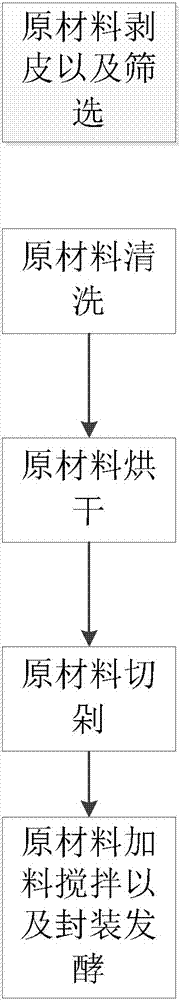

Fermented chili production process

A production process and a technology for fermented chili peppers, applied in the field of fermented chili pepper production techniques, can solve the problems of wasting manpower, increasing time, uneven stirring, etc., and achieve the effects of saving manpower and material resources, preventing side drying, and stirring evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below by means of specific embodiments:

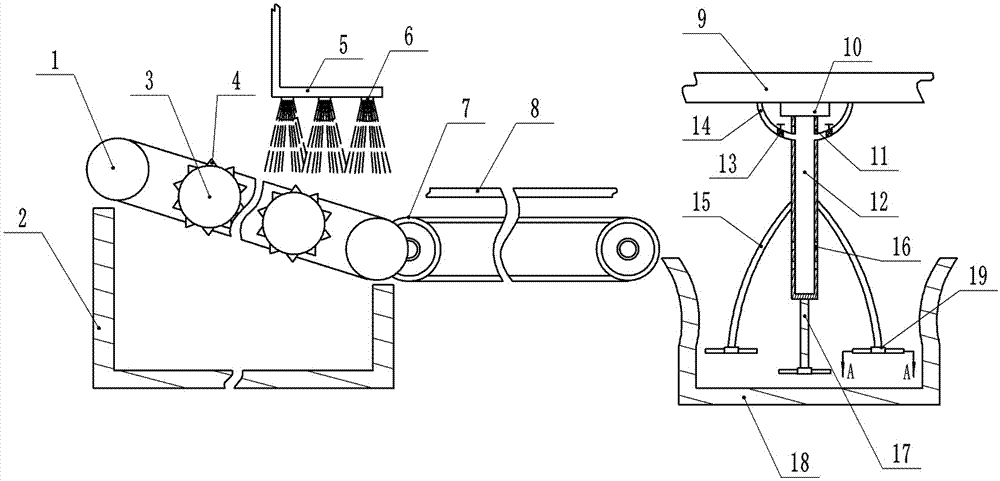

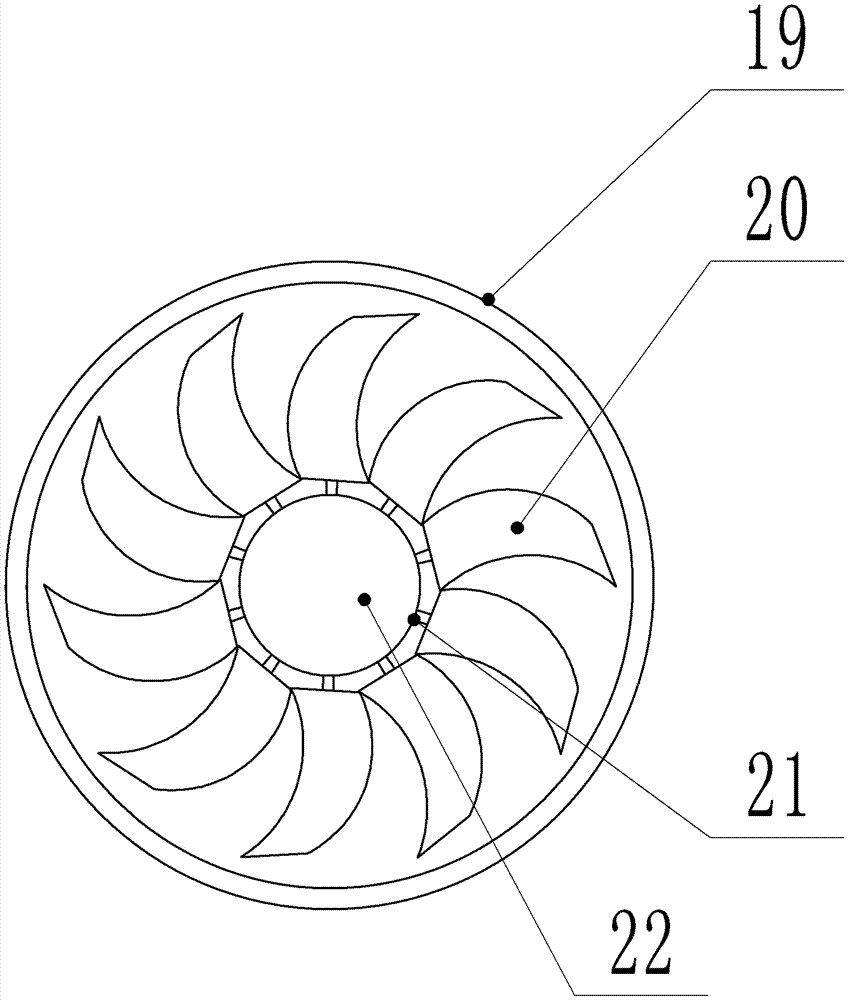

[0031] The reference signs in the drawings of the description include: roller conveyor 1, collection box 2, drive roller 3, spikes 4, water pipe 5, water mist sprayer 6, belt conveyor 7, ultraviolet dryer 8, bracket 9. Motor 10, valve plate 11, main pipe 12, valve 13, delivery pipe 14, hose 15, oil hole 16, support rod 17, storage tank 18, stirring device 19, stirring blade 20, fixed rod 21, rotating shaft 22 .

[0032] The embodiment is basically as attached Figure 2-3 Shown: The production process of bad pepper requires the help of a kind of equipment for producing bad pepper to process bad pepper. The equipment includes a peeling and cleaning mechanism, a drying mechanism and a stirring and pickling mechanism arranged in sequence. The peeling and cleaning mechanism includes a roller conveyor 1 , spray washing device and collection box 2, wherein, roller conveyor 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com