Arch-shaped counterfort vertical quay structure

An upright and arched technology, which is used in quay walls, water conservancy projects, marine engineering, etc., can solve the problems of poor economy, poor structural stability, and large fore-toe stress of buttressed structures, and achieves simple construction, lightweight structure, enhanced strength and so on. adaptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

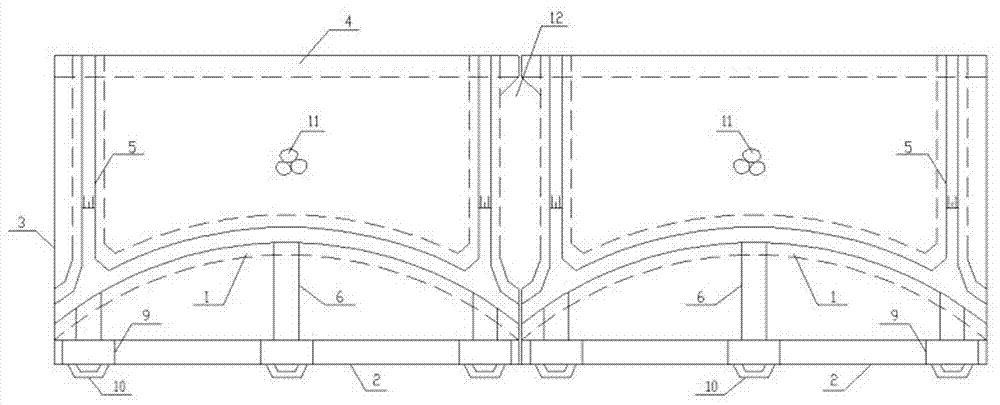

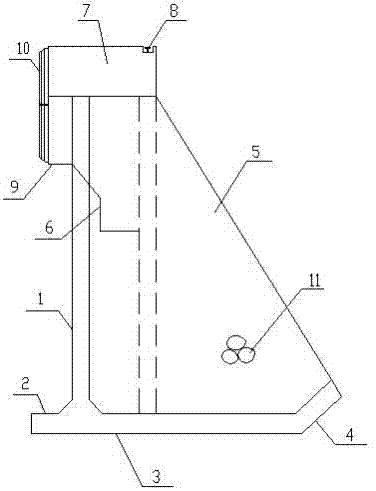

[0018] Such as Figure 1 to Figure 2 As shown, the arched buttress vertical wharf structure of the present invention includes a vertical plate 1, a front toe plate 2, an inner bottom plate 3, a tail plate 4, a rib plate 5, a corbel 6, a guide beam 7, a steel rail 8, and a berth member 9 , fender 10, backfill 11, filter well 12, the ribs are located on the inner side of the vertical plate 1, the front toe plate 2 and the inner bottom plate 3 are all located on the bottom of the vertical plate 1, the front toe plate 2, the inner bottom plate 3, The ribs 5 are all connected to the stern plate 4, the guide beam 7 is located on the top of the vertical plate 1, the ship member 9 and the fender 10 are located on one side of the corbel 6, and the middle of the corbel 6 and the vertical plate 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com