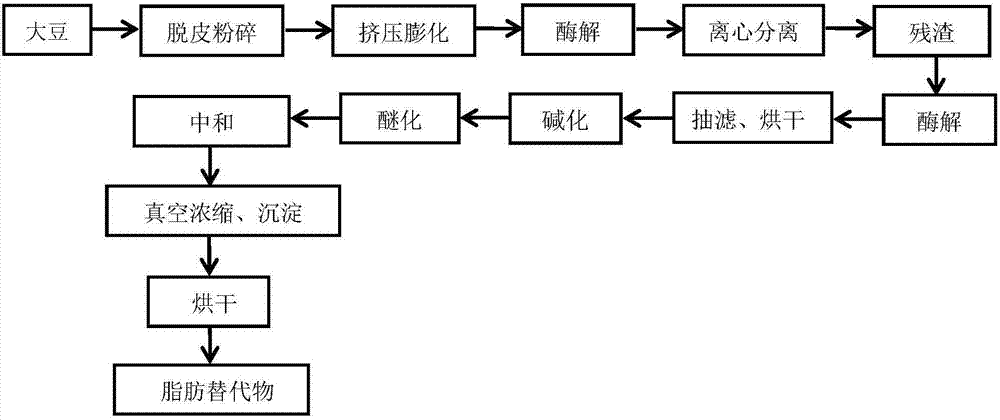

Method for preparing fat substitute from aqueous enzymatic method soybean dregs

A fat substitute, soybean residue technology, applied in application, food science, function of food ingredients, etc., can solve problems such as difficult to apply food processing, severe pressing and desolvation conditions, protein denaturation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Pulverize the full-fat soybean flakes, adjust the water content to 15%, extrude and puff to obtain puffed products, pour water into the enzymolysis reaction tank, pass in steam at 50°C for heating, and add crushed The puffed product of the sieve is mixed to obtain a mixed solution, and the ratio of material to liquid is adjusted to be 1:6, and the pH of the mixed solution is adjusted to 8.5 by using 2mol / L NaOH solution, and alkaline protease with a mass fraction of 2% of the puffed product is added to the mixed solution for enzymatic The enzymolysis time is 3 hours. After enzymolysis, a three-phase horizontal centrifuge is used to centrifuge and separate the emulsified oil, hydrolyzate and residue components; after collecting the residue components, wash 3 times with water at a solid-liquid ratio of 1:10, and After separation, dry at 60°C and crush; mix the residue with heated water at a material-to-liquid ratio of 1:6, and then add high-temperature-resistant α-amylase ...

Embodiment 2

[0016] Grind the full-fat soybean flakes, adjust the water content to 14.5%, extrude and expand to obtain the expanded product, pour water into the enzymolysis reaction tank, pass in steam at 55°C for heating, and add crushed The expanded product of the sieve is mixed to obtain a mixed solution, the ratio of material to liquid is adjusted to 1:6, the pH of the mixed solution is adjusted to 9.0 with 5mol / L NaOH solution, and alkaline protease with 1.85% of the expanded product mass is added to the mixed solution for enzymolysis , the enzymolysis time is 3h, and after enzymolysis, a three-phase horizontal centrifuge is used for centrifugation to obtain emulsified oil, hydrolyzate and residue components; Finally, dry at 50°C and crush; mix the residue with heated water at a material-to-liquid ratio of 1:6, and then add high-temperature-resistant α-amylase for enzymatic hydrolysis. The hydrolysis temperature is 85°C, and the pH of the enzymatic hydrolysis is 7.0. The hydrolysis ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com