River channel irrigation water purification system and method thereof

A technology for purifying system and irrigation water, applied in chemical instruments and methods, separation methods, multi-stage water treatment, etc., can solve the problems of easy blockage in the filtration process, large and complex structure, low purification efficiency, etc., and achieves a small footprint. , The effect of low backwash water consumption and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

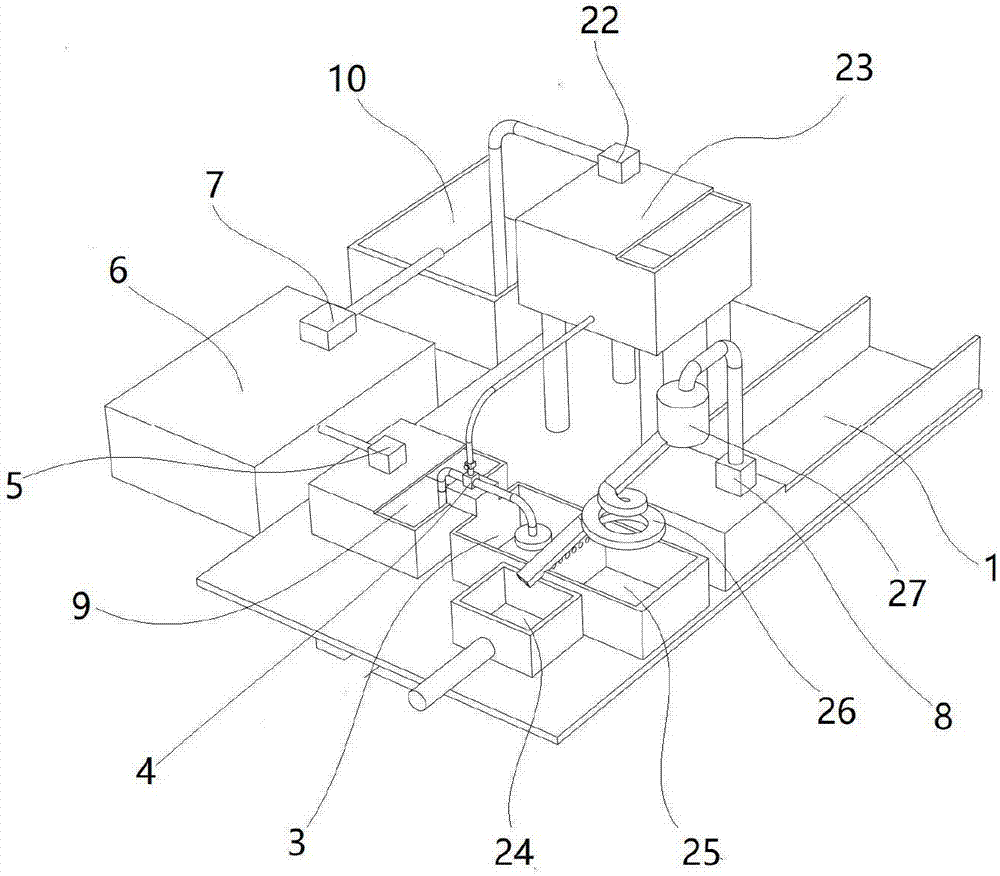

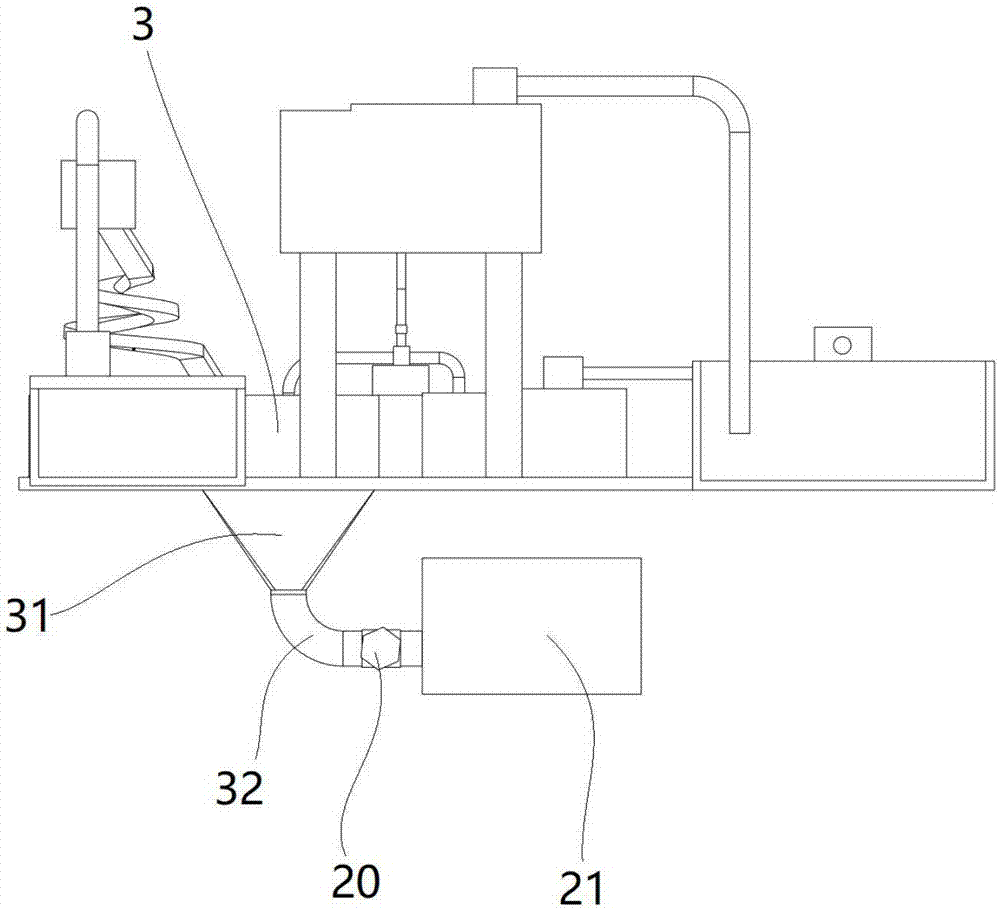

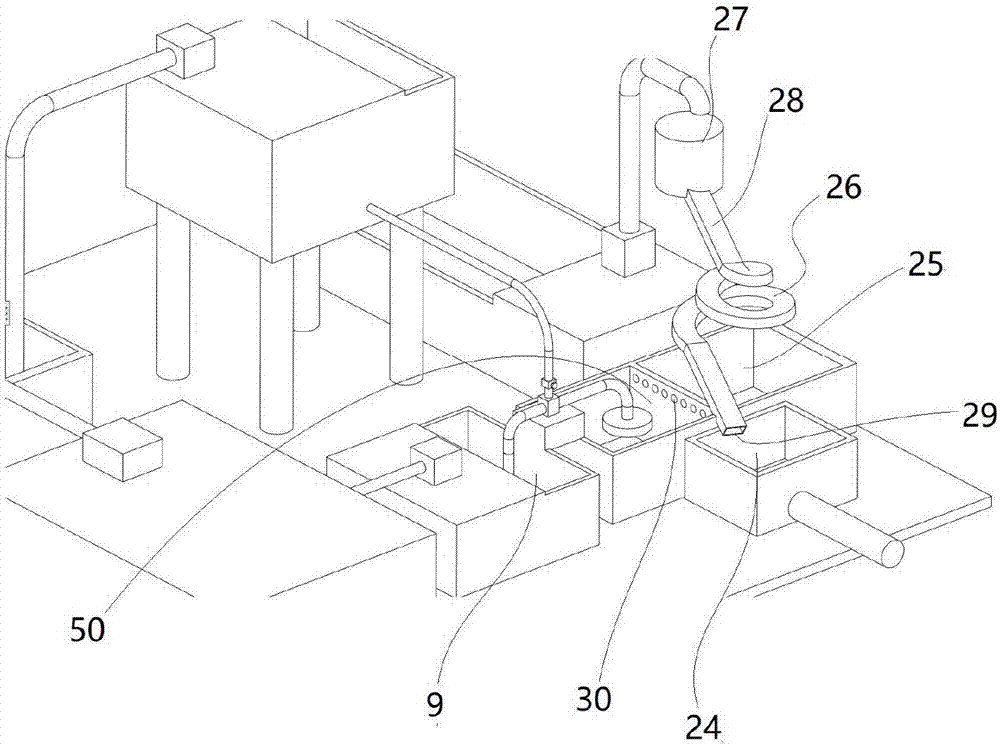

[0032] as attached Figures 1 to 3 As shown, a river irrigation water purification system includes source water channel 1, high water tank 27, water screener 26, water receiving tank 25, sundries receiving tank 24, pre-sedimentation tank 3, storage tank to be purified 9, not Symmetrical fiber filter 6, irrigation pond 10, first water pump 8, second water pump 5, third water pump 7 and siphon device 4;

[0033] Among them, the filter material of the asymmetric fiber filter 6 is asymmetric fiber. On the basis of the fiber bundle filter material, a core is added to make it have the advantages of both fiber filter material and particle filter material. Due to the special structure of the filter material, the The porosity of the filter bed quickly forms a gradient density with a large top and a small bottom, so that the filter has a fast filtration rate, a large sewage int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com