A scr denitration device

A technology of denitrification and rectification device, which is applied in the field of flue gas purification, can solve the problems of reduced denitrification efficiency, long distance between reducing agent and flue gas, uneven mixing of reducing agent and flue gas, etc., to achieve the effect of improving uniformity and preventing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

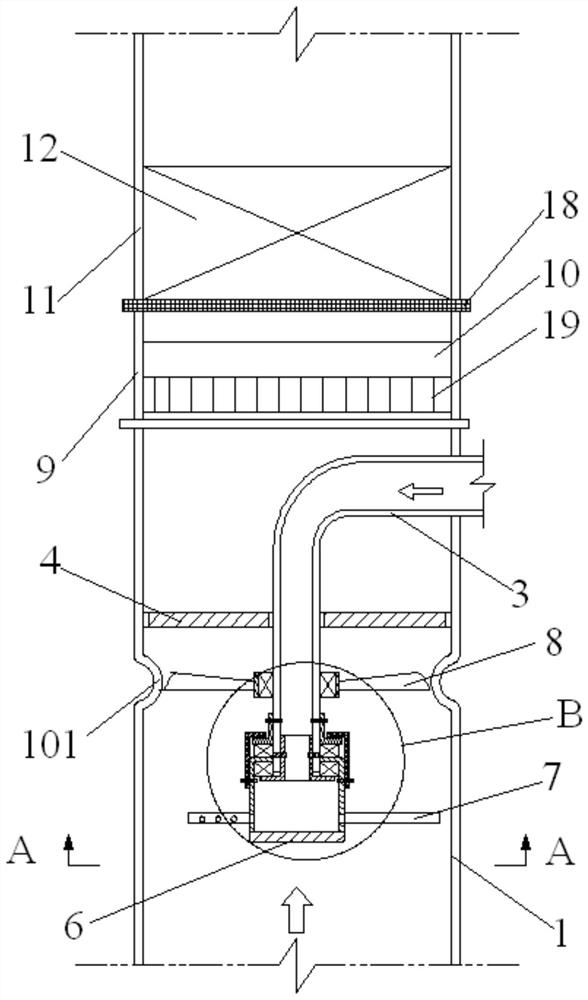

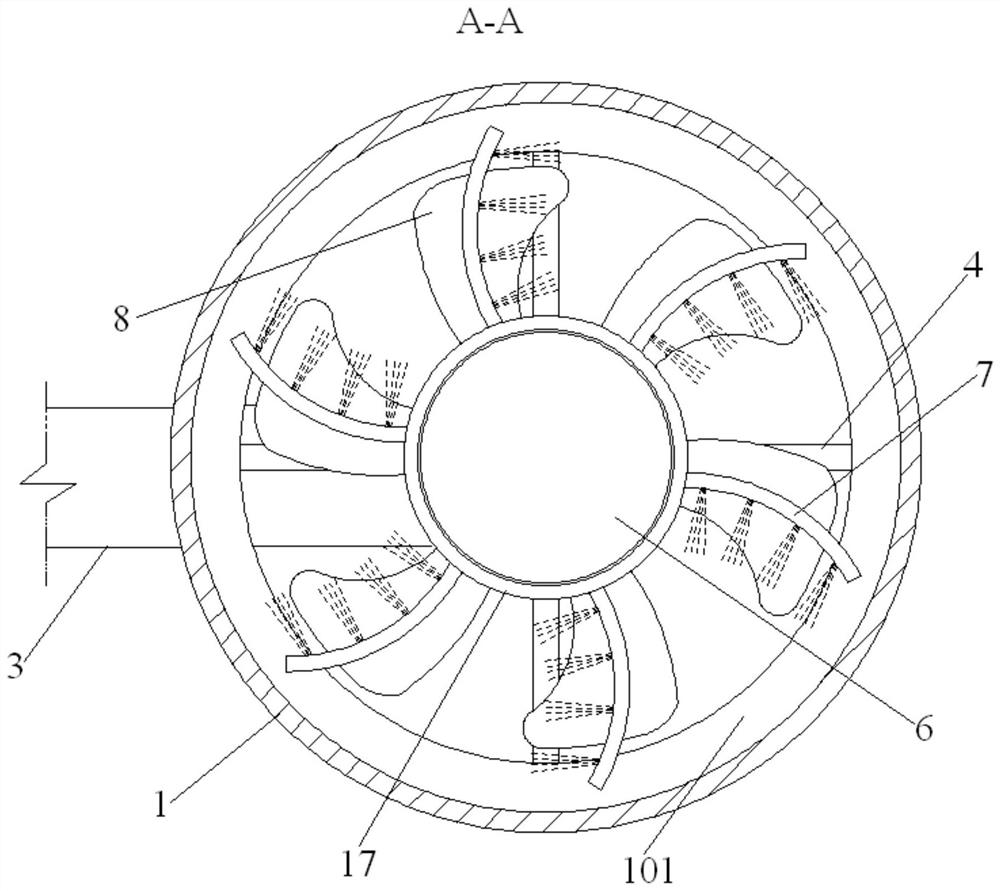

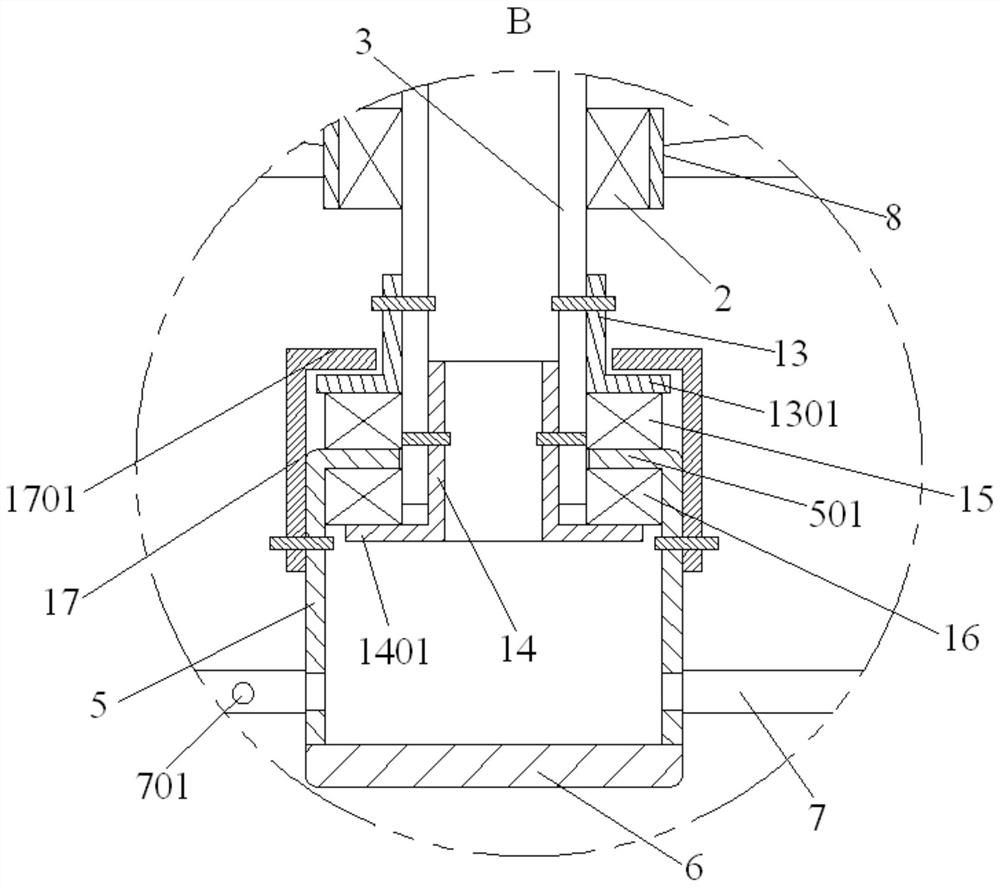

[0026] refer to Figure 1 to Figure 3, the embodiment of the present invention proposes a kind of SCR denitrification device, is used for carrying out denitrification treatment to flue gas, comprises: intake mixing section 1, rotary drum 5, wind impeller 8, rectifying section 9 and catalytic section 11; 1 is connected with the flue gas discharge pipeline 2, and the air intake mixing section 1 is provided with a reducing agent supply pipe 3 and a fixing frame 4, and the outlet end of the reducing agent supply pipe 3 is fixed on the fixing frame 4, and the reducing agent supply pipe 3 The inlet end of the intake port passes out of the side wall of the intake mixing section 1; the rotary drum 5 is rotated and assembled on the port of the outlet end of the reducing agent supply pipe 3, and the rotary drum 5 communicates with the reducing agent supply pipe 3, and the rotary drum 5 The other end is connected with an end cover 6, and the side wall of the drum 5 is connected with a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com