Wheel hub electric motor and wheel hub electric motor system

A technology of in-wheel motor and driving wheel, which is applied to motor vehicles, electromechanical devices, electrical components, etc., can solve the problems of low coding accuracy, difficulty in meeting robots, and low motion control accuracy, and achieve the effect of improving accuracy and coding accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

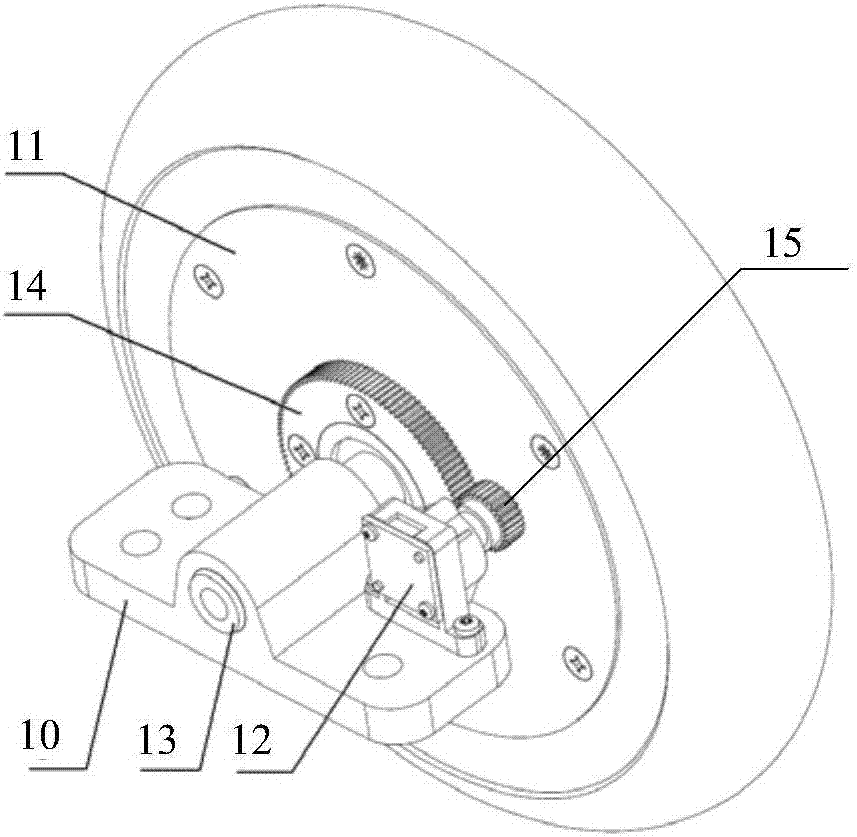

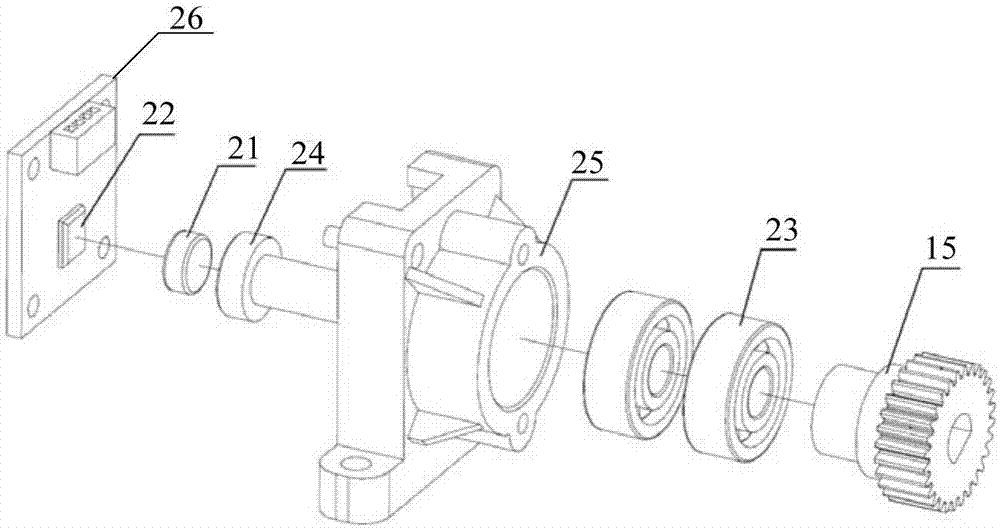

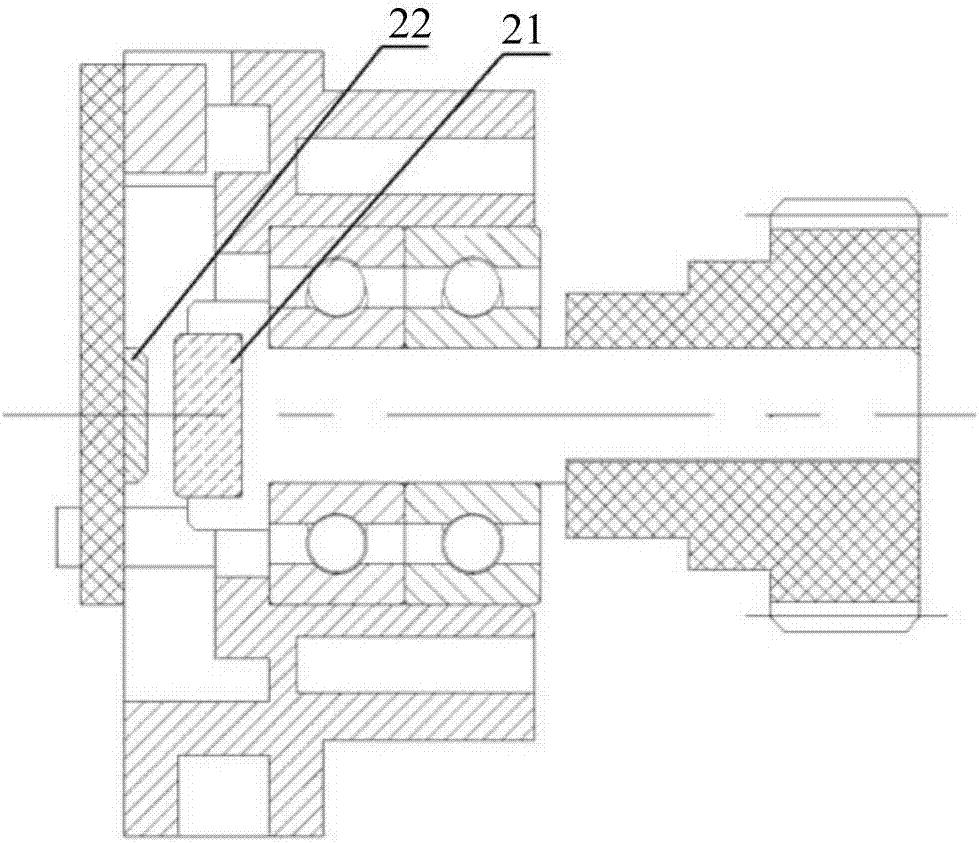

[0030] see figure 1 A structural schematic diagram of an in-wheel motor is shown; the in-wheel motor includes a fixing seat 10, a driving wheel 11 and an encoding module 12;

[0031] The driving wheel 11 is connected with the fixed seat 10 through the wheel shaft 13; the coding module 12 is fixedly arranged on the fixed seat 10; the driving wheel 11 is provided with a driving gear 14, and the driving gear 14 rotates synchronously with the driving wheel 11; the driving gear 14 and the coding module 12 The transmission gear 15 in the meshing connection; The diameter of driving gear 14 is greater than the diameter of transmission gear 15;

[0032] When the driving wheel 11 rotates, the driving gear 14 rotates synchronously; the driving gear 14 drives the transmission gear 15 to rotate, so that the encoding module 12 outputs an encoding signal.

[0033] For example, when the transmission gear rotates one revolution, the encoding module can output M encoding signals; since the dia...

Embodiment 2

[0062] Corresponding to the in-wheel motor provided in the first embodiment above, see Figure 5 A structural block diagram of an in-wheel motor system shown; the system includes the above-mentioned in-wheel motor 50, and also includes a central control module 51;

[0063] The central control module 50 is electrically connected to the driving wheel 11 and the encoding module 12 in the in-wheel motor; the central control module 50 is used to control the rotation of the driving wheel 11;

[0064] In an in-wheel motor system provided by an embodiment of the present invention, the driving gear on the driving wheel is meshed with the transmission gear in the encoding module, and the diameter of the driving gear is larger than the diameter of the transmission gear; when the driving wheel rotates, the driving gear drives the transmission gear Rotate to make the encoding module output the encoding signal; in this way, compared with the way that the encoding module is directly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com