On-site real-time temperature compensation method of industrial robot based on vision sensor

A vision sensor, industrial robot technology, applied in temperature control, instruments, measuring devices, etc., can solve problems such as robot motion trajectory deviation, achieve the effect of small debugging workload, ensure repeated positioning accuracy, and simple and convenient calibration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0042] This embodiment discloses a visual sensor-based on-site real-time temperature compensation method for an industrial robot. The temperature compensation method uses a binocular stereo vision sensor to measure and position the TCP point at the end of the robot:

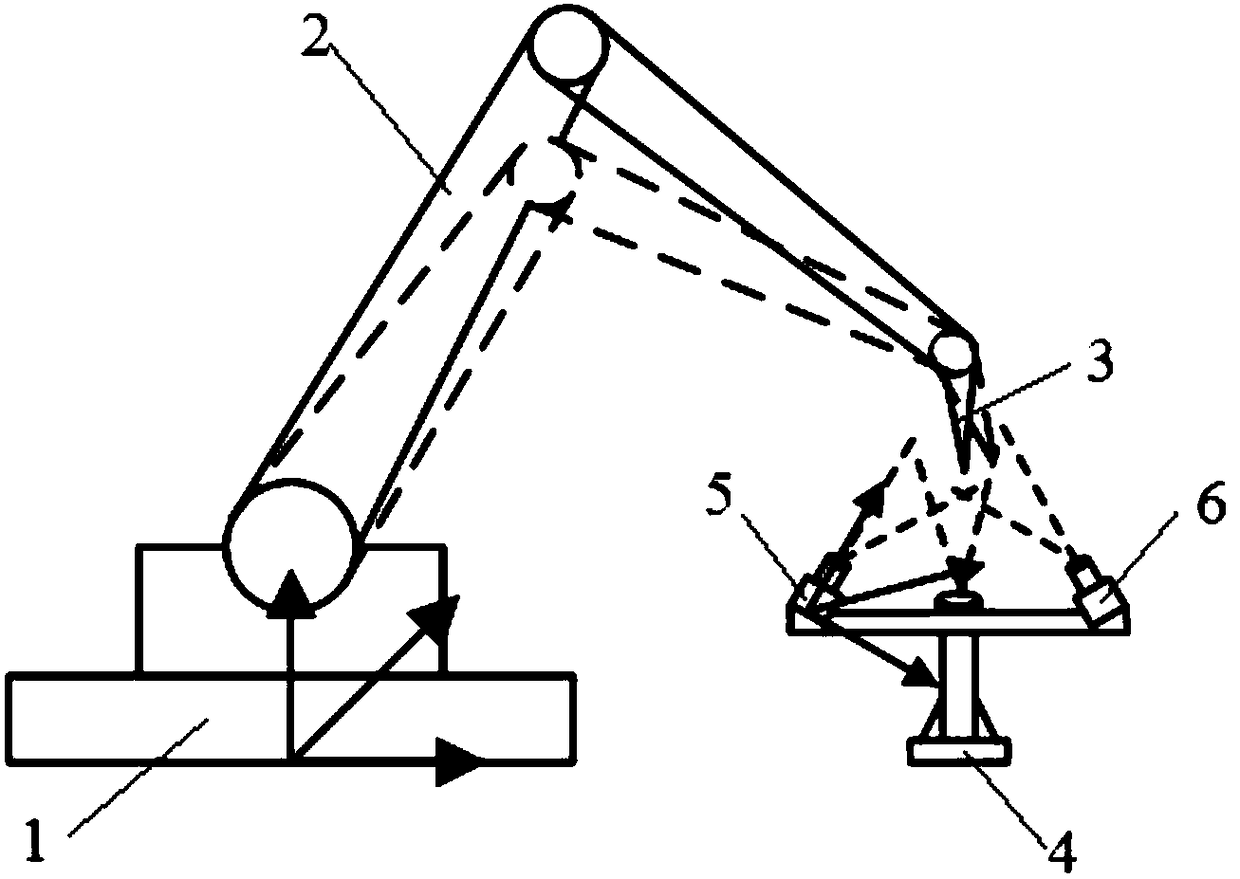

[0043] Such as figure 1 As shown, under the premise of satisfying the working distance of the sensor and measuring the depth of field, a binocular stereo vision sensor is installed near the robot base 1. The center of the top of the robot base 1 is the industrial robot 2, and the end of the industrial robot 2 is connected to the tool 3; The coordinate system is established with the center point of the bottom of the robot base 1.

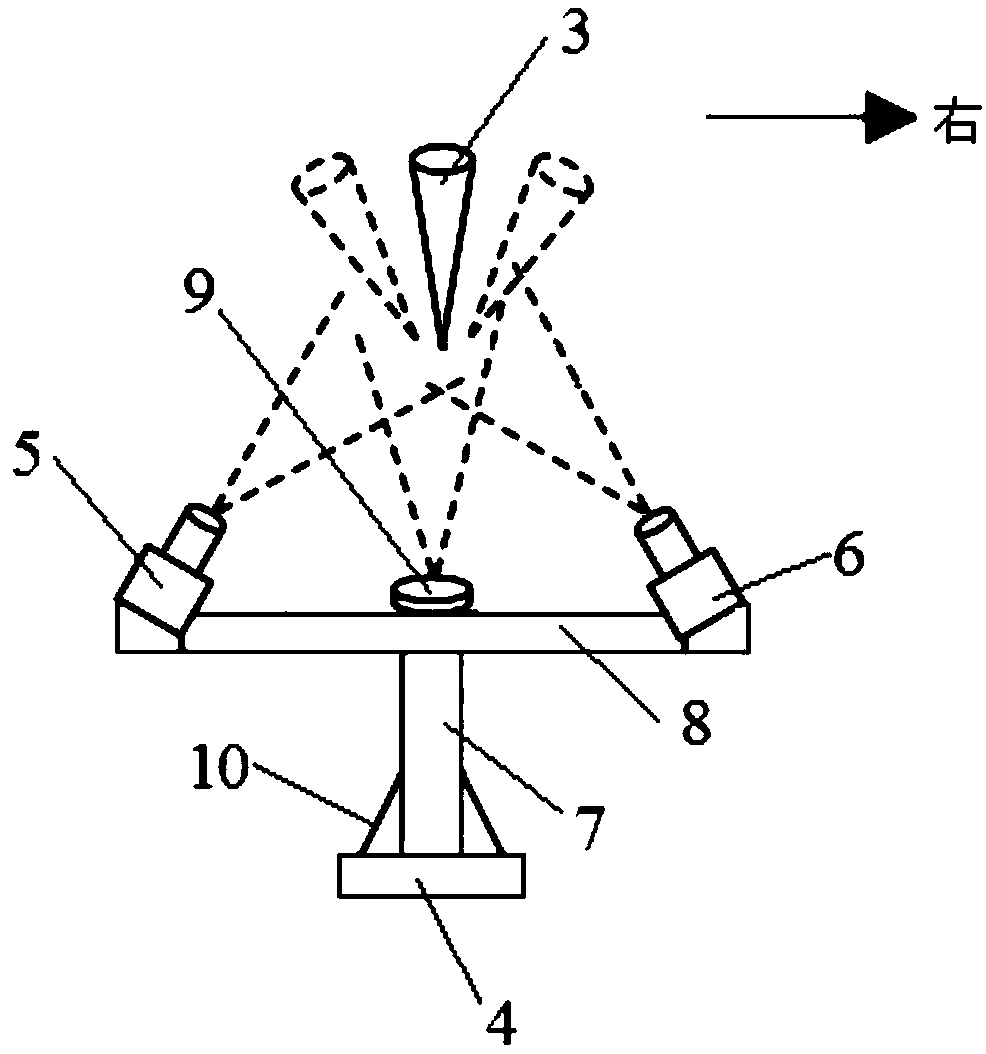

[0044] Such as figure 2As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com