A method for improving mould resistance and ageing resistance of plaited bamboo products

An anti-aging and product technology, which is applied in the manufacture of tools, devices for coating liquid on the surface, reed/straw treatment, etc., can solve the problems of reduced effect, easy to be corroded by mold, pests, etc., and easy to crack, etc., to achieve good results Economic benefits, improve mold resistance and anti-aging ability, prolong service life and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

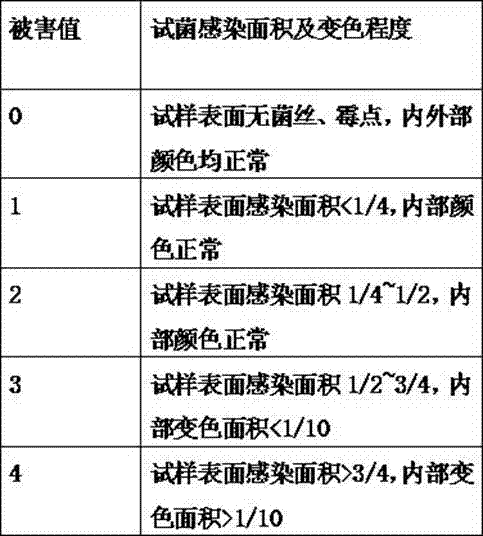

Image

Examples

Embodiment 1

[0026] A method for improving the anti-mildew and anti-aging characteristics of bamboo products, comprising the steps of:

[0027] (1) Polishing treatment:

[0028] Grinding and polishing the woven bamboo products for later use;

[0029] (2) Cooking treatment:

[0030] Put the bamboo woven product treated in step (1) into a pot filled with cooking liquid, heat to keep the temperature of the cooking liquid at 60°C, take it out after cooking for 20 minutes, and cool it down to room temperature naturally for later use; in the cooking liquid Each component and its corresponding parts by weight are: 6 parts of traditional Chinese medicine extract, 0.2 part of sodium hydroxide, 90 parts of water;

[0031] (3) Drying treatment:

[0032] Put the bamboo weaving product processed in step (2) into a microwave drying oven for drying treatment, and take it out for later use after the water content of the bamboo weaving product is not more than 10%;

[0033] (4) Paint treatment:

[003...

Embodiment 2

[0043] A method for improving the anti-mildew and anti-aging characteristics of bamboo products, comprising the steps of:

[0044] (1) Polishing treatment:

[0045] Grinding and polishing the woven bamboo products for later use;

[0046] (2) Cooking treatment:

[0047] Put the bamboo woven product treated in step (1) into a pot filled with cooking liquid, heat to keep the temperature of the cooking liquid at 63°C, take it out after cooking for 22 minutes, and cool it down to room temperature naturally for later use; in the cooking liquid Each component and its corresponding parts by weight are: 8 parts of traditional Chinese medicine extract, 0.4 part of sodium hydroxide, and 95 parts of water;

[0048] (3) Drying treatment:

[0049] Put the bamboo weaving product treated in step (2) into a microwave drying oven for drying treatment, and take it out for later use after the water content of the bamboo weaving product is not more than 9%;

[0050] (4) Paint treatment:

[00...

Embodiment 3

[0060] A method for improving the anti-mildew and anti-aging characteristics of bamboo products, comprising the steps of:

[0061] (1) Polishing treatment:

[0062] Grinding and polishing the woven bamboo products for later use;

[0063] (2) Cooking treatment:

[0064] Put the bamboo woven product treated in step (1) into a pot filled with cooking liquid, heat to keep the temperature of the cooking liquid at 65°C, take it out after cooking for 25 minutes, and cool it down to room temperature naturally for later use; in the cooking liquid Each component and its corresponding parts by weight are: 10 parts of traditional Chinese medicine extract, 0.5 parts of sodium hydroxide, and 100 parts of water;

[0065] (3) Drying treatment:

[0066] Put the bamboo weaving product treated in step (2) into a microwave drying oven for drying treatment, and take it out for later use after the water content of the bamboo weaving product is not more than 8%;

[0067] (4) Paint treatment:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com