Conveying device and tuber crop harvester with conveying device

A conveying device and rhizome technology, applied in the field of rhizome crop harvesters, can solve the problems of inability to separate root crops from soil, leaves and other sundries, achieve the convenience of continuous transportation and removal of soil and impurities, improve processing efficiency, The effect of enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

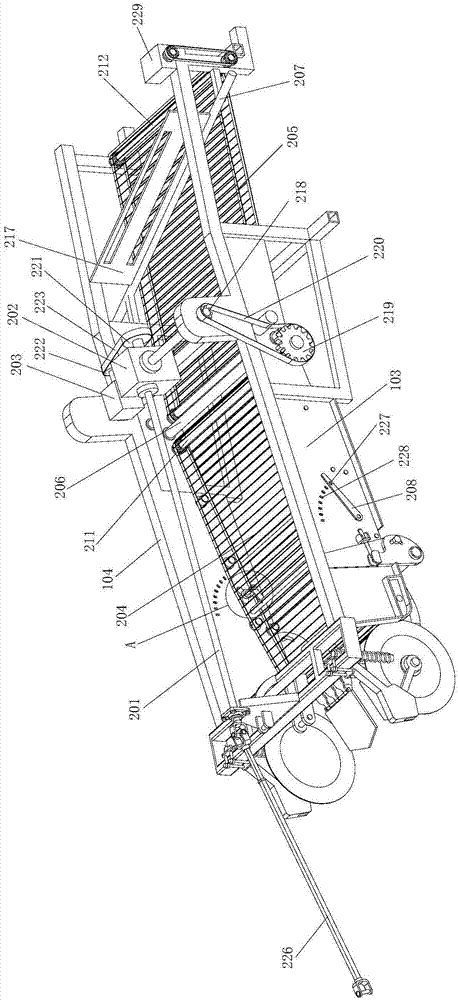

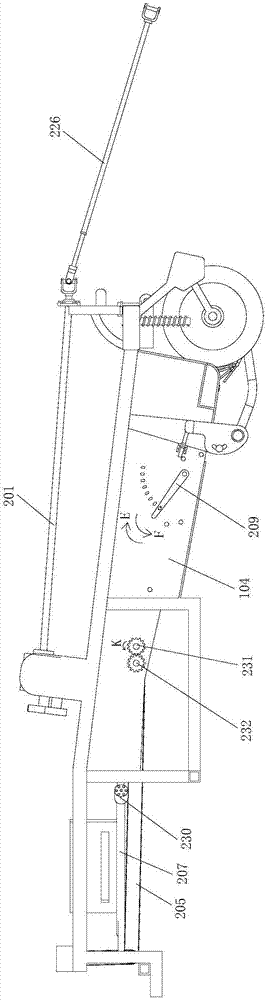

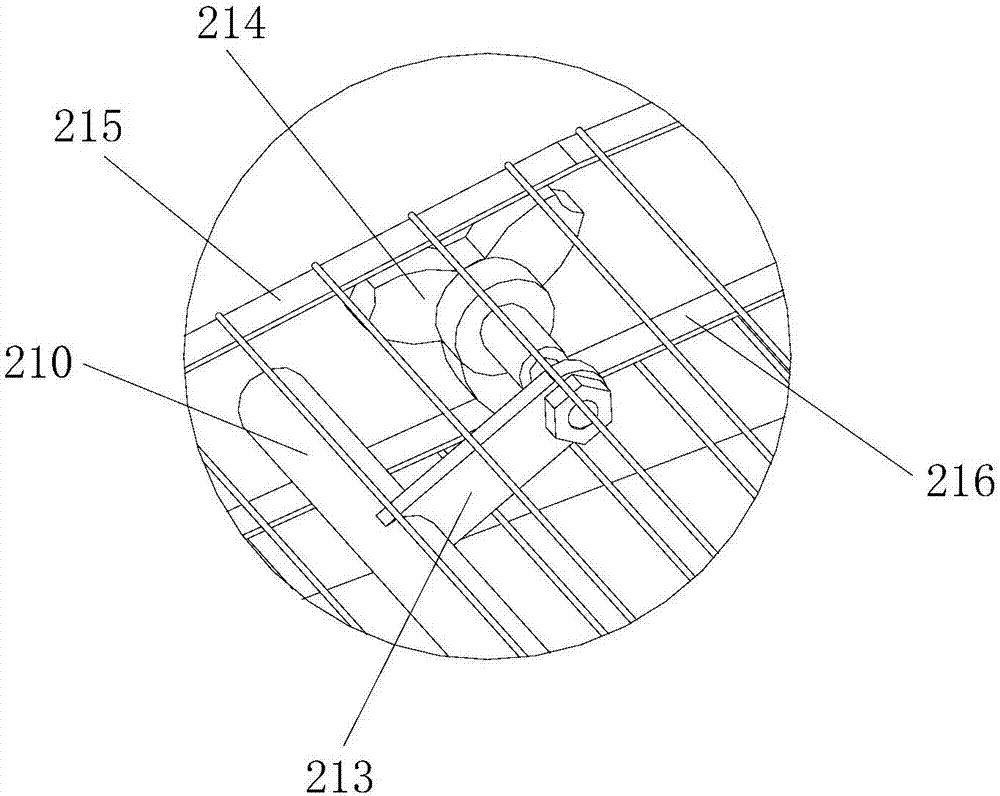

[0033] figure 1 It is a schematic structural diagram of the transmission device provided in Embodiment 1 of the present invention; figure 2 for figure 1 rear view of image 3 for figure 1 Partial enlarged view of A in the center. see Figure 1 to Figure 3 As shown, the present embodiment provides a conveying device, including a frame, and the frame is provided with a driving shaft 201, a gearbox 202, a hydraulic pump 203, a first chain conveying mechanism 204 and a second chain conveying mechanism 205; the driving shaft 201 One end of the drive shaft 201 is used to drive the output shaft of the traction device, preferably, one end of the drive shaft 201 is connected to the output shaft of the traction device through a coupling 226, and the other end of the drive shaft 201 is connected to the input shaft of the gearbox 202. , the first output shaft of the gearbox 202 is connected with the transmission of the first chain conveying mechanism 204, the first chain conveying m...

Embodiment 2

[0052] Figure 4 A schematic structural view of a harvester for rhizome crops provided in Embodiment 2 of the present invention; Figure 5 for Figure 4 Partial enlarged view of B in middle; Image 6 for Figure 4 Partial enlarged view at C in middle; Figure 7 A schematic diagram of the shovel positioned on the ground in the rhizome crop harvester provided by Embodiment 2 of the present invention; Figure 8 It is a schematic diagram of the shovel and the cutting knife in the rhizome harvester provided by Embodiment 2 of the present invention extending below the ground. Figure 4 Not shown in the shaft coupling 226, the first chain conveyor mechanism 204 and the second chain conveyor mechanism 205; Figure 8 In , the arrow direction D indicates the forward direction of the tractor driving the frame. In this embodiment, both the front end and the rear end are defined with reference to the forward direction. see Figure 4 to Figure 8 As shown, this embodiment provides a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com