Tunnel and stair step mopping robot

A robot and ladder technology, applied in the direction of robot cleaners, machine parts, manual floor scrubbing machinery, etc., to achieve the effect of cleaning the ground, improving work efficiency, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

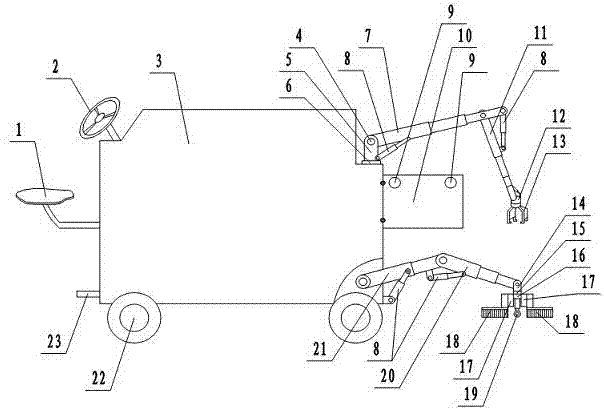

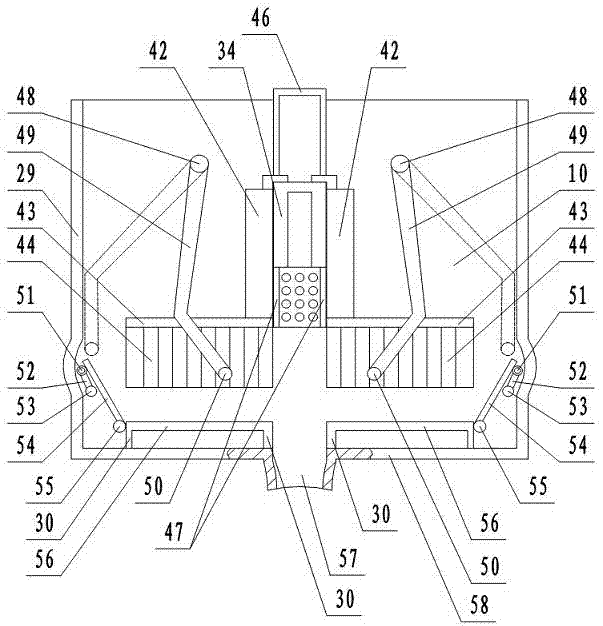

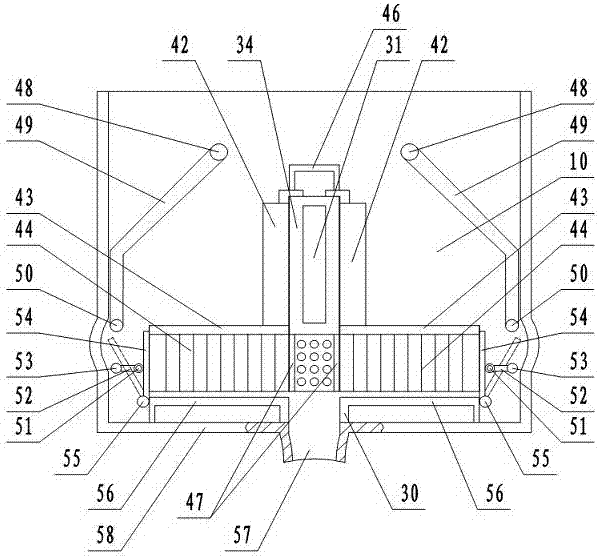

[0021] figure 1 In the figure, is the overall structure diagram of the tunnel and step mopping robot. A cleaning tank 10 is installed in the front of the car body 3, and a motor 9 is installed on the shell plate on one side of the cleaning tank. The cleaning tank is a rectangular shell. The clamping jaw clamping arm mechanism comprises a front clamping arm 11, a rear clamping arm 7, a hydraulic cylinder 8, a collet 12, and clamping jaws 13. Turntable 6 is installed on car body 3 front top. The hinge base 5 is installed on the turntable 6 . The rear end of the rear clip arm 7 is connected with the hinge seat 5 with the pivot pin 4 . The front clamp arm 11 rear end is hinged with the rear clamp arm 7 front ends. A hydraulic cylinder 8 is installed between the rear clamp arm rear end and the turntable, between the front clamp arm rear section and the rear clamp arm. The front and rear clamp arms are multi-section telescopic arm structures. A chuck 12 is connected to the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com