Metal buffer and buffer mechanism based on metal buffer

A technology of cushioning mechanism and cushioning parts, which is applied in the direction of mechanical equipment, shock absorbers, instruments, etc., can solve the problems of difficult to control the size and duration of impact force, large structural size, etc., and achieve low production cost, specific strength and specific stiffness Large, better than energy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to illustrate the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

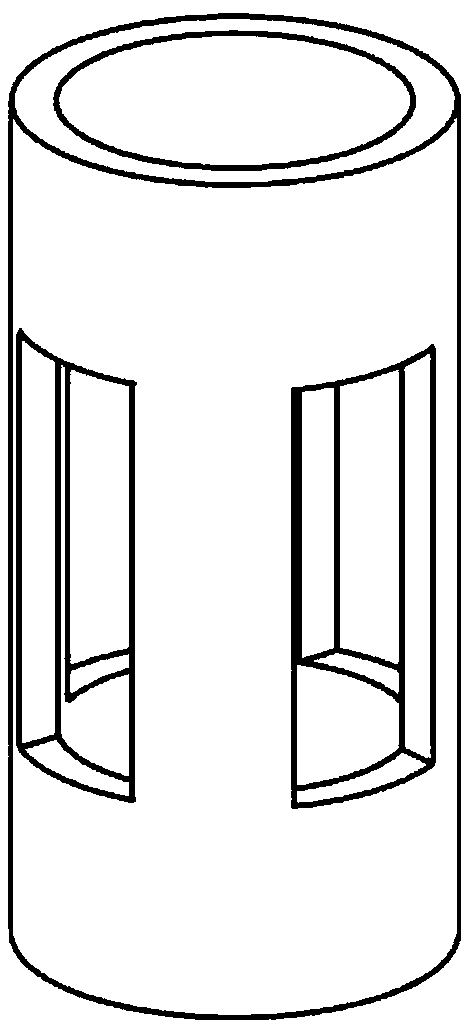

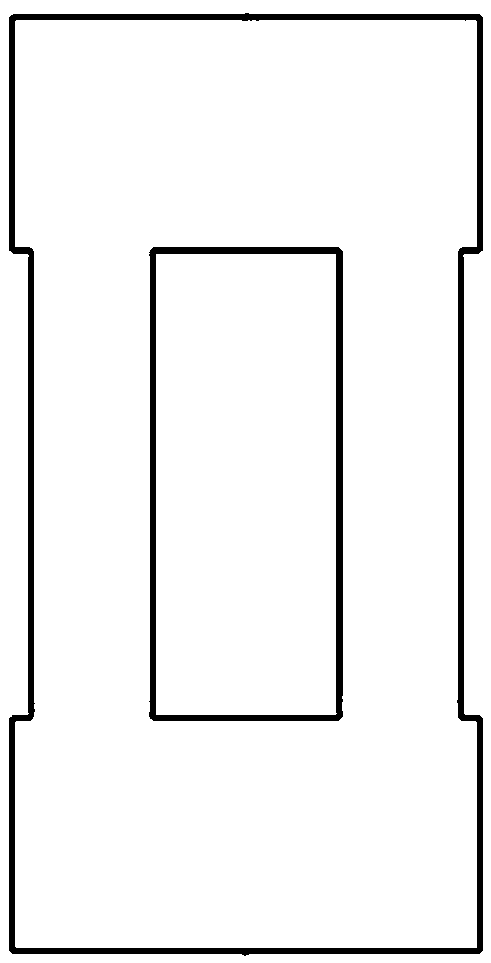

[0036] to combine Figure 1~3 , a metal buffer of the present invention, the metal buffer is a hollow cylindrical structure, and the side wall in the middle of the circumference of the cylindrical structure is evenly provided with n through holes communicating with the internal cavity, n≥2; the through holes It is a rectangular hole; the material of the metal buffer is copper;

[0037] Preferably, the number n of said through holes is 4. According to the simulation calculation results of the optimization software, when the number of openings on the side wall of the metal buffer is 4, the metal buffer can obtain a relatively suitable stiffness characteristic and achieve a good Buffer effect;

[0038] Further, the elastic modulus of the copper material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com