Air cycle machine fan and compressor housings

A technology of air cycle machines and compressors, which is applied in the direction of machines/engines, air handling equipment, mechanical equipment, etc., and can solve problems such as damaged fan sections, system performance degradation, and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

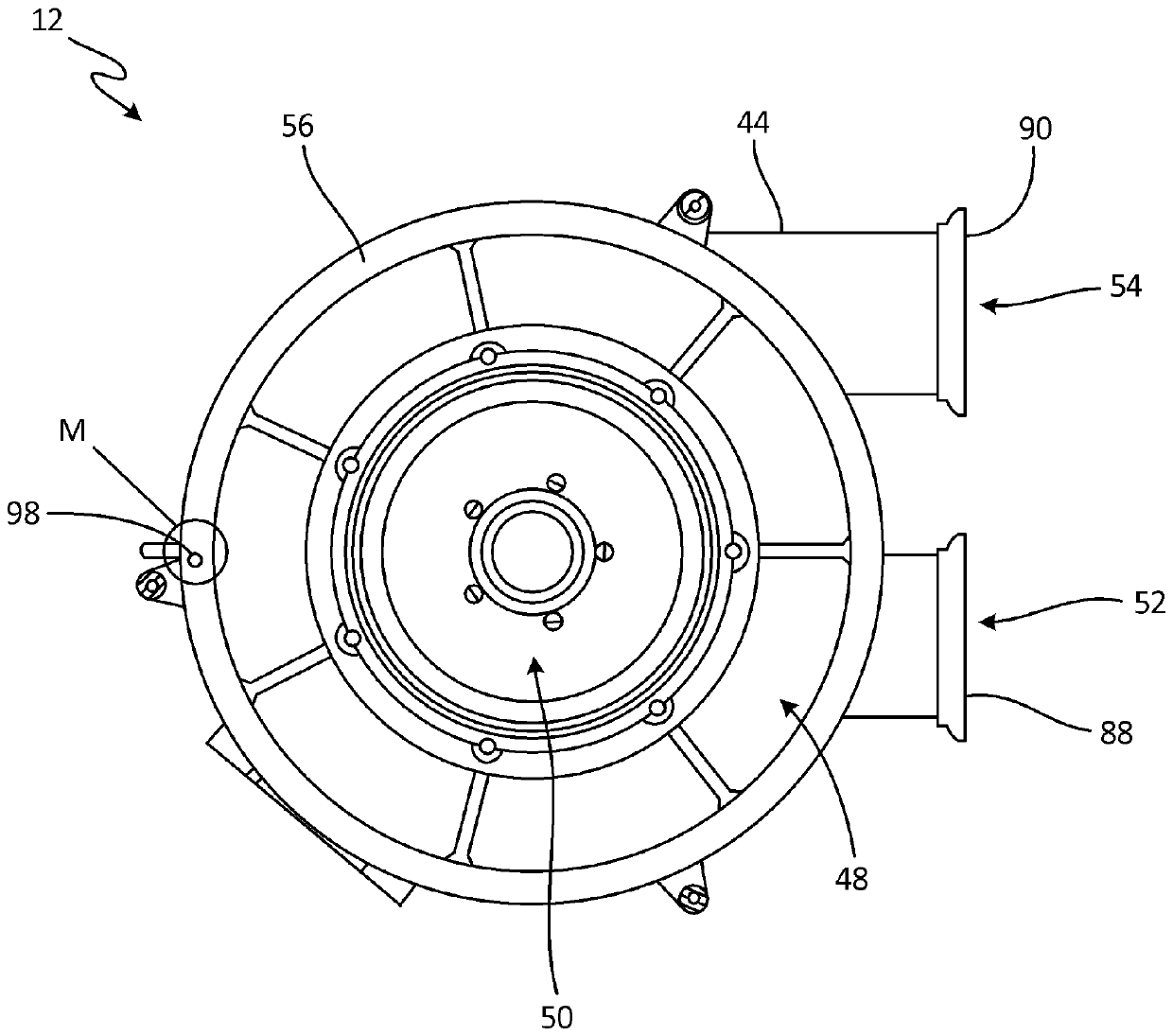

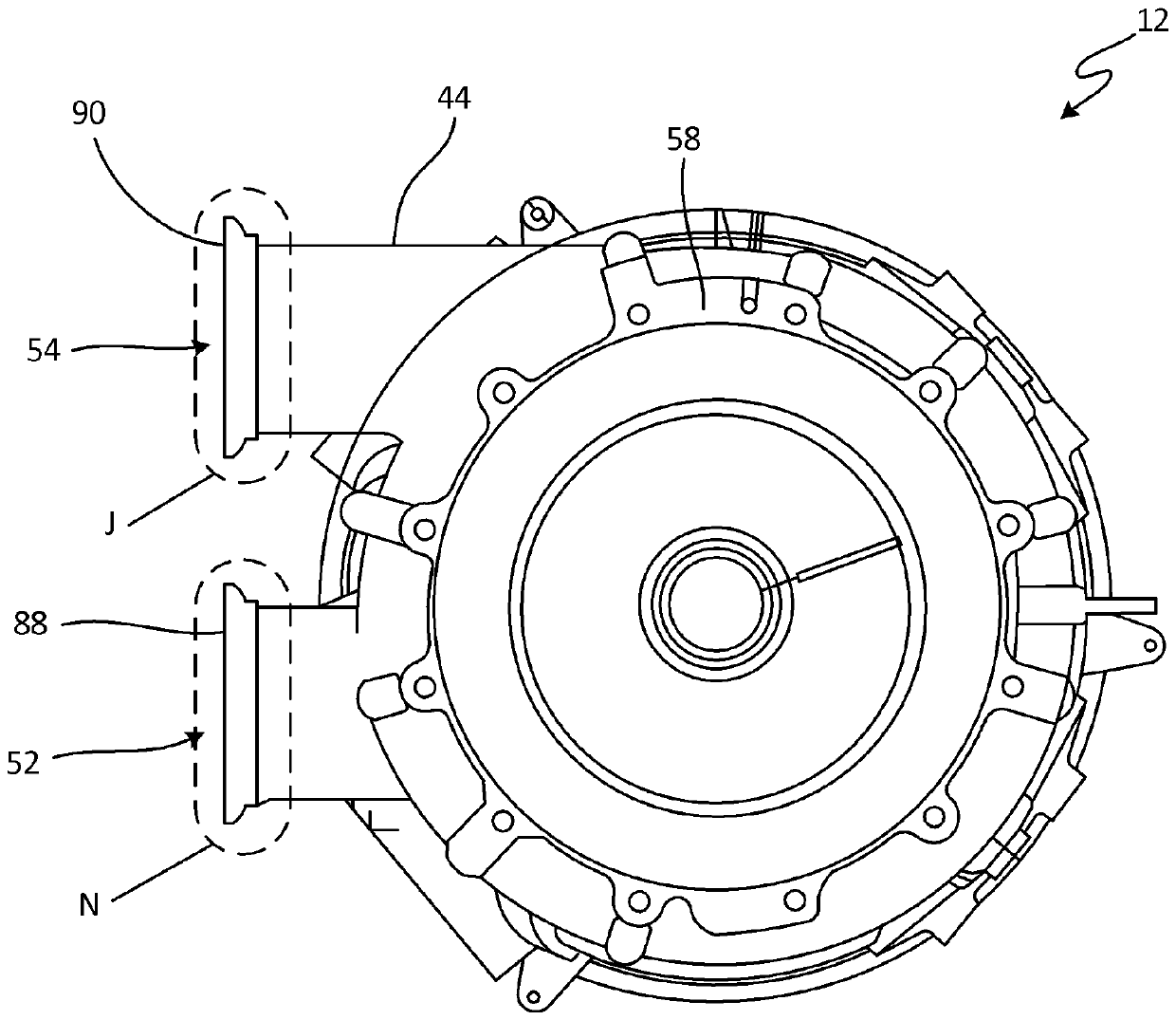

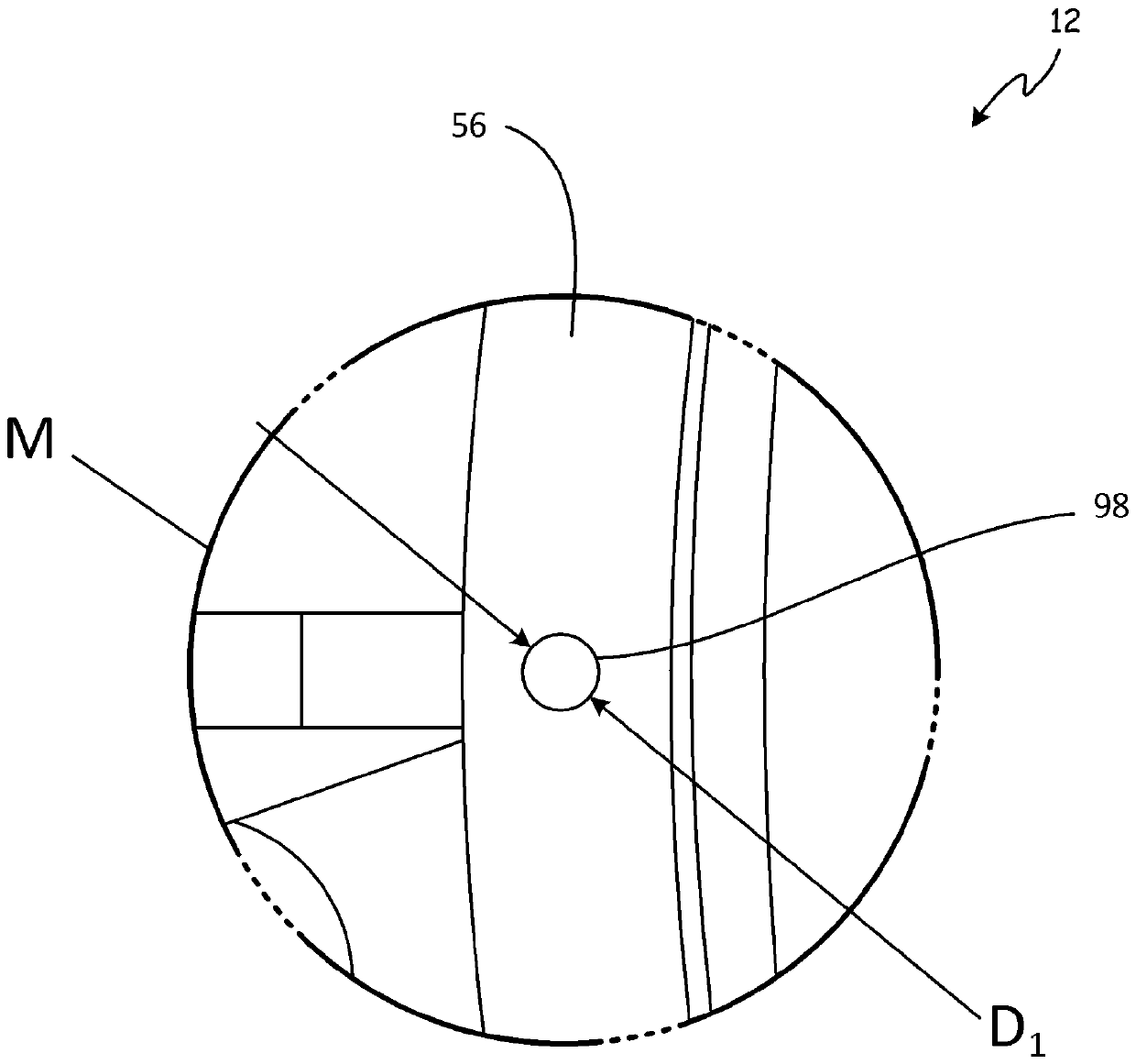

[0017] figure 1 is a perspective view of an air cycle machine (ACM) assembly 2 comprising: a fan inlet diffuser 4 with a fan inlet diffuser housing 6 , a condenser / reheater 8 and an ACM 10 . As shown, the ACM 10 includes a fan and compressor section 12 (including a compressor section 12C and a fan section 12F), a first turbine section 14 , and a second turbine section 16 .

[0018] The fan inlet diffuser 4 is connected to the condenser / reheater 8 and the ACM 10 . Condenser / reheater 8 is joined to fan inlet diffuser 4 and ACM 10 . ACM 10 is coupled to fan inlet diffuser 4 and condenser / reheater 8 . Fan and compressor section 12 is connected to fan inlet diffuser 4 , condenser / reheater 8 and first turbine section 14 . Fan section 12F of fan and compressor section 12 is connected to fan inlet diffuser housing 6 of fan inlet diffuser 4 . Compressor section 12C is connected to condenser / reheater 8 and first turbine inlet section 14 . First turbine section 14 is joined to conde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com