Special feeding and blanking device for numerical control machine tool

A numerical control machine tool and quantity technology, applied in the field of numerical control machine tools, can solve the problems of inability to purchase a machine tool loading and unloading device, difficult to disassemble and remove, troublesome installation, etc., and achieve the effects of simple structure, good practicability and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

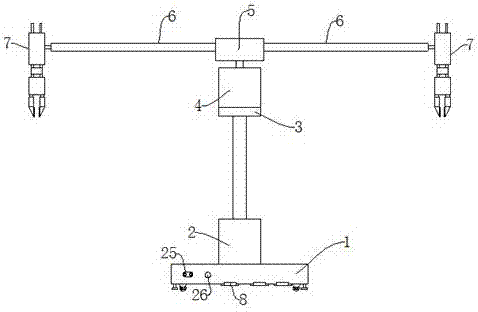

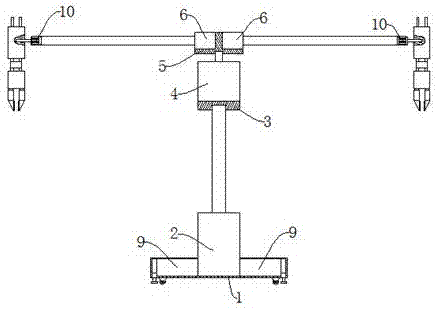

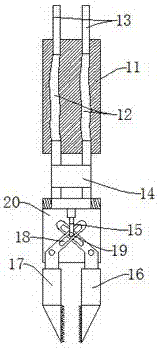

[0018] Such as Figure 1-Figure 4 As shown, a special loading and unloading device for CNC machine tools, including a base 1, the upper end of the base 1 is provided with a first electro-hydraulic push rod 2, and the first electro-hydraulic push rod 2 is used to push the pneumatic manipulator 7 to move up and down, Adjust the height of the pneumatic manipulator 7 from the ground, the upper end of the first electrohydraulic push rod 2 is provided with a first stepping motor 4, and the first stepping motor 4 is used to drive the pneumatic manipulator 7 around the first An electro-hydraulic push rod 2 rotates, the upper end of the first stepping motor 4 is provided with a second electro-hydraulic push rod 6, and the second electro-hydraulic push rod 6 is used to drive the pneumatic manipulator 7 along the mounting base 5 left and right Move, adjust the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com