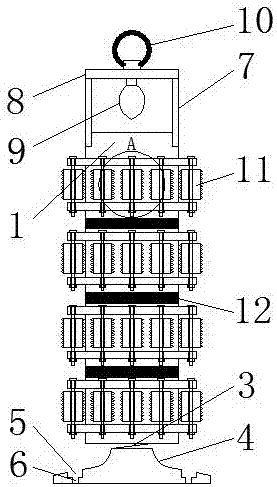

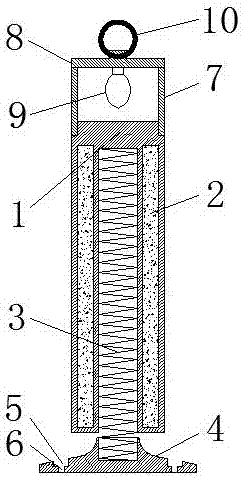

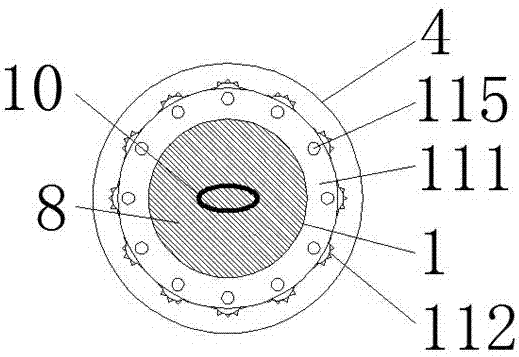

Fluorescent traffic warning pile

A warning post and traffic technology, applied in traffic signals, roads, road signs, etc., can solve the problems of easy bending, breaking and deformation of warning posts, and achieve the effects of avoiding wear, good fluorescent brightness, and enhanced buffering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] According to the chemical formula TS-1 / Zn-Yb 5.5 Nb 6.5 V 3 o 17 The stoichiometric ratio of each element, according to the molar ratio Yb ion: Nb ion: V ion is 5.5:6.5:5

[0023] Respectively weigh ytterbium oxide Yb 2 o 3 , Nb(OH) 5 , Vanadium pentoxide V 2 o 5 , after grinding and mixing uniformly in an agate mortar, select the air atmosphere to pre-calcine at 420°C for 10 hours in a muffle furnace, then cool to room temperature, take out the sample, mix the mixture thoroughly again, and grind it evenly in the air atmosphere , calcined at 1050°C for 2 hours, cooled to room temperature, taken out and fully ground to obtain Yb 5.5 Nb 6.5 V 3 o 17 powder,

[0024] Take 5 copies of Yb 5.5 Nb 6.5 V 3 o 17 Add the powder to 5% nitric acid, and add 2 parts of TS-1 powder and 0.5 part of Zn powder,

[0025] After stirring for one hour, filter and wash repeatedly, and finally calcine in the air atmosphere at 1300°C for 3 hours, cool to room temperature, take ...

Embodiment 2

[0028] Yb 3 Nb 7 V 3 o17 The stoichiometric ratio of each element, according to the molar ratio Yb ion: Nb ion: V ion is 3:7:3

[0029] Respectively weigh ytterbium oxide Yb 2 o 3 , Nb(OH) 5 , Vanadium pentoxide V 2 o 5 , after grinding and mixing uniformly in an agate mortar, select the air atmosphere to pre-calcine at 420°C for 10 hours in a muffle furnace, then cool to room temperature, take out the sample, mix the mixture fully and grind evenly again, in the air atmosphere , calcined at 1050°C for 2 hours, cooled to room temperature, taken out and fully ground to obtain Yb 3 Nb 7 V 3 o 17 powder,

[0030] After stirring for one hour, filter and wash repeatedly, and finally calcine in the air atmosphere at 1300°C for 3 hours, cool to room temperature, take it out and grind it sufficiently to obtain the phosphor powder Yb 3 Nb 7 V 3 o 17 .

[0031] Coating preparation: Firstly, the unsaturated polyester resin solution and the methyl ethyl ketone peroxide solu...

Embodiment 3

[0033] The formula process is exactly the same as that of Example 1, except that the fluorescent powder is Yb 2.2 Nb 7.8 V 3 o 17

[0034] During the phosphor preparation process, the molar ratio of Yb ions: Nb ions: V ions is 2.2:7.8:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com