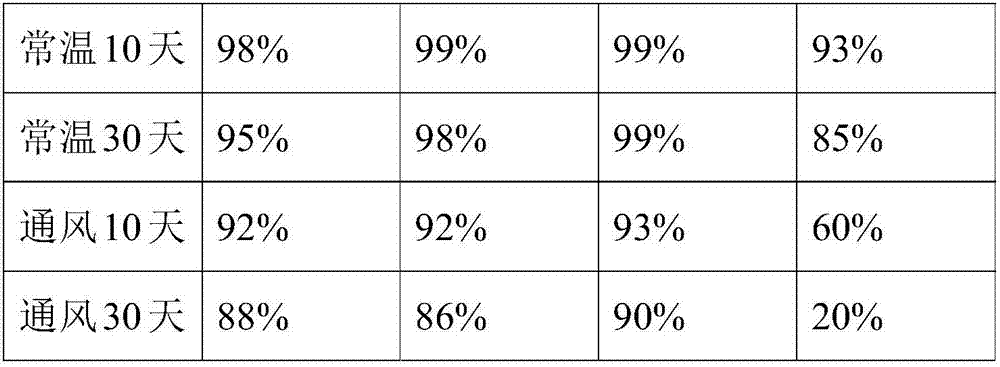

Embodiment 1

[0026] A fragrance-releasing fabric prepared by the following method:

[0027] (1) Disperse 0.1 mol / L carbon nanotubes in a solution of 3 mol / L sodium dodecylbenzene sulfonate, then add 0.02 mol / L coupling agent, and spray-dry at 150°C to obtain dodecyl Carbon nanotubes modified by sodium benzene sulfonate;

[0028] (2) Mix the carbon nanotubes modified with sodium dodecylbenzene sulfonate with a mass ratio of 0.1:5 and bamboo fibers, stir, add titanate coupling agent to react, after the reaction is completed, wash, and dry to obtain bamboo fibers. The product of the carbon nanotubes modified by sodium dodecylbenzene sulfonate; the added amount of the coupling agent is 0.07wt% of the mass of the carbon nanotubes modified by sodium dodecylbenzene sulfonate;

[0029] (3) Disperse the bamboo fiber grafted carbon nanotubes modified by sodium dodecylbenzene sulfonate obtained in step (2) in an indole solution (10w% indole), and irradiate 50W microwave for 40 minutes to obtain Bamboo fib...

Embodiment 2

[0034] A fragrance-releasing fabric prepared by the following method:

[0035] (1) Disperse 0.3 mol / L carbon nanotubes in a solution of 1-3 mol / L sodium dodecylbenzene sulfonate, then add 0.02 mol / L coupling agent, and spray-dry at 120-150°C. Sodium dodecylbenzene sulfonate modified carbon nanotubes;

[0036] (2) Mix the carbon nanotubes modified by sodium dodecylbenzene sulfonate with a mass ratio of 0.5:3 and bamboo fibers, stir, add titanate coupling agent to react, after the reaction is completed, wash, and dry to obtain bamboo fibers. The product of the carbon nanotubes modified by sodium dodecylbenzene sulfonate; the added amount of the coupling agent is 0.01wt% of the mass of the carbon nanotubes modified by sodium dodecylbenzene sulfonate;

[0037] (3) Disperse the bamboo fiber grafted carbon nanotubes modified with sodium dodecylbenzene sulfonate obtained in step (2) in an indole solution (10w% indole), and irradiate 150W microwave for 20 minutes to obtain Bamboo fiber emb...

Embodiment 3

[0042] A fragrance-releasing fabric prepared by the following method:

[0043] (1) Disperse 0.2mol / L carbon nanotubes in a solution of 2mol / L sodium dodecylbenzene sulfonate, then add 0.03mol / L coupling agent and spray dry at 140℃ to obtain dodecyl Carbon nanotubes modified by sodium benzene sulfonate;

[0044] (2) Mix the carbon nanotubes modified by sodium dodecylbenzene sulfonate with a mass ratio of 0.3:4 and bamboo fibers, stir, add titanate coupling agent to react, after the reaction is completed, wash, and dry to obtain bamboo fibers. The product of carbon nanotubes modified by sodium dodecylbenzene sulfonate; the added amount of the coupling agent is 0.04wt% of the mass of the carbon nanotubes modified by sodium dodecylbenzene sulfonate;

[0045] (3) Disperse the bamboo fiber grafted carbon nanotubes modified with sodium dodecylbenzene sulfonate obtained in step (2) in an indole solution (10w% indole), and irradiate 80W microwave for 30 minutes to obtain Bamboo fiber embedd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com