Aluminum oxide crust block air-swept autogenous mill capable of recycling aluminum slag online

An autogenous mill, alumina technology, applied in the improvement of process efficiency, grain processing and other directions, can solve the problems of high labor intensity, operator safety, low efficiency, etc., and achieve the effect of avoiding long downtime and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to facilitate the understanding of the technical means, creative features and goals achieved by the present invention, the present invention will be further elaborated below in conjunction with specific schematic diagrams, but the scope of protection claimed by the present invention is not limited to the scope described in the specific embodiments.

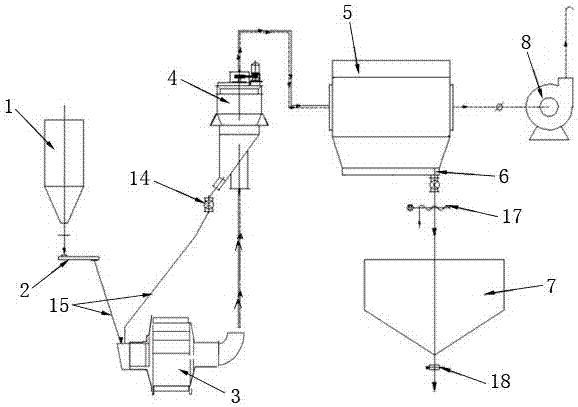

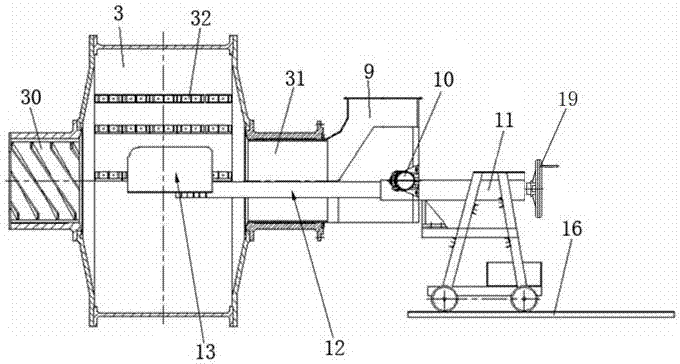

[0015] An air-swept autogenous mill capable of recycling aluminum slag on-line, such as figure 1 As shown, the mill system includes a buffer bin 1, a feeder 2, an autogenous mill 3, a sorter 4, a bag filter 5, a screw conveyor 6, and a finished product bin 7, which are sequentially connected through a pipeline 15. 3. The discharge ends of the sorting machine 4 and the bag filter 5 are all connected to the fan 8, and the fan 8 provides the system with negative pressure for extracting materials. The qualified particles selected by the sorter 4 pass through the bag filter 5 and enter the finished product warehouse 7 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com