A kind of ptc liquid heater and its heating control method

A liquid heater and heating control technology, applied in heating/cooling equipment, vehicle parts, transportation and packaging, etc., can solve the problem of PTC heating module not working, etc., to reduce the size of the control cabin, the control method is safe, and the comfort is good Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

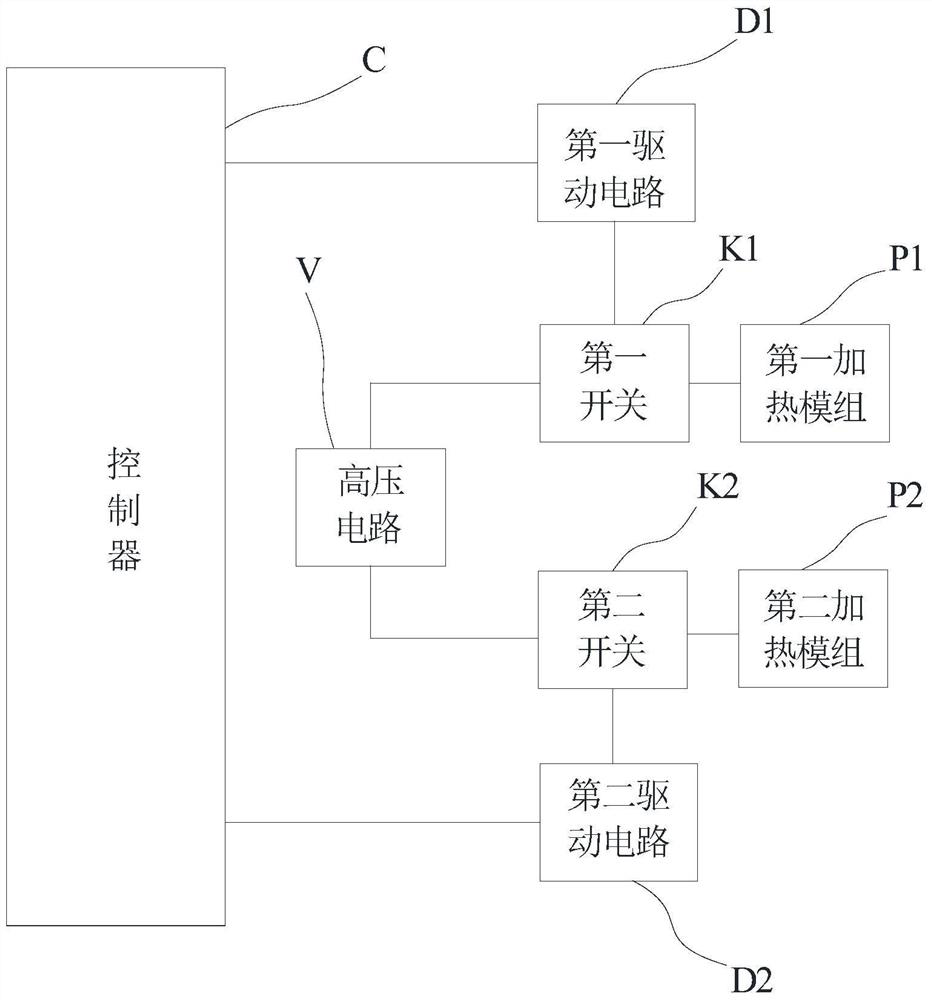

[0060] This example will specifically explain the PTC liquid heater disclosed in the present invention. Such as figure 1 In the block diagram shown, the PTC liquid heater includes a first heating module P1, a second heating module P2, a first switch K1, a second switch, a first drive circuit D1, a second drive circuit D2, a high voltage circuit V and a control Device C;

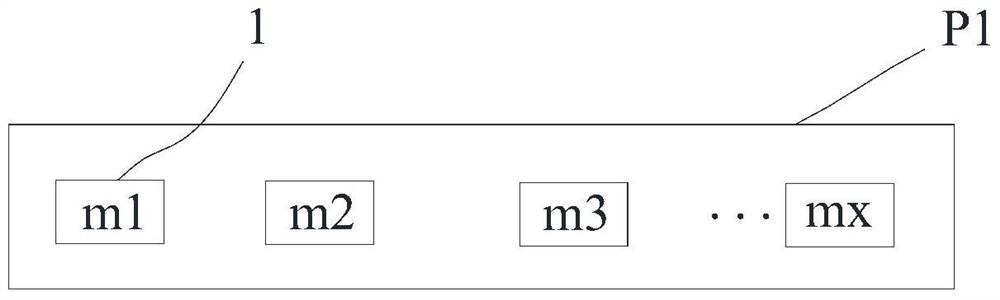

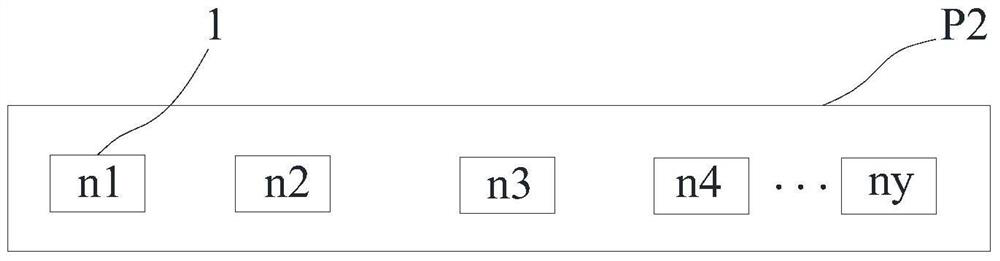

[0061] Among them, such as figure 2 As shown, the first heating module P1 includes x PTC heating modules 1 connected in parallel; for example, m1, m2, m3...mx are marked in the figure with a total of x PTC heating modules 1; as image 3 As shown, the second heating module P2 includes y PTC heating modules 1 connected in parallel, for example, n1, n2, n3, n4...ny are marked n1, n2, n3, n4... ny PTC heating modules 1 in total; wherein, the above-mentioned values of x and y Determined by the heating power of the PTC liquid heater, as a preferred method, in this example, x≤y;

[0062] The above-mentioned P...

Embodiment 2

[0086] This example will specifically explain the heating control method of the above-mentioned PTC liquid heater disclosed in Example 1. The heating control method includes the following steps:

[0087] Such as Figure 7 As shown, the controller C receives the PWM temperature control signal; specifically, as described in Embodiment 1 above, the PWM temperature control signal comes from the ACCU.

[0088] Please understand here that it is a dynamic process for the controller C to receive the PWM temperature control signal. It continuously samples the current temperature T1 and the air outlet speed of the air conditioner within the set period, and obtains the set temperature T0 input by the user in real time. That is, when sending the first logic signal and the second logic signal to the first driving circuit D1 and the second driving circuit D2 later, it is also adjusted dynamically following the above PWM temperature control signal.

[0089] It converts the PWM temperature c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com