Combined set for anchoring and connecting FRP ribs

A kit and anchoring technology, which is applied to the processing of building components, building reinforcements, and building materials, can solve problems such as unstable quality, long production cycle, and shear damage of FRP tendon fibers, so as to solve the problems of difficult bending and anchoring, The effect of solving connection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

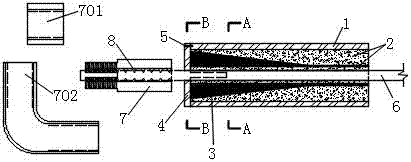

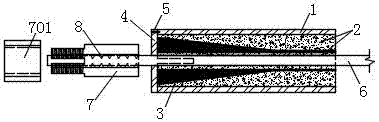

[0031] Such as figure 2 As shown, the combined kit for anchoring the end of the FRP tendon (6) includes a casing (1), an adhesive for filling the casing (2), a tapered sleeve (3) set inside the casing, and a gasket ( 4), screws (5), FRP ribs (6), fastening bolts (7), and nuts (701) matching the fastening bolts (7).

[0032] The FRP tendon (6) is bonded to the tapered sleeve (3), and the left end of the tapered sleeve is provided with a slot. The FRP tendon (6) needs to extend a certain distance to the left end, and then put it into the sleeve (1), and Cover the gasket (4), fix it with the screw (5), inject the suitable adhesive (2) into the casing until the whole device is filled, wait for drying, and then screw the fastening bolt (7) into the FRP rib ( 6), fasten with the nut (701). At this time, note that the FRP tendon (6) at the thread should be wrapped with gauze dipped in adhesive for 2~3 layers, and then screw the nut (701) to prevent the FRP tendon from (6) Damage. ...

Embodiment 2

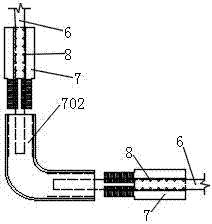

[0034] Such as image 3 , Figure 4 , Figure 5 As shown, the multi-angle connection device for FRP tendons (6) includes fastening bolts (7), and internally threaded connecting pipes (702) for multi-angle connection of FRP tendons (6).

[0035] Screw the FRP tendon (6) into the two fastening bolts (7), and then use the multi-angle connecting pipe (702) with internal thread to connect the FRP tendon (6) to tighten and anchor. At this time, pay attention to the FRP tendon at the fastening place (6) It should be wrapped with gauze dipped in adhesive for 2~3 layers, and then screwed into both ends of the connecting pipe.

Embodiment 3

[0037] Such as Figure 6 and Figure 7 As shown, the concrete structure FRP tendon (6) anchoring device includes fastening bolts (7), nuts (701) or anchor plates (703).

[0038] In the concrete structure, FRP tendons (6) are provided, and the anchoring method can adopt the anchoring method in which the anchoring body is a nut (701) or an anchor plate (703). The FRP tendons (6) are inserted into the fastening bolts (7), and fastened with nuts (701) or anchor plates (703) to achieve the best anchoring effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com