Energy-saving and consumption-reducing shortcut nitrification-denitrification phosphorus removal technology

A technology for denitrification and phosphorus removal and short-range nitrification, which is applied in the field of energy-saving and consumption-reducing short-range nitrification and denitrification and phosphorus removal technology, and can solve the problems of difficulty in accumulating nitrite nitrogen, unstable nitrite accumulation, and inability to effectively remove nitrogen and phosphorus. , to achieve the effect of stable short-range nitrification, saving aeration amount and reducing denitrifying carbon source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the objects and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0018] The embodiment of the present invention provides an energy-saving and consumption-reducing short-range nitrification and denitrification phosphorus removal process, which includes the following steps:

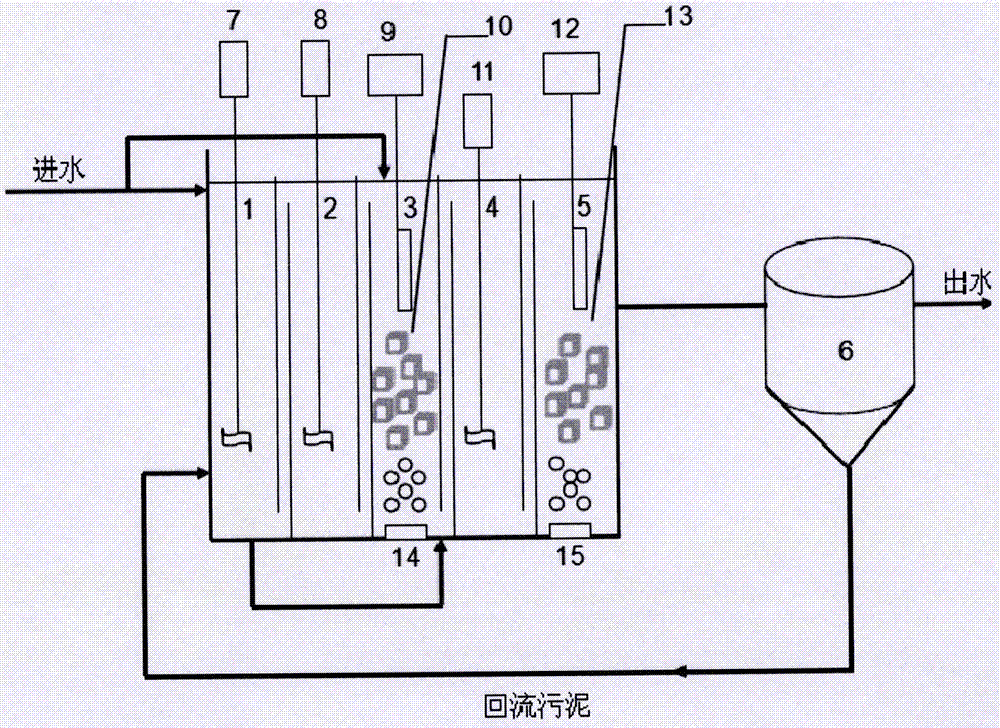

[0019] S1, press as figure 1 The shown structural assembly reaction device includes an integrated reactor and a sedimentation tank 6, and the integrated reactor is provided with an anaerobic reactor 1, the first anoxic reactor 2, the first aerobic reactor 3, and the second anaerobic reactor. Oxygen reactor 4 and the second aerobic reactor 5 are connected in sequence, agitators 7, 8, 11 are respectively arranged in the anaerobic reactor 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com