CrB2 coating layer with high hardness and corrosion resistance on surface of stainless steel substrate and preparation method thereof

A substrate surface, stainless steel technology, applied in metal material coating process, coating, ion implantation plating and other directions, can solve the problem of narrow phase interval, achieve dense structure, excellent wear and corrosion resistance, high hardness and the effect of compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

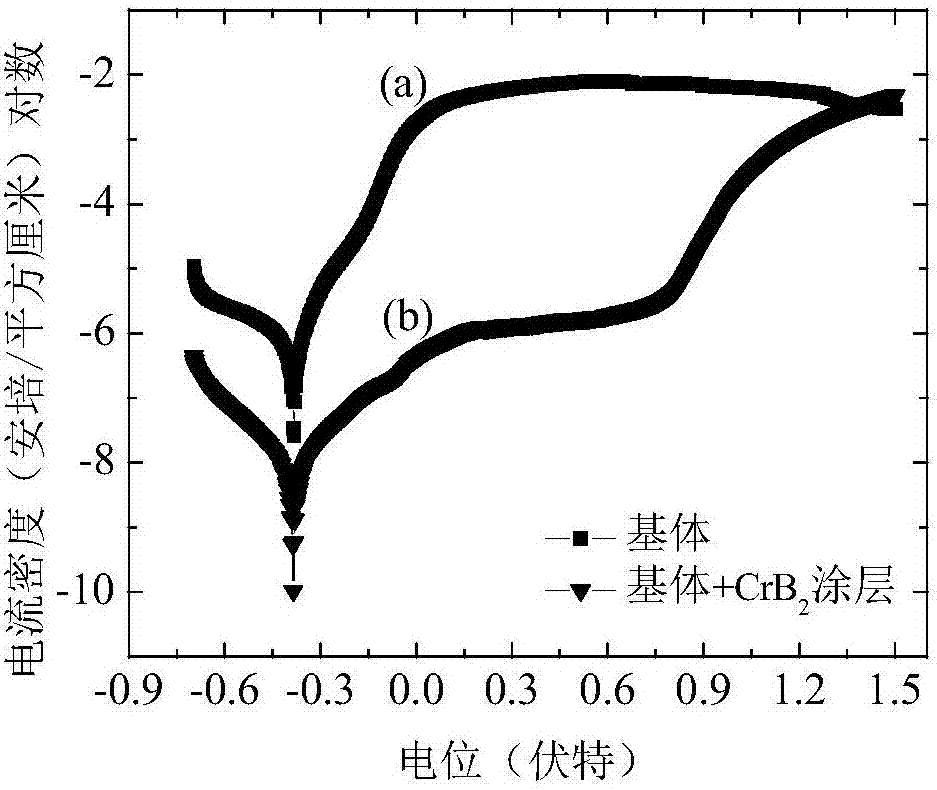

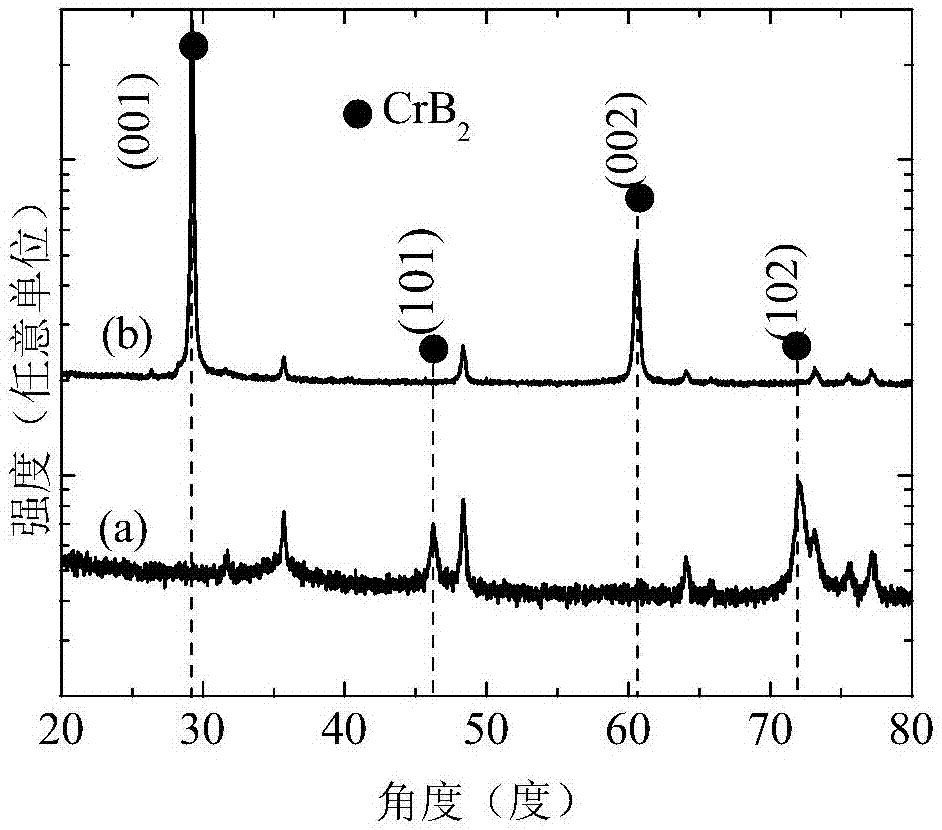

[0024] In this embodiment, the substrate is AISI 316L stainless steel. The protective coating on the surface of the substrate is CrB 2 The phase is the main phase structure.

[0025] The preparation method of above-mentioned protective coating is as follows:

[0026] The surface of the substrate is polished, decontaminated, ultrasonically cleaned with acetone and alcohol, and then placed in a vacuum chamber, and the coating is deposited by high-power pulse magnetron sputtering. Specifically, the substrate is facing the sputtering source in the vacuum chamber, and the target The base distance is 8cm; the Cr-B composite target is selected, in which the atomic ratio of Cr to B is 1:2, and argon gas is introduced as the working gas, and the flow rate of argon gas is 50 sccm; the cavity temperature is adjusted to 300°C, and the cavity pressure is 0.28Pa; high-power pulse sputtering power supply parameters are DC 1.8A, pulse voltage 650V, frequency 200Hz, pulse width 200μs; substr...

Embodiment 2

[0033] In this embodiment, the substrate is AISI 316L stainless steel. The protective coating on the surface of the substrate is CrB 2 The phase is the main phase structure.

[0034] The CrB on the surface of the substrate was prepared by high-power pulse magnetron sputtering method and DC magnetron sputtering method respectively. 2 coating, as follows:

[0035]The surface of the substrate was polished, decontaminated, ultrasonically cleaned with acetone and alcohol, and then placed in a vacuum chamber. The protective coating was deposited by high-power pulse magnetron sputtering and DC magnetron sputtering, specifically:

[0036] During the deposition process, the substrate is facing the sputtering source in the vacuum chamber, and the base distance of the target is 8cm; a Cr-B composite target is selected, in which the atomic ratio of Cr to B is 1:2, and argon gas is introduced as the working gas, and the flow rate of the argon gas is 50sccm; adjust the cavity temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com