Shoe sole/shoe vamp polishing manipulator capable of automatically adjusting polishing strength and angle

An automatic adjustment and manipulator technology, applied in the direction of manipulators, shoemaking machinery, grinding/polishing equipment, etc., can solve the problems of grinding head loss, inconvenient control of grinding angle and grinding force, and increase of production cost, so as to achieve precise grinding , Conducive to production application, improve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

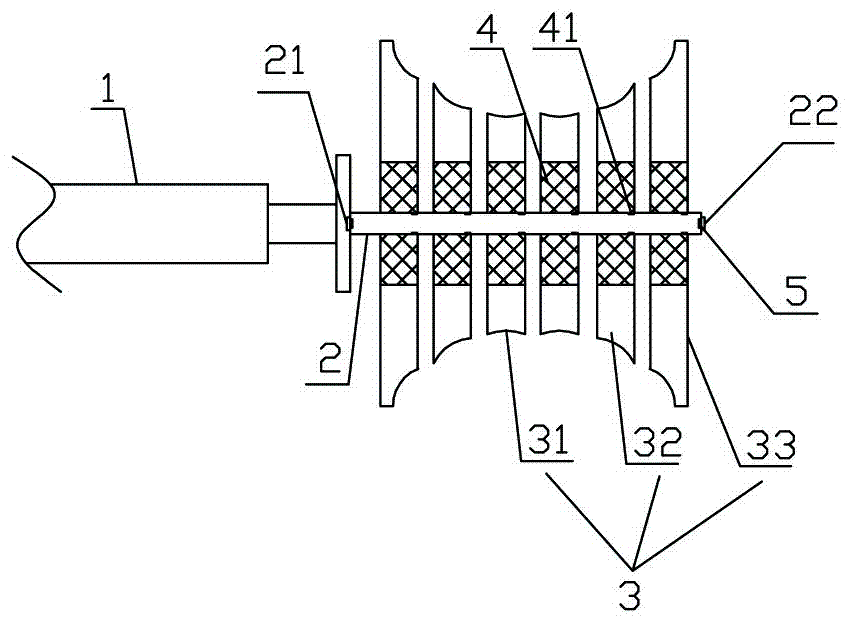

[0020] Such as figure 1 As shown, the sole / upper grinding manipulator that can automatically adjust the grinding strength and angle includes a mechanical arm 1 for grinding shoe soles, a grinding head mounting plate 2 arranged on the mechanical arm 1 and a motor that drives the mechanical arm 1 to move. The driving device (not shown in the figure due to the angle of view), the inside of the grinding head mounting plate 2 is a hollow closed cavity structure, and the grinding head mounting plate 2 is provided with an air inlet 21 and an air outlet 22, And on both sides of the grinding head mounting plate 2, several grinding heads 3 with different grinding angles are respectively installed, and a polishing airbag pad 4 is also arranged with a fixed pad between the grinding head 3 and the grinding head mounting plate 2, and The grinding airbag cushion 4 is communicated with the cavity of the grinding head mounting plate 2; the air inlet 21 and the air outlet 22 are respectively co...

Embodiment 2

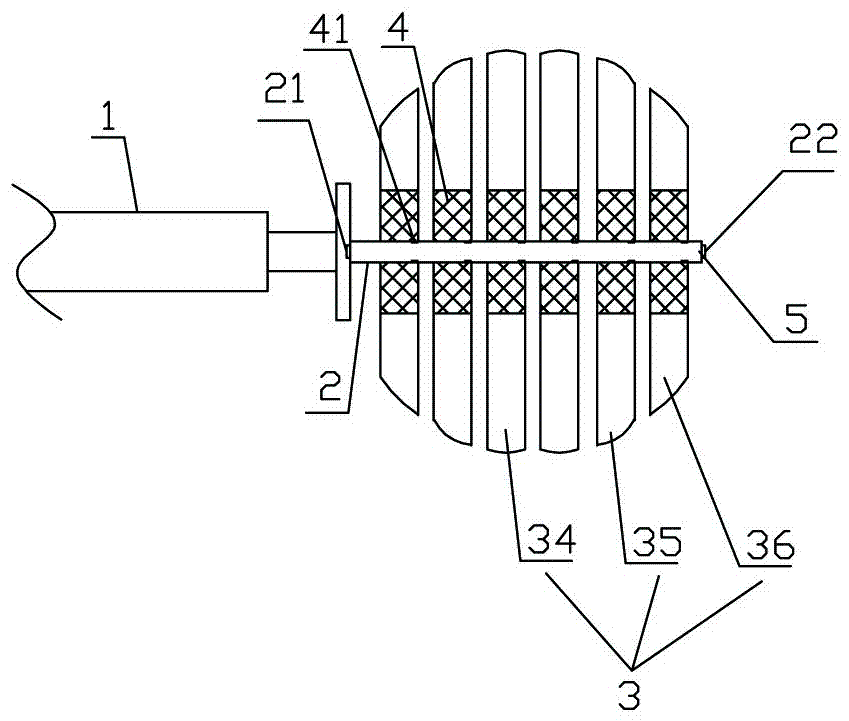

[0029] Such as figure 2 As shown, the sole / upper grinding manipulator that can automatically adjust the grinding strength and angle includes a mechanical arm 1 for grinding shoe soles, a grinding head mounting plate 2 arranged on the mechanical arm 1 and a motor that drives the mechanical arm 1 to move. The driving device (not shown in the figure due to the angle of view), the inside of the grinding head mounting plate 2 is a hollow closed cavity structure, and the grinding head mounting plate 2 is provided with an air inlet 21 and an air outlet 22, And on both sides of the grinding head mounting plate 2, several grinding heads 3 with different grinding angles are respectively installed, and a polishing airbag pad 4 is also arranged with a fixed pad between the grinding head 3 and the grinding head mounting plate 2, and The grinding airbag cushion 4 is communicated with the cavity of the grinding head mounting plate 2; the air inlet 21 and the air outlet 22 are respectively c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com