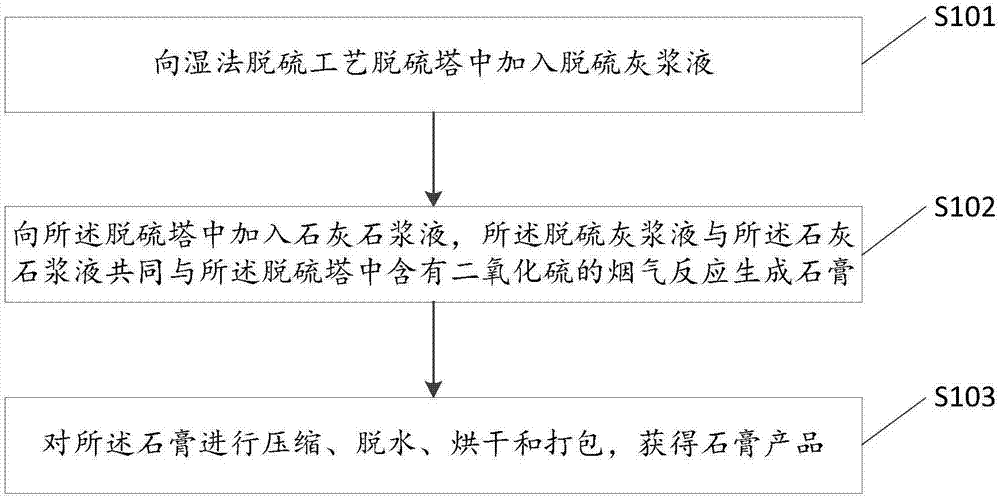

Method for utilizing semidry desulfurization ash in wet flue gas desulfurization process

A wet flue gas desulfurization and semi-dry desulfurization technology, applied in chemical instruments and methods, calcium/strontium/barium sulfate, inorganic chemistry, etc., can solve the problems of low added value and long transportation distance, and achieve improved The effect of side bonuses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

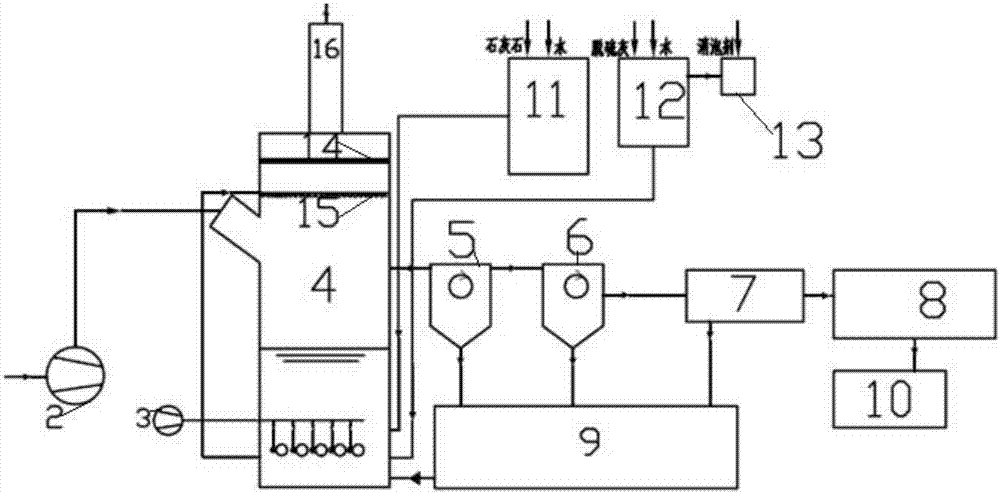

Method used

Image

Examples

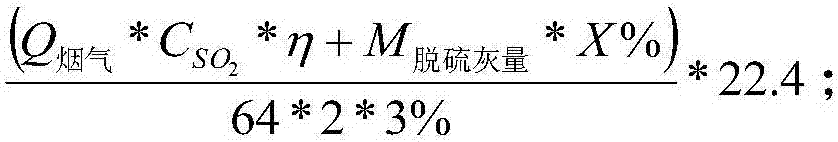

Embodiment 1

[0059] The desulfurization ash is obtained from the rotary spray semi-dry desulfurization process, and the main component is CaCO 3 Content 25.2%, CaSO 3 .2H 2 O content 34.9%, CaSO 4 Content 19.3% and Ca(OH) 2 The content is 20.1%, and the impurity content is 0.5%. CaCO in limestone 3 The content is 91.7%, and the particle size is less than 200 mesh. Put the desulfurized ash and limestone into the desulfurized ash slurry tank and the limestone slurry tank respectively according to the mass ratio of 0.3:1, and then add water to make desulfurized ash slurry and limestone slurry respectively. Specifically, the solid concentration of the desulfurized ash slurry and the limestone slurry is 15%. In addition, a 5% ethanol solution was added to the desulfurization ash pulping tank for defoaming. The prepared desulfurization ash slurry and limestone slurry are respectively input into the desulfurization tower and used as desulfurizers. Oxidation fan according to 2000m 3 / h Fi...

Embodiment 2

[0061] The desulfurization ash is taken from the semi-dry desulfurization process of the circulating fluidized bed, and the main component is CaCO 3 Content 23.2%, CaSO 3 .2H 2 O content 28.9%, CaSO 4 Content 26.3% and Ca(OH) 2 The content is 20.1%, and the impurity content is 1.5%. CaCO in limestone 3 The content is 92.7%, and the particle size is less than 200 mesh. Put the desulfurized ash and limestone into the desulfurized ash slurry tank and the limestone slurry tank respectively according to the mass ratio of 0.2:1, and then add water to make desulfurized ash slurry and limestone slurry respectively. Specifically, the slurry solids concentration was 12%. Add 5% ethanol solution to the desulfurization ash pulping tank for defoaming. The prepared desulfurization ash slurry and limestone slurry are respectively input into the desulfurization tower and used as desulfurizers. Oxidation fan according to 1900m 3 / h Fill the desulfurization tower with oxygen, on the on...

Embodiment 3

[0063] The desulfurization ash is obtained from the new integrated semi-dry desulfurization process, and the main component is CaCO 3 Content 25.2%, CaSO 3 .2H 2 O content 37.9%, CaSO 4 Content 7.9% and Ca(OH) 2 The content is 28.1%, and the impurity content is 0.9%. CaCO in limestone 3 The content is 94.7%, and the particle size is less than 200 mesh. Put the desulfurized ash and limestone powder into the desulfurized ash slurry tank and limestone slurry tank respectively according to the mass ratio of 0.5:1, and then add water to make desulfurized ash slurry and limestone slurry respectively. Specifically, the slurry solids concentration was 14%. A 3% methanol solution was added to the desulfurization ash pulping tank for defoaming. The prepared desulfurization ash slurry and limestone slurry are respectively input into the desulfurization tower and used as desulfurizers. Oxidation fan according to 2200m 3 / h Fill the desulfurization tower with oxygen, on the one ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com