A method for preparing magnetic adsorbent by using waste zinc-manganese batteries and biomass

A magnetic adsorbent, zinc-manganese battery technology, applied in chemical instruments and methods, adsorption of water/sewage treatment, water pollutants, etc., can solve the problem of high production cost and process requirements, difficult powder agglomeration, equipment materials and safety High requirements and other issues, to achieve the effect of high value-added resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Step 1. Take the electrode material of the waste zinc-manganese battery, grind the battery electrode material into powder and pass it through a sieve to obtain electrode powder with a particle size of less than 125 μm;

[0046] Step 2, with sulfur powder and ferrous sulfate as the mixed energy substrate, the mixed volume ratio is 1:1:1 Thiobacillus thiooxidans bacteria liquid, Leptospira ferrous oxide bacteria liquid and Thiobacillus ferrooxidans bacteria The mixture was mixed to form a mixed leaching strain, and the mixed leaching strain was regularly inoculated and cultivated for 5 days in a shaker with a rotation speed of 150r / min and a temperature of 35°C with a mixed energy substrate and nutrient salts, and then centrifuged, After filtering, the biological extract is obtained;

[0047] During the inoculation process:

[0048] The solvent of nutrient salt is water, and the solute of nutrient salt is: (NH 4 ) 2 SO 4 , KH with a content of 1.0g / L 2 PO 4 , MgSO w...

Embodiment 2

[0056] Step 1. Take the electrode material of the waste zinc-manganese battery, grind the battery electrode material into powder and pass it through a sieve to obtain electrode powder with a particle size of less than 125 μm;

[0057] Step 2, with sulfur powder and ferrous sulfate as the mixed energy substrate, the mixed volume ratio is 1:1:1 Thiobacillus thiooxidans bacteria liquid, Leptospira ferrous oxide bacteria liquid and Thiobacillus ferrooxidans bacteria The mixture was mixed to form a mixed leaching strain, and the mixed leaching strain was regularly inoculated and cultivated for 3 days in a shaker with a rotation speed of 160r / min and a temperature of 40°C with mixed energy substrates and nutrient salts, and then centrifuged, After filtering, the biological extract is obtained;

[0058] During the inoculation process:

[0059] The solvent of nutrient salt is water, and the solute of nutrient salt is: (NH 4 ) 2 SO 4 , KH with a content of 1.0g / L 2 PO 4 , MgSO wi...

Embodiment 3

[0067] Step 1. Take the electrode material of the waste zinc-manganese battery, grind the battery electrode material into powder and pass it through a sieve to obtain electrode powder with a particle size of less than 125 μm;

[0068] Step 2, with sulfur powder and ferrous sulfate as the mixed energy substrate, the mixed volume ratio is 1:1:1 Thiobacillus thiooxidans bacteria liquid, Leptospira ferrous oxide bacteria liquid and Thiobacillus ferrooxidans bacteria The mixture was mixed to form a mixed leaching strain, and the mixed leaching strain was regularly inoculated and cultivated for 5 days in a shaker with a rotation speed of 130r / min and a temperature of 30°C with mixed energy substrates and nutrient salts, and then centrifuged, After filtering, the biological extract is obtained;

[0069] During the inoculation process:

[0070] The solvent of nutrient salt is water, and the solute of nutrient salt is: (NH 4 ) 2 SO 4 , KH with a content of 1.0g / L 2 PO 4 , MgSO wi...

PUM

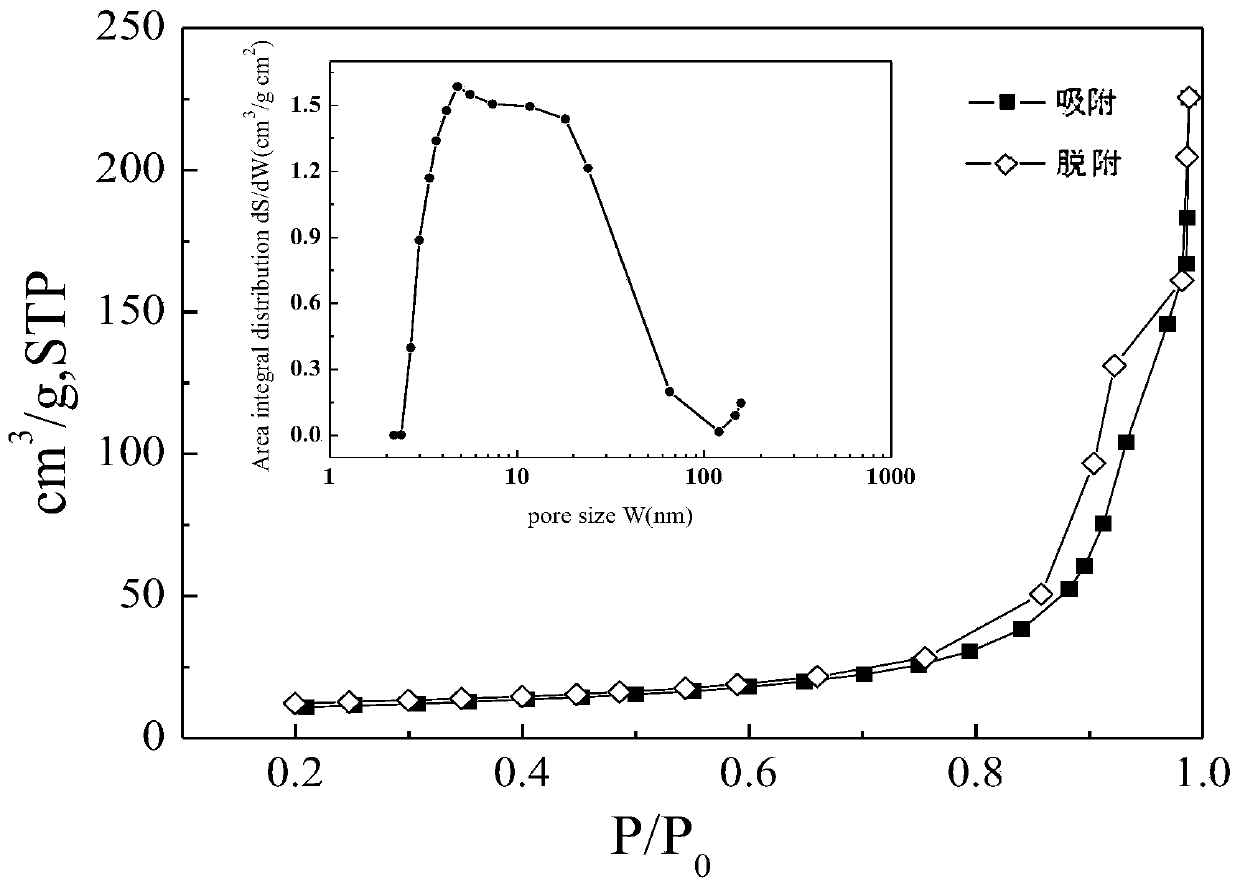

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com