Faraday shield and reaction chamber

A Faraday shielding and reaction chamber technology, applied to electrical components, discharge tubes, circuits, etc., can solve problems such as high temperature and increase the risk of particle contamination in the reaction chamber 1, so as to avoid excessive temperature and reduce Risk of particle contamination, effect of increasing overall coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

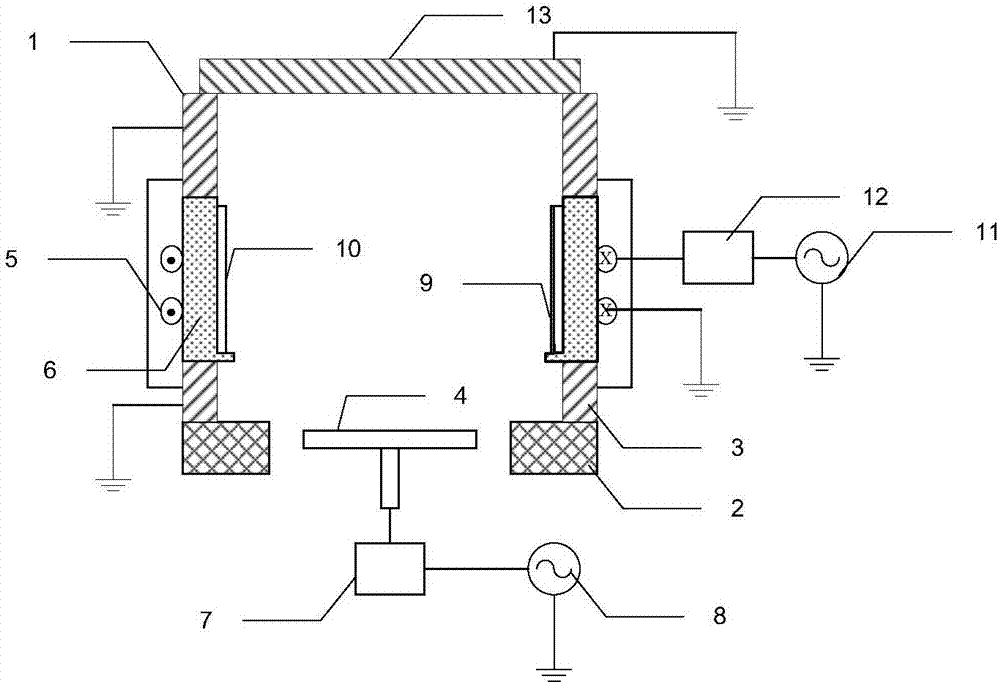

[0055] In order for those skilled in the art to better understand the technical solution of the present invention, the Faraday shield and the reaction chamber provided by the present invention will be described in detail below with reference to the accompanying drawings.

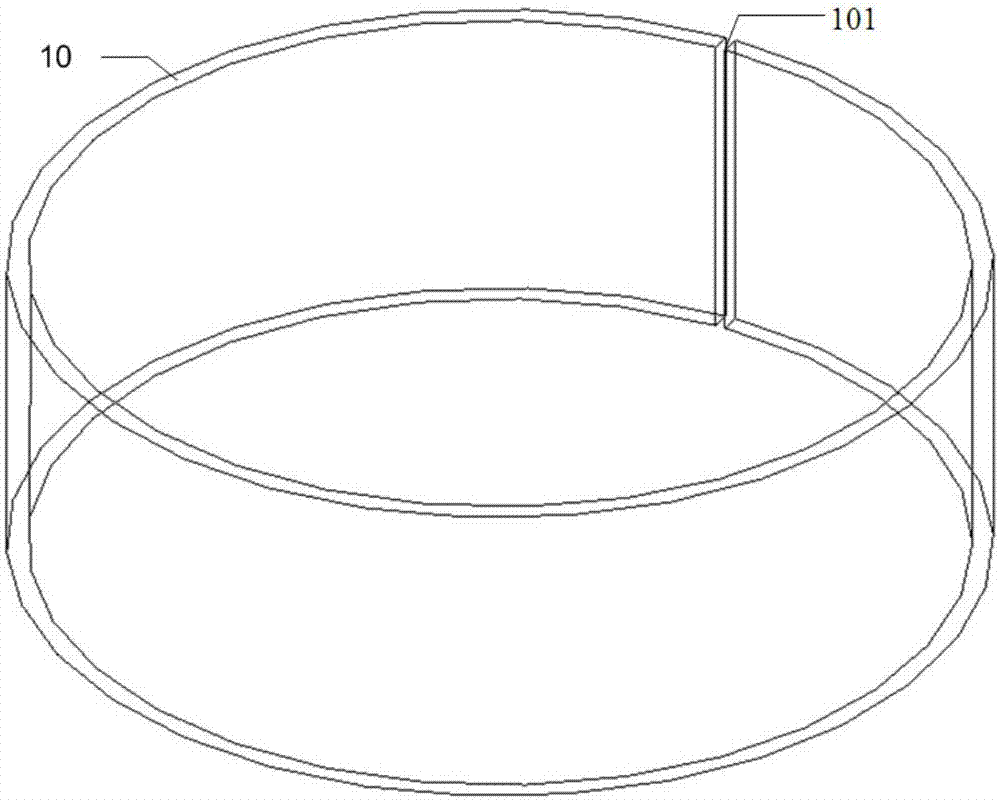

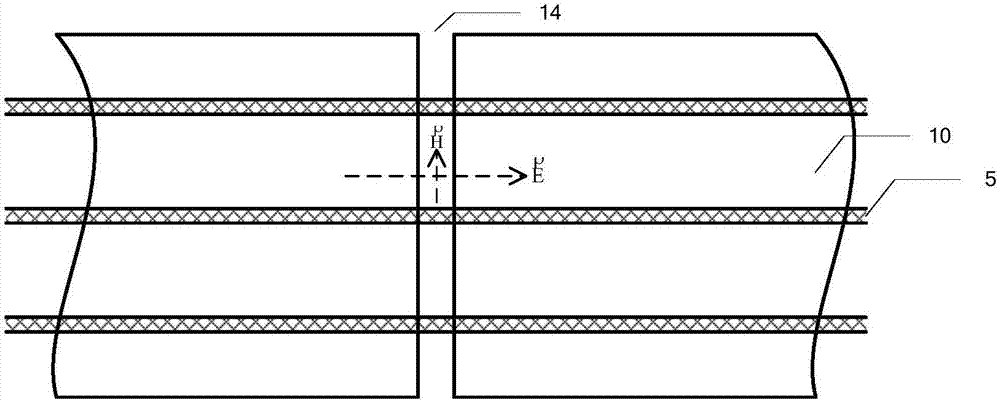

[0056] Please also refer to Figure 4A with Figure 4B , the Faraday shield provided by the first embodiment of the present invention includes a conductive ring body 11, and a slit is formed on the conductive ring body 11, and the slit includes a first sub-slit 111, and the first sub-slit 111 It is arranged along the circumferential direction of the conductive ring body, and forms an included angle a with the axis of the conductive ring body 11 . The electromagnetic field generated by the radio frequency coil 13 surrounding the conductive ring 11 can be divided into a magnetic field component A in the axial direction of the conductive ring 11 and an electric field component B in the circumferential directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com