Modified silver nanowire transparent conductive film and method for enhancing electrical conductivity and oxidation resistance of silver nanowire transparent conductive film

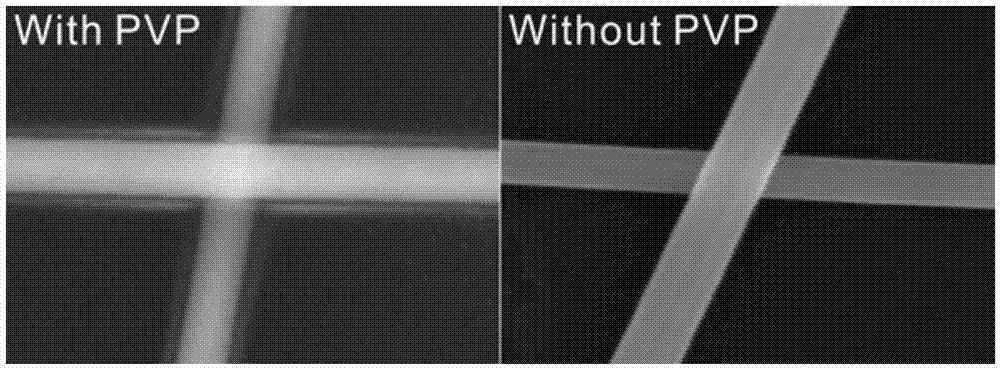

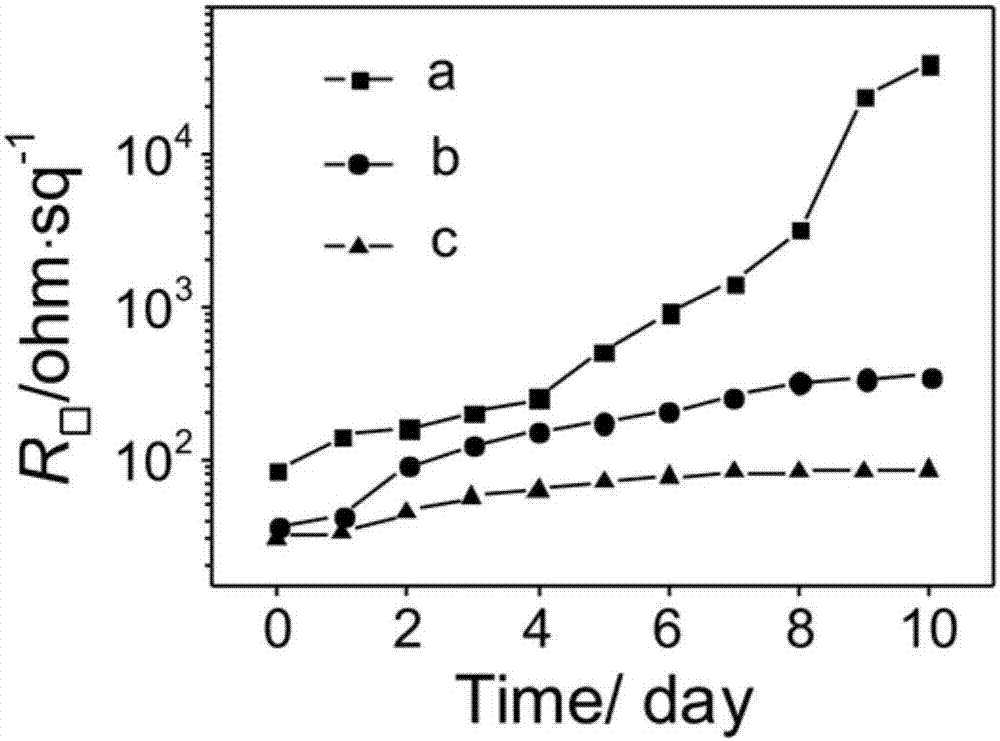

A technology of transparent conductive film and silver nanowire, which is applied in the direction of equipment for manufacturing conductive/semiconductive layers, conductive layers on insulating carriers, circuits, etc. The poor stability of the wire conductive film and other problems can be achieved to improve the oxidation resistance, the surface resistance is small, and the effect of improving the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

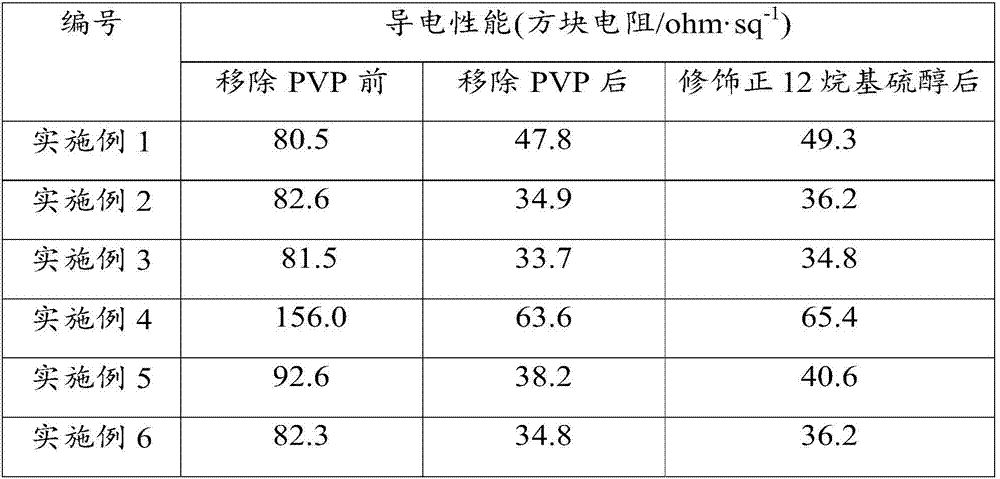

Embodiment 1

[0033] This embodiment provides a modified silver nanowire transparent conductive film, which is prepared by the following method:

[0034] First, NaBH with ethanol-water as a mixed solvent 4 The solution carries out the first surface treatment to the silver nanowire transparent conductive film; Wherein, the first surface treatment is to make the silver nanowire transparent conductive film at a concentration of 0.4mol / LNaBH 4 Soak in the ethanol / water solution for 1s, and the ethanol / water solution is a solution with a volume ratio of ethanol to water of 2-3. After soaking, take out the transparent conductive film of silver nanowires and use ethanol and water to remove the residual NaBH successively. 4 Rinse well, then dry naturally or gently dry the transparent conductive film with nitrogen.

[0035] Secondly, the silver nanowire transparent conductive film that has undergone the first surface treatment is contacted with n-12 alkyl mercaptan and ethanol to perform the secon...

Embodiment 2

[0037] This embodiment provides a modified silver nanowire transparent conductive film, which is prepared by the following method. The difference between this method and the method provided in Example 1 is:

[0038] First, NaBH with ethanol-water as a mixed solvent 4 The solution carries out the first surface treatment to the silver nanowire transparent conductive film; Wherein, the first surface treatment is to make the silver nanowire transparent conductive film at a concentration of 0.5mol / LNaBH 4 Soak in the ethanol / water solution for 30s, and the ethanol / water solution is a solution with a volume ratio of ethanol to water of 1:1. After soaking, take out the transparent conductive film of silver nanowires and use ethanol and water to remove the residual NaBH successively. 4 Rinse well, then dry naturally or gently dry the transparent conductive film with nitrogen.

[0039] Secondly, the silver nanowire transparent conductive film that has undergone the first surface trea...

Embodiment 3

[0041] This embodiment provides a modified silver nanowire transparent conductive film, which is prepared by the following method. The difference between this method and the method provided in Example 1 is:

[0042] First, NaBH with ethanol-water as a mixed solvent 4 The solution carries out the first surface treatment to the silver nanowire transparent conductive film; Wherein, the first surface treatment is to make the silver nanowire transparent conductive film at a concentration of 0.6mol / LNaBH 4 Soak in the ethanol / water solution for 70s, and the ethanol / water solution is a solution with a volume ratio of ethanol to water of 3:2. After soaking, take out the transparent conductive film of silver nanowires and use ethanol and water to remove the residual NaBH successively. 4 Rinse well, then dry naturally or gently dry the transparent conductive film with nitrogen.

[0043] Secondly, the silver nanowire transparent conductive film that has undergone the first surface trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com