Preparation method of BiVO4/TiO2 core-shell composite photocatalyst

A composite light and catalyst technology, applied in the field of photocatalysis, to achieve good visible light photocatalytic activity, simple and controllable preparation method, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

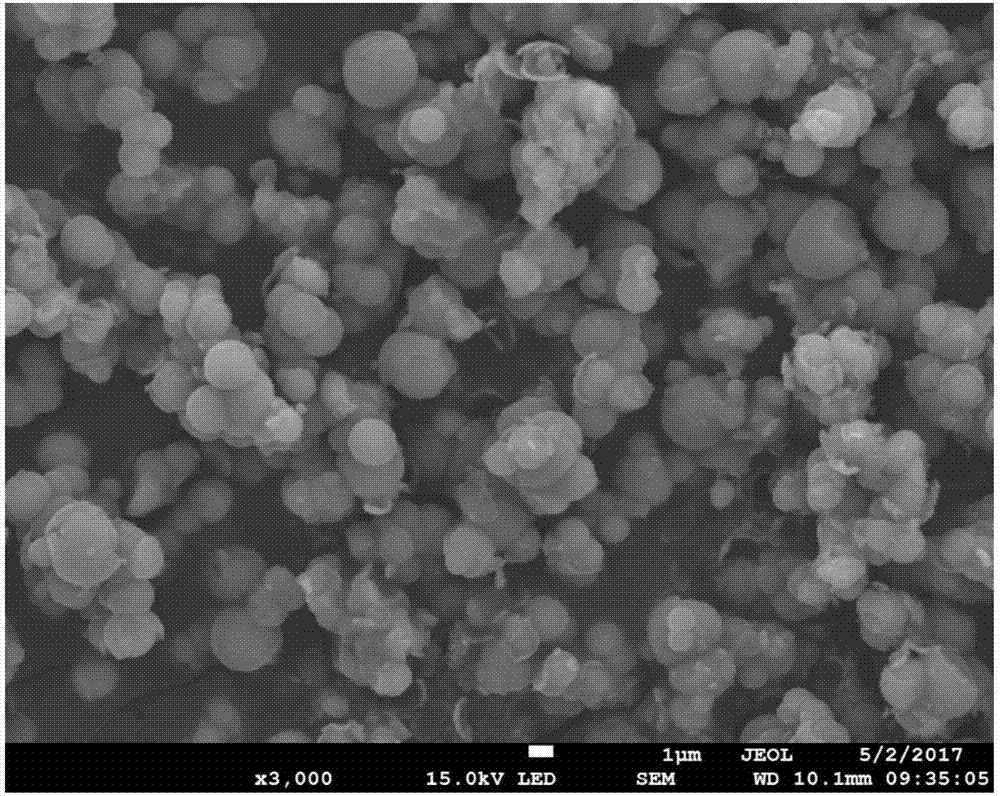

[0039] figure 1 and figure 2 For the BiVO prepared in Example 1 of the present invention 4 / TiO 2 Schematic diagram of the surface morphology of the core-shell composite photocatalyst, using the BiVO prepared in Example 1 of the present invention 4 / TiO 2 The photocatalytic powder is a large particle with a core-shell structure.

[0040] image 3 and Figure 4 For the BiVO prepared in Example 1 of the present invention 4 / TiO 2 The EDS test positions A and B of the core-shell composite photocatalyst, using the BiVO prepared in Example 1 of the present invention 4 / TiO 2 The core-shell composite photocatalyst support is TiO 2, the cladding layer contains V and Bi elements.

[0041] Figure 5 For the BiVO prepared in Example 1 of the present invention 4 / TiO 2 The XRD spectrum of the core-shell composite photocatalyst, using the BiVO prepared in Example 1 of the present invention 4 / TiO 2 The core-shell composite photocatalyst is mainly composed of TiO 2 .

[...

Embodiment 2

[0048] Figure 6 and Figure 7 For the BiVO prepared in Example 2 of the present invention 4 / TiO 2 Schematic diagram of the surface morphology of the core-shell composite photocatalyst, using the BiVO prepared in Example 2 of the present invention 4 / TiO 2 The photocatalytic powder is a large particle with a core-shell structure.

[0049] Figure 8 and Figure 9 For the BiVO prepared in Example 2 of the present invention 4 / TiO 2 The EDS test positions C and D of the core-shell composite photocatalyst, using the BiVO prepared in Example 2 of the present invention 4 / TiO 2 The core-shell composite photocatalyst support is mainly TiO 2 , the transition layer contains a small amount of Bi and V elements, and the Bi and V elements in the cladding layer increase, indicating that the cladding layer is BiVO 4 .

[0050] Figure 10 For the BiVO prepared in Example 2 of the present invention 4 / TiO 2 The XRD spectrum of the core-shell composite photocatalyst, using the ...

Embodiment 3

[0058] Will 32gTiOSO 4 Add it into deionized water, fully stir and dissolve, and prepare a 1000mL solution with a concentration of 0.2mol / L; take a certain amount of TiOSO 4 solution, according to Ti:(NH 4 )=1:2 add urea, continue to stir until the urea is completely dissolved; transfer the mixed solution to a three-necked flask, heat to 95°C and keep it warm for 5h, white precipitate appears in the solution during the heating process; after the reaction is completed, the reaction product is used Centrifuge and wash with deionized water until neutral, then dry in an oven at 60°C; put the prepared powder in a muffle furnace for heat treatment, the heating system is: raise the temperature at 5°C / min to 300°C for 1 hour, Then heat up to 500°C at 5°C / min for 2h to obtain TiO 2 Carrier powder; 0.06gBi(NO 3 ) 3 ·5H 2 O was dissolved in 30mL deionized water and stirred until completely dissolved; 0.014gNH 4 VO 3 Dissolve in 30mL of deionized water at 50℃, stir until completely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com