Internal pressure-deformable liner for lining of existing pipelines and method of use thereof

A technology for lining pipes and pipes, applied in the direction of pipes/pipe joints/fittings, pipe components, mechanical equipment, etc. Leakage and other problems, to achieve the effect of not easy to adhere to dirt, simple structure, and enhanced adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

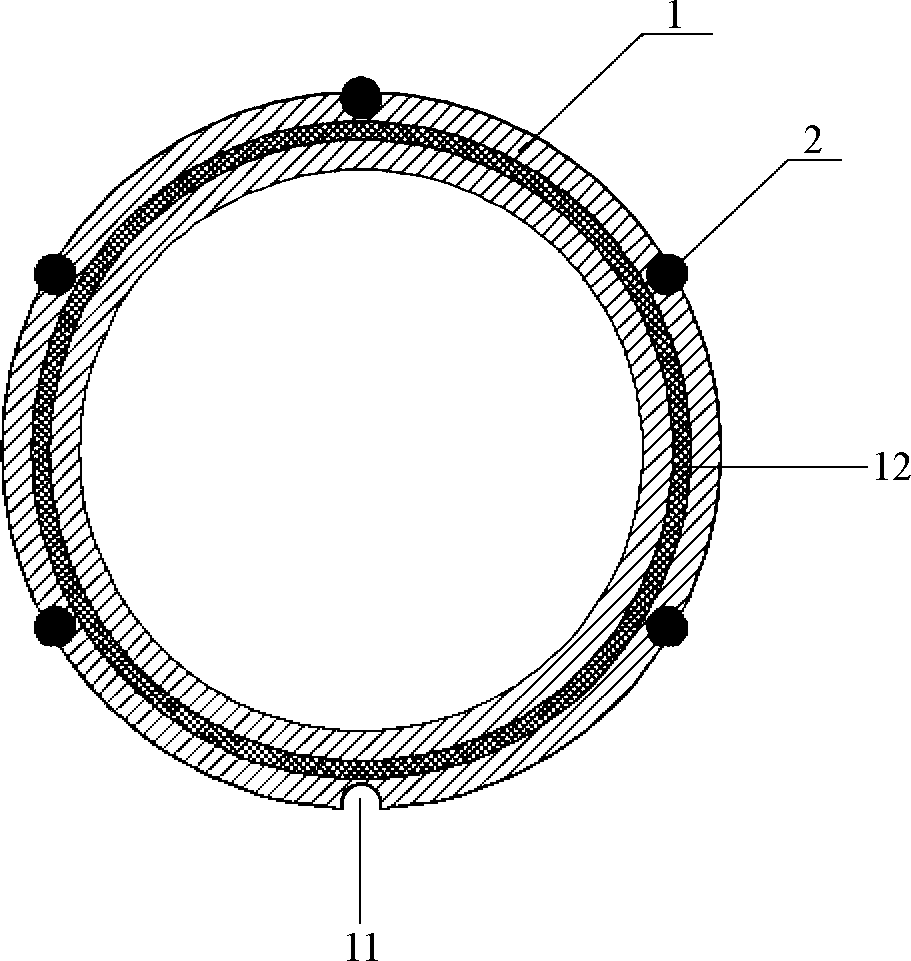

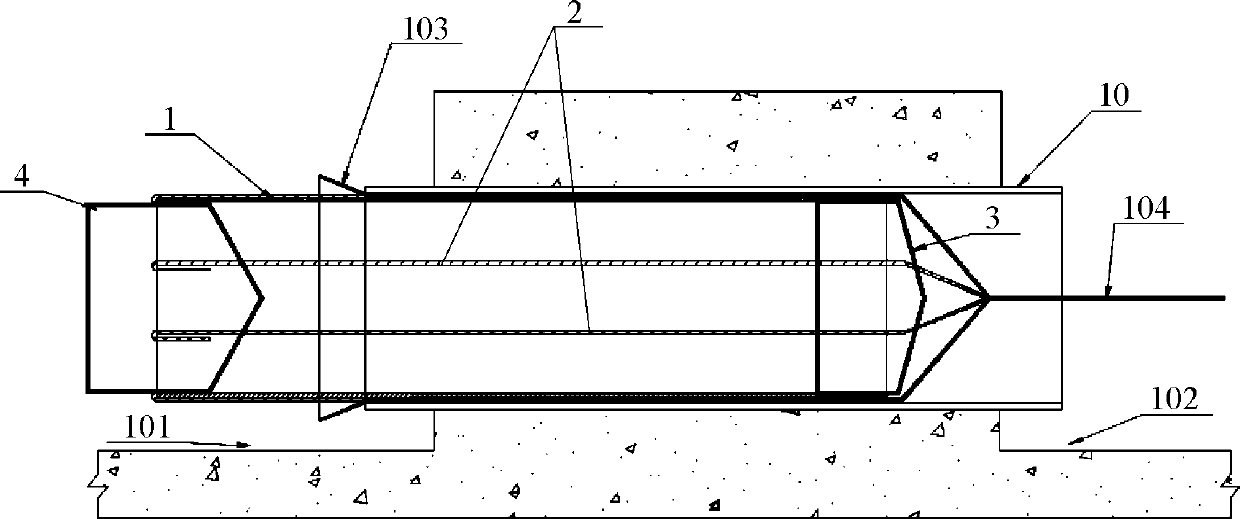

[0040] An internal pressure-deformable lining pipe used for the lining of existing pipelines, including a hollow connecting pipe 1 and a fillet 2, such as figure 1 As shown, the specific structure is:

[0041] The outer wall of the connecting pipe 1 is provided with six slots 11 with an arc-shaped cross section, and the slots 11 are evenly distributed around the central axis of the connecting pipe 1;

[0042] The fillet 2 can be wire or optical fiber, the cross-section of the fillet 2 is circular, the radius of the cross-section of the fillet 2 is not greater than the radius of curvature of the cross-section of the fillet 11, and the diameter of the fillet 2 is greater than the depth of the cross-section of the fillet 11 , a fillet 2 is embedded in each caulking groove 11, the outermost part of the outer surface of the fillet 2 is higher than the outermost part of the outer side wall of the connecting pipe 1, and the two ends of the fillet 2 protrude from the front and rear si...

Embodiment 2

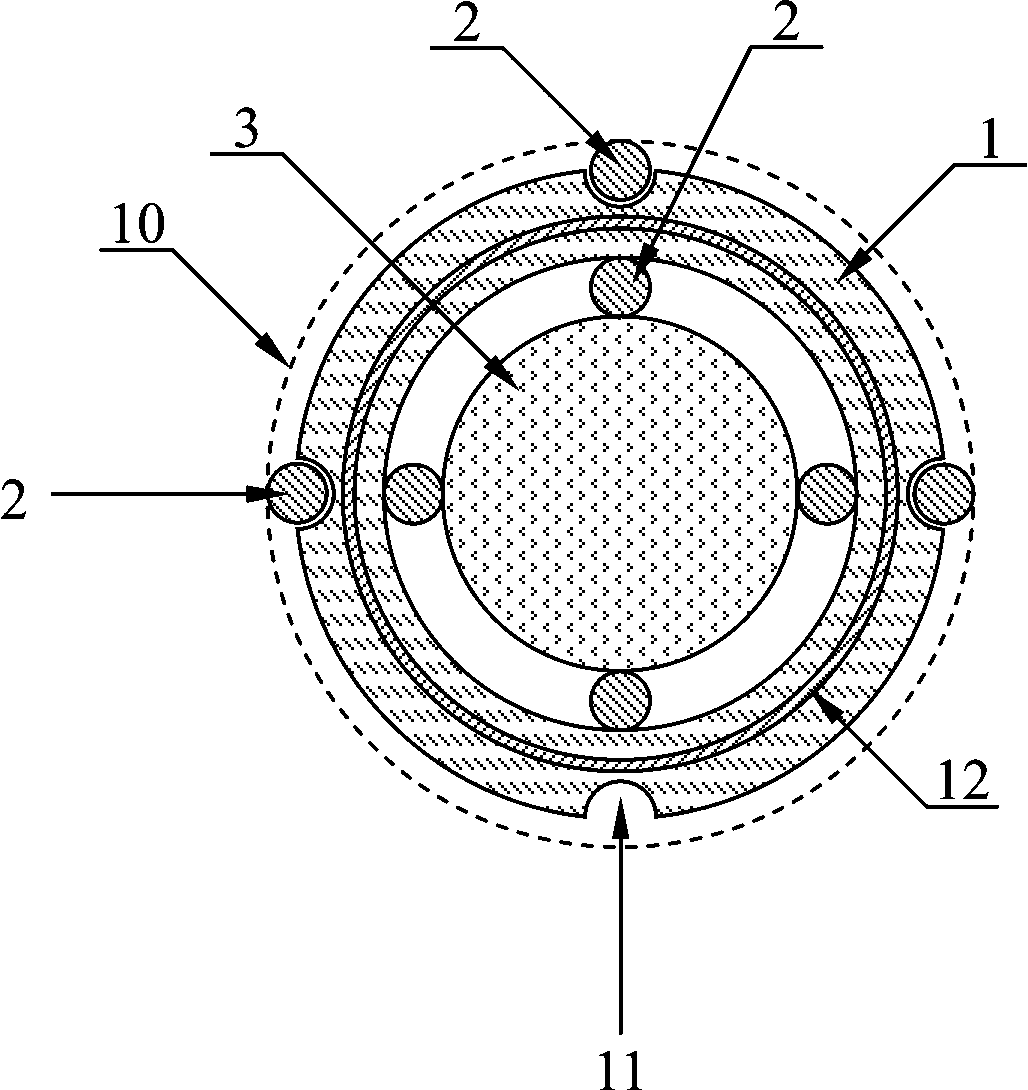

[0054] An internal pressure-deformable lining pipe used for the lining of existing pipelines, including a hollow connecting pipe 1 and a fillet 2, such as figure 2 As shown, the specific structure is:

[0055] The outer wall of the connecting pipe 1 is provided with four slots 11 with an arc-shaped cross section, and the slots 11 are evenly distributed around the central axis of the connecting pipe 1;

[0056] Nylon rope or steel wire rope can be used for the fillet 2. The cross section of the fillet 2 is circular. The radius of the cross section of the fillet 2 is not greater than the radius of curvature of the cross section of the fillet 11. Depth, a fillet 2 is embedded in each insert groove 11, and the outermost part of the outer surface of the fillet 2 is figure 2 The dotted line in the circle shows that it is higher than the outermost part of the outer wall of the connecting pipe 1. The two ends of the fillet 2 protrude from the front and rear ends of the connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com