Quick-drying type wall crack repair agent and preparation method thereof

A repairing agent and quick-drying technology, which is applied in the field of quick-drying wall crack repairing agent and its preparation, can solve the problems of time-consuming and material resources, labor and time-consuming, construction waste and noise pollution, etc., to save time, Low cost, simple and reliable construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention also provides a preparation method of a quick-drying wall surface crack repair agent, which is characterized in that it comprises the following steps:

[0025] a) Pour glutinous rice flour into water and stir into a paste to obtain a mixture;

[0026] b) adding gypsum, titanium dioxide, talcum powder, double fly powder, lime calcium to the mixture obtained in step a), and stirring evenly to obtain a paste;

[0027] c) Put the paste obtained in step b) into a bottle, and seal it for storage to obtain a quick-drying repairing agent for cracks on the wall.

[0028] Here, gypsum, titanium dioxide, talcum powder, Shuangfei powder, lime calcium, water, and glutinous rice flour are all the same as above, and will not be repeated here.

[0029] The quick-drying wall surface crack repair agent prepared by the above technical scheme has good affinity with the wall surface, is non-toxic, tasteless, green and environmentally friendly, has simple and reliable ...

Embodiment 1

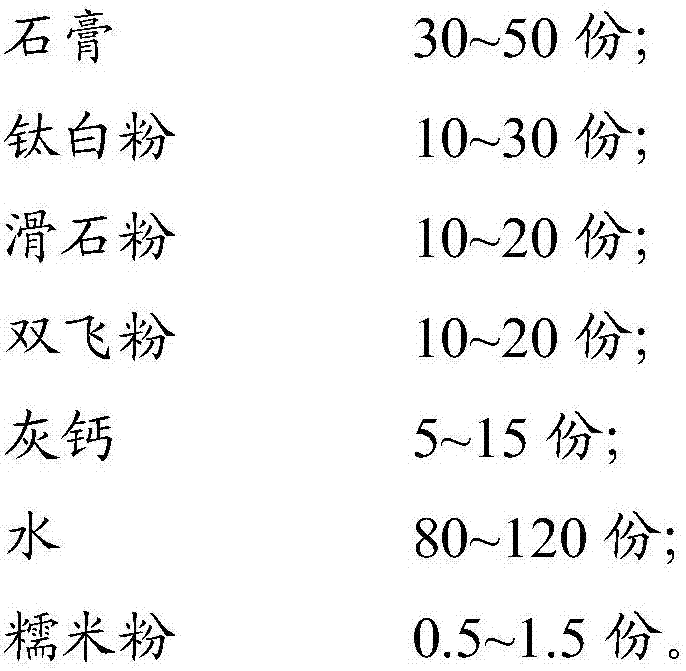

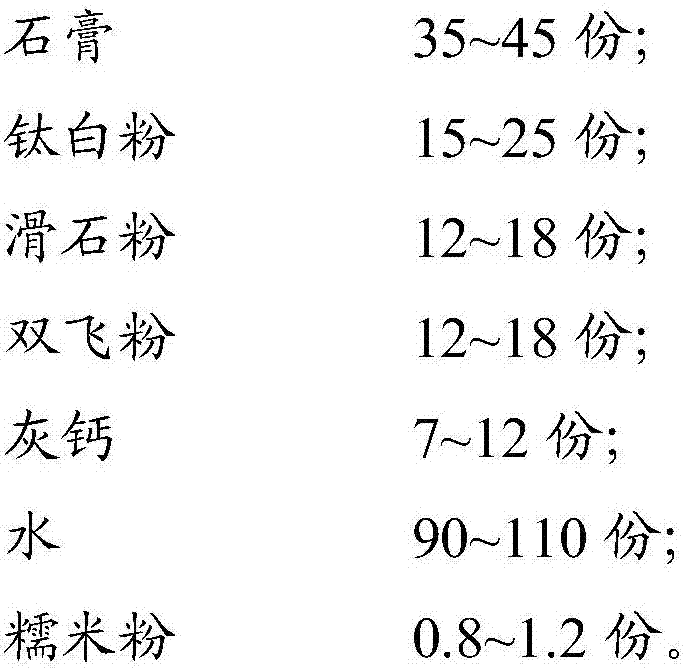

[0033] Include the raw material of following parts by weight in quick-drying type wall surface crack repairing agent:

[0034] 38 parts of gypsum, 15 parts of titanium dioxide, 18 parts of talcum powder, 13 parts of Shuangfei powder, 11 parts of ash calcium, 105 parts of water, 0.5 part of glutinous rice flour;

[0035] The preparation method of quick-drying type wall surface crack repairing agent is characterized in that, comprises the following steps:

[0036] a) Pour glutinous rice flour into water and stir into a paste to obtain a mixture;

[0037] b) adding gypsum, titanium dioxide, talcum powder, double fly powder, lime calcium to the mixture obtained in step a), and stirring evenly to obtain a paste;

[0038] c) Put the paste obtained in step b) into a bottle, and seal it for storage to obtain a quick-drying repairing agent for cracks on the wall.

Embodiment 2

[0040] Include the raw material of following parts by weight in quick-drying type wall surface crack repairing agent:

[0041] 43 parts of gypsum, 22 parts of titanium dioxide, 12 parts of talcum powder, 17 parts of Shuangfei powder, 8 parts of ash calcium, 95 parts of water, 0.8 parts of glutinous rice flour;

[0042] The preparation method of quick-drying type wall surface crack repairing agent is characterized in that, comprises the following steps:

[0043] a) Pour glutinous rice flour into water and stir into a paste to obtain a mixture;

[0044] b) adding gypsum, titanium dioxide, talcum powder, double fly powder, lime calcium to the mixture obtained in step a), and stirring evenly to obtain a paste;

[0045] c) Put the paste obtained in step b) into a bottle, and seal it for storage to obtain a quick-drying repairing agent for cracks on the wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com