A fully automatic diamond cobalt plating machine

A diamond, fully automatic technology, used in plating tanks, cells, electrolytic components, etc., can solve the problems of long cycle, inconvenient adjustment, and easy wear of plating tanks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

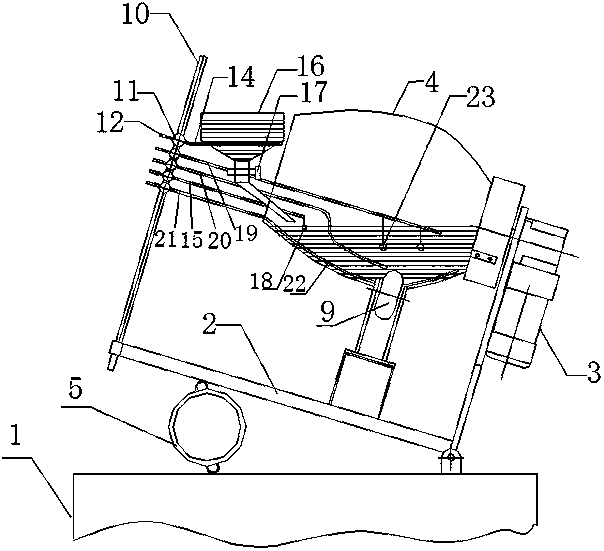

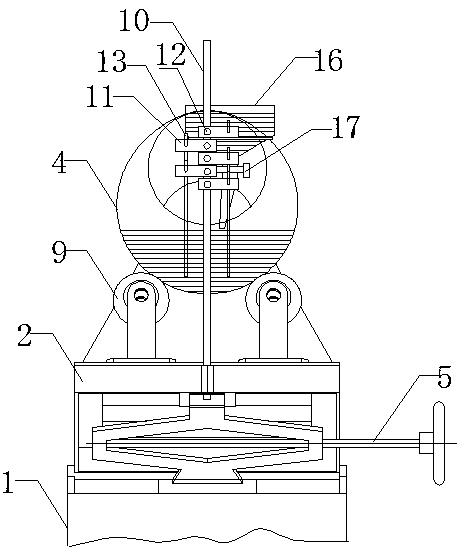

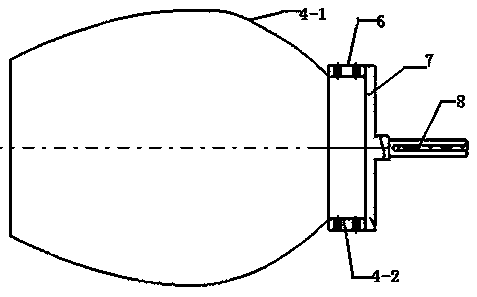

[0033]The device mainly includes a base 1, a cobalt-plating cylinder stirring mechanism, a cobalt-plating cylinder lifting mechanism, a detachable mounting bracket, a temperature control system, an electrode reaction system and a liquid level control system. The base 1 is used to support the whole device and plays a stable role; the cobalt-plating cylinder stirring mechanism mainly drives the cobalt-plating cylinder 4 to rotate through the servo motor 3, and uses a pair of support wheels 9 to support and slide at the same time, and the cobalt-plating cylinder 4 An opening is set at one end, which is convenient for feeding liquid, collecting some data information, and setting up some experimental equipment. The cobalt-plating barrel lifting mechanism is mainly used to tilt the cobalt-plating barrel stirring mechanism on one side, so that the cobalt-plating barrel 4 adjusts the inclination angle of the entire cobalt-plating barrel 4 according to the liquid level, thereby meeting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com