Single winding annular fluxgate current sensor

A current sensor and fluxgate technology, applied in the direction of only measuring current, voltage/current isolation, measuring current/voltage, etc., can solve the problem that the signal-to-noise ratio of the fluxgate signal is not high enough, reduce product reliability, and limit product versatility and other problems to achieve the effect of increasing product reliability, structural stability, and enhancing signal strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below with reference to the accompanying drawings and examples.

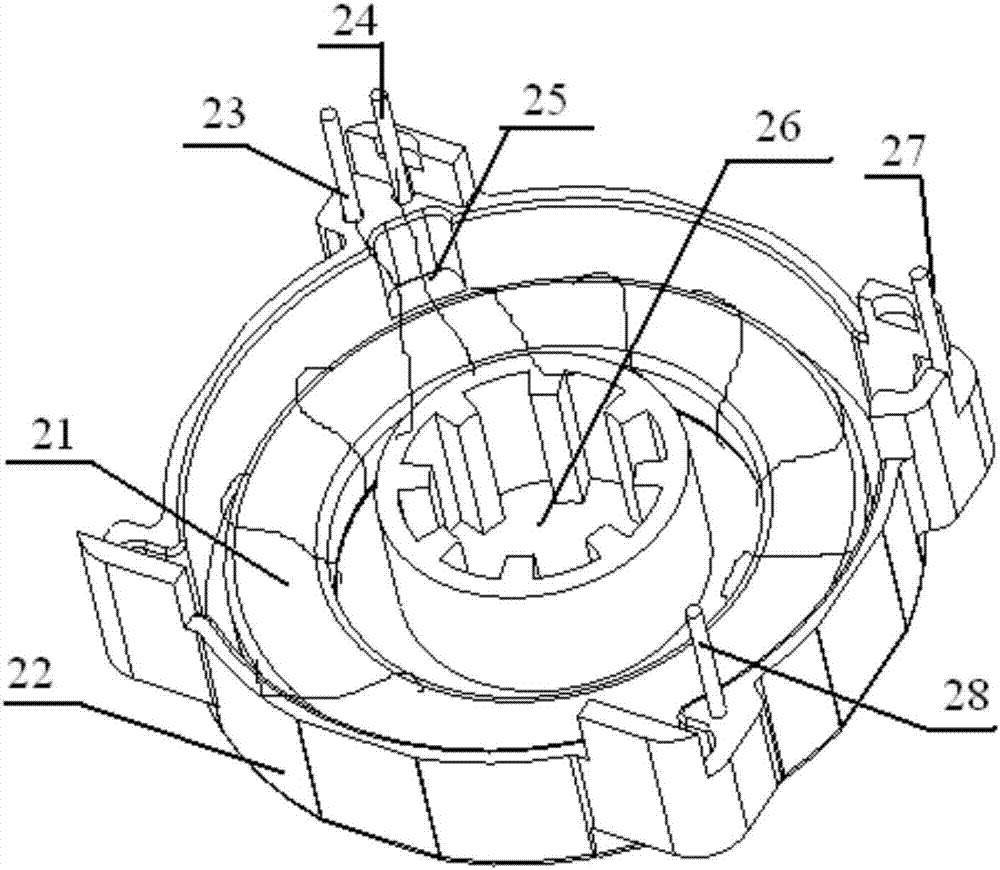

[0036] A single-winding toroidal fluxgate current sensor, comprising a fluxgate probe and a signal processing circuit;

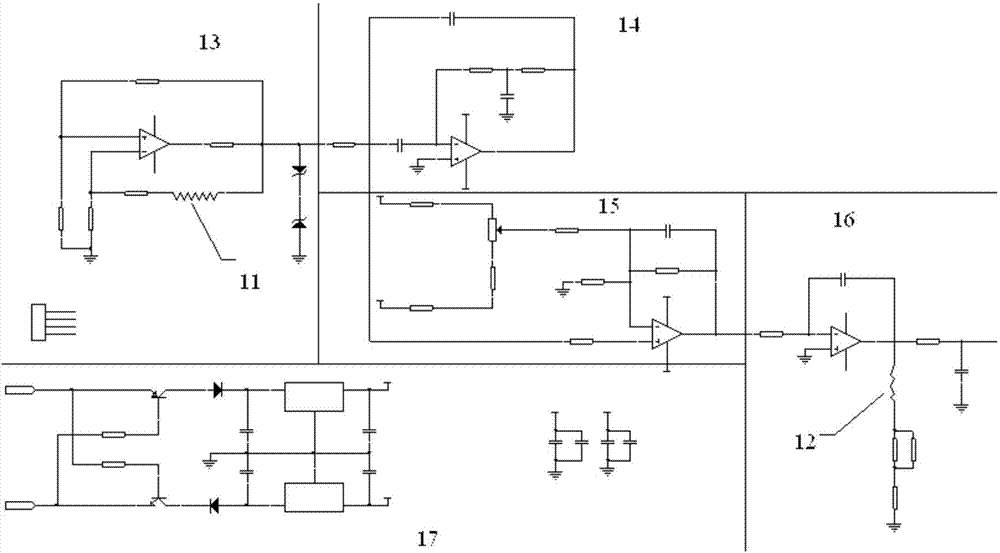

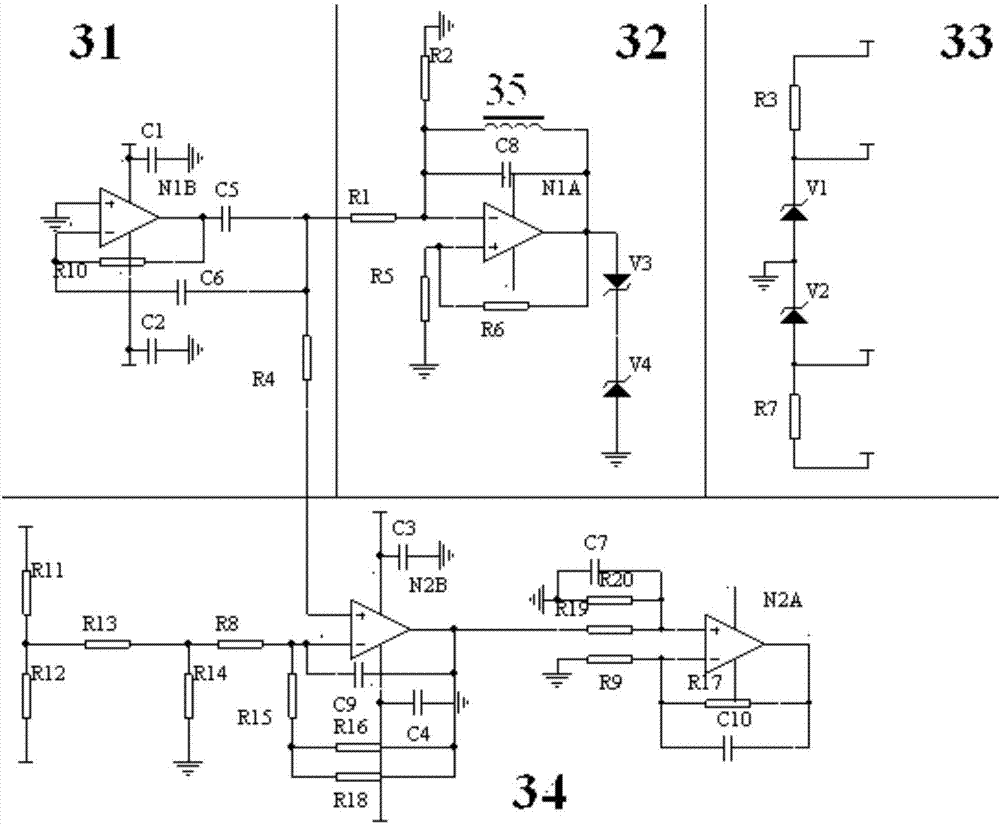

[0037] Such as image 3As shown, it is a schematic diagram of the sensor circuit of the present invention, and the signal processing circuit includes a filter circuit 31, an excitation circuit 32, a power supply circuit 33, a signal conditioning circuit 34 and a fluxgate probe 35, wherein the power supply circuit 33 provides the signal conditioning circuit 34 with Stabilize the voltage, the excitation circuit 32 provides an excitation signal to the fluxgate probe 35, so that the fluxgate probe 35 generates a fluxgate signal, the filter circuit 31 filters the fluxgate signal generated by the fluxgate probe 35, and the signal conditioning circuit 34 Correcting the zero point offset and sensitivity error of the signal processing circuit an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com