TPO self-adhesive water-proof coiled material

A technology of self-adhesive waterproof membrane and waterproof membrane, which is applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of not being able to realize double-layer waterproofing, and achieve self-healing, shortening Construction period, strong effect of crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

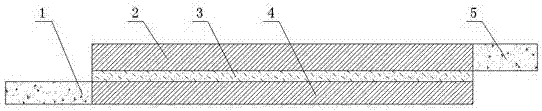

[0010] This embodiment is a TPO self-adhesive waterproof roll, see figure 1 , This waterproof membrane is composed of TPO layer 2, isolation film layer 3, and self-adhesive waterproof membrane layer 4, and the three-layer layered structure is composited into an integral membrane.

[0011] The integral coil is provided with adhesive edges, which are respectively: the TPO layer adhesive edge 5 provided on the TPO layer 2 as a whole, and the self-adhesive layer adhesive layer integrated with the self-adhesive waterproof coil layer 4. Bonding edge 1, TPO layer bonding edge 5 is opposite to the setting direction of self-adhesive layer bonding edge 1, and the lower part of TPO layer 2 with TPO layer bonding edge 5 is attached with an isolation film layer 3 with an oil-repelling effect, with a thickness of 0.7 ~2.0mm. It forms a layer of waterproof membrane with independent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com