Semiconductor junction temperature test device and test method thereof

A test device and semiconductor technology, applied in single semiconductor device testing, diode testing, etc., can solve the problems of inability to evaluate the real performance of semiconductors, probes that cannot be attached to the surface, and inaccurate temperature collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

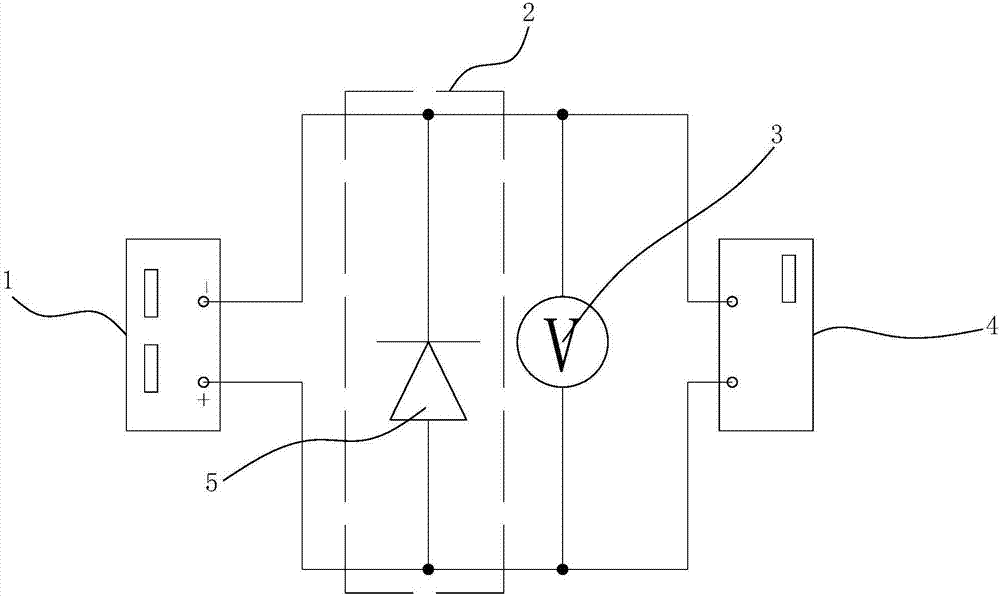

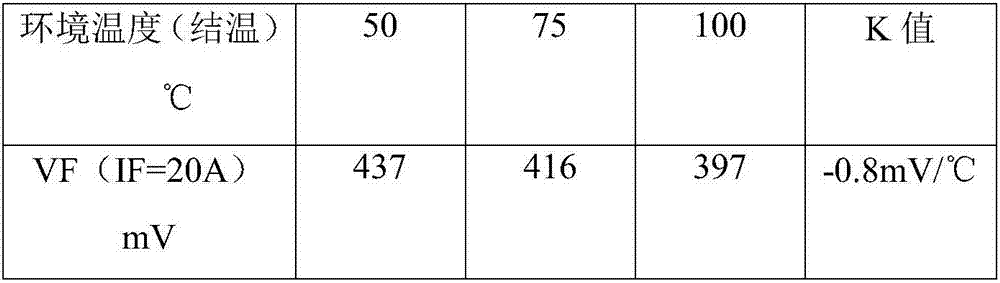

[0034] As shown in the figure, the present invention is a semiconductor junction temperature testing device, which includes a diode installation position 5 and a constant current source 1, the diode installation position 5 is connected to the constant current source 1, and a voltmeter 3 is connected in parallel at both ends of the diode installation position, The diode placement is set in the oven 2; it also includes a semiconductor characteristic tester 4, the semiconductor characteristic tester is connected in parallel to both ends of the diode placement, and a diode is arranged on the diode placement. When in use, place the semiconductor diode on the diode placement position, use a constant current source to provide a constant current, and the oven provides a stable ambient temperature. When the semiconductor diode is placed in the oven for a long enough time, the junction temperature of the semiconductor diode is consistent with the temperature of the oven. At this time, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com