Laminated continuous extrusion metal tube mosquito coil production line and production method

A layered, fragrant coiled tube technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc. Pipe scratches and other problems, to achieve the effect of easy automatic control, high production efficiency, and reduced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

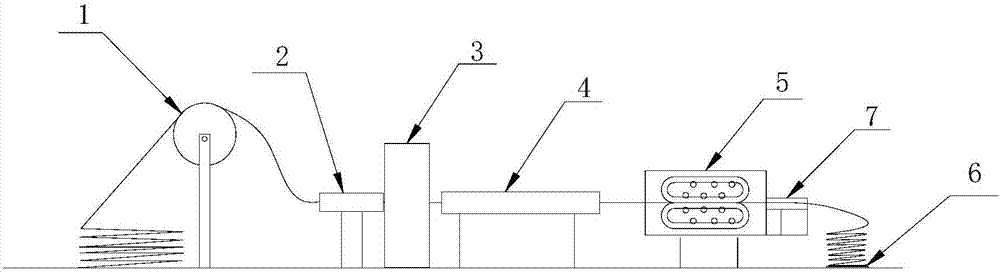

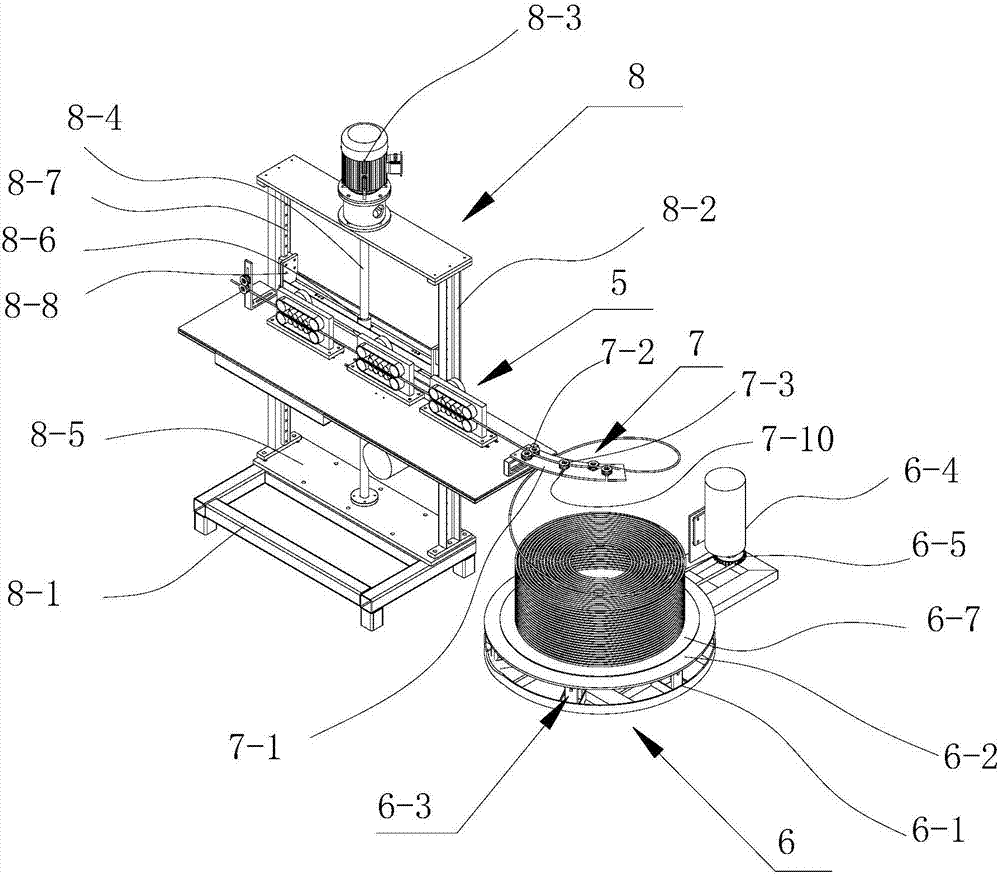

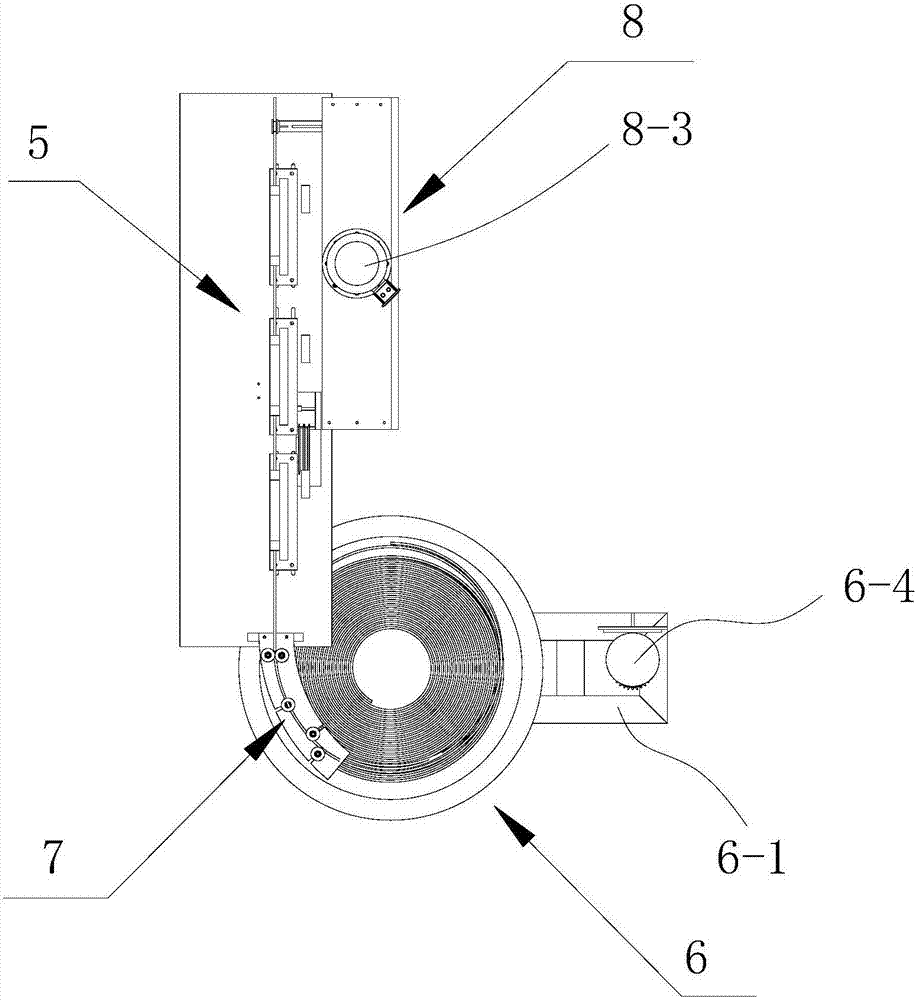

[0039] Example 1, see Figure 1 to Figure 4 , a laminated continuous extrusion metal tube mosquito coil production line, which sequentially includes an aluminum rod cutting device 1, an aluminum rod cleaning device 2, an aluminum tube extrusion machine 3, an aluminum tube cooling treatment device 4, an aluminum tube traction device 5, The forming aluminum tube coiling device 6, the above-mentioned aluminum rod cutting device 1, aluminum rod cleaning device 2, aluminum tube extrusion machine 3, aluminum tube cooling treatment device 4, and aluminum tube traction device 5 belong to mature technologies in aluminum tube production. This will not be described in detail; the aluminum tube pulling device 5 is provided with a forming aluminum tube bending mechanism 7 that tends to bend the formed aluminum tube according to a certain bending radius; the forming aluminum tube bending mechanism 7 is installed on the aluminum tube pulling device 5 The discharge end of the forming aluminum...

Embodiment 2

[0043] Example 2, see Figure 5 In this embodiment, the lifting device 8 is installed on the formed aluminum tube coiling device 6; it includes a base 8-10, a bearing platform 8-20 and a drive cylinder 8-30, and a hinged support rod 8-40 between the base and the bearing platform , one end of the drive cylinder is hingedly mounted on the base, and the other end of the drive cylinder is hinged on the lower surface of the bearing platform 8-20, and other features are the same as those in Embodiment 1.

Embodiment 3

[0044] Example 3, see Figure 6 , in order to realize the continuous coil operation, it also includes a bending and swinging mechanism 12 for changing the output angle of the forming aluminum tube bending mechanism. For driving oil cylinder, air cylinder or servo motor, all the other are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com