A kind of porous graphene/molecular sieve composite film acid catalyst and its preparation method and application

A technology of porous graphene and composite film, which is applied in the field of preparation and application of catalytic materials to achieve the effects of improving acid strength and cycle performance, high reproducibility and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

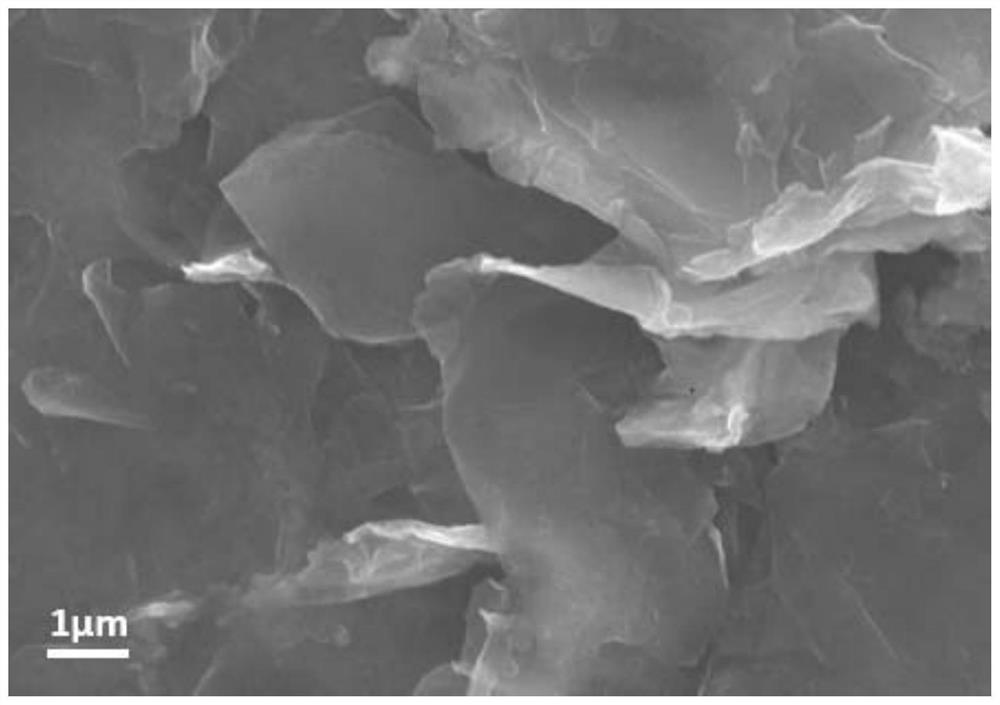

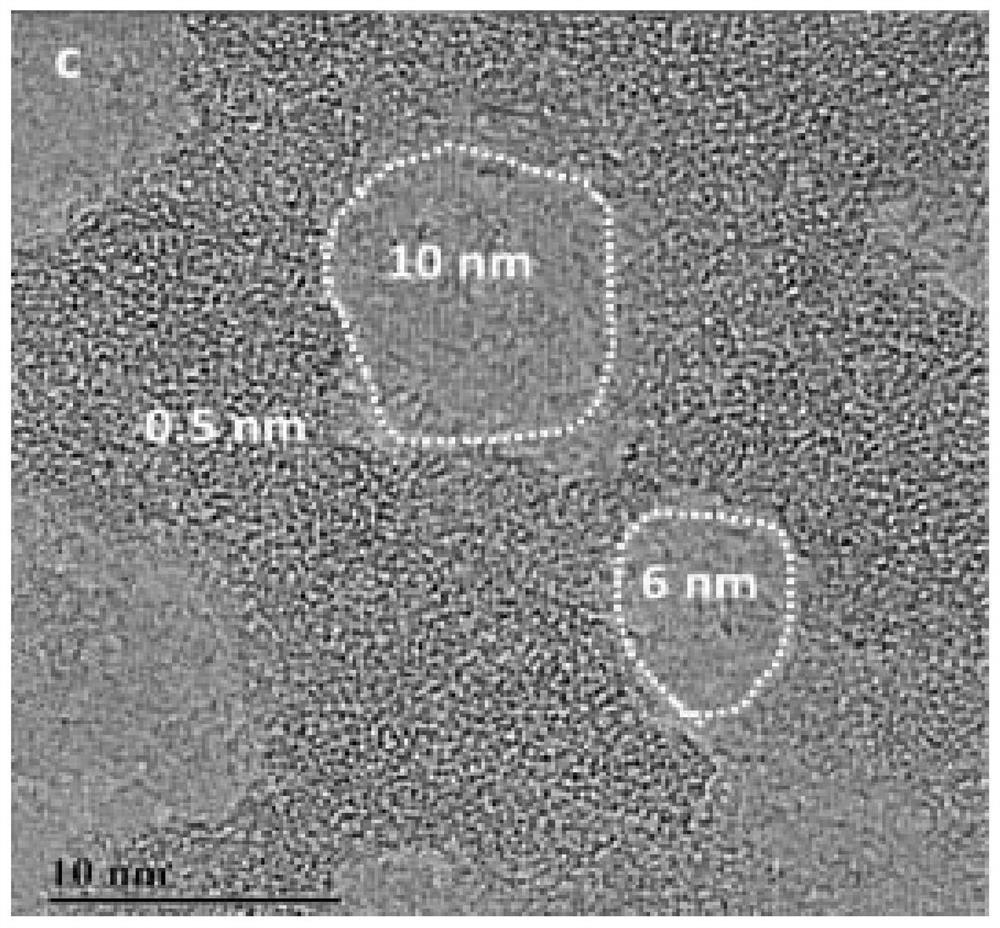

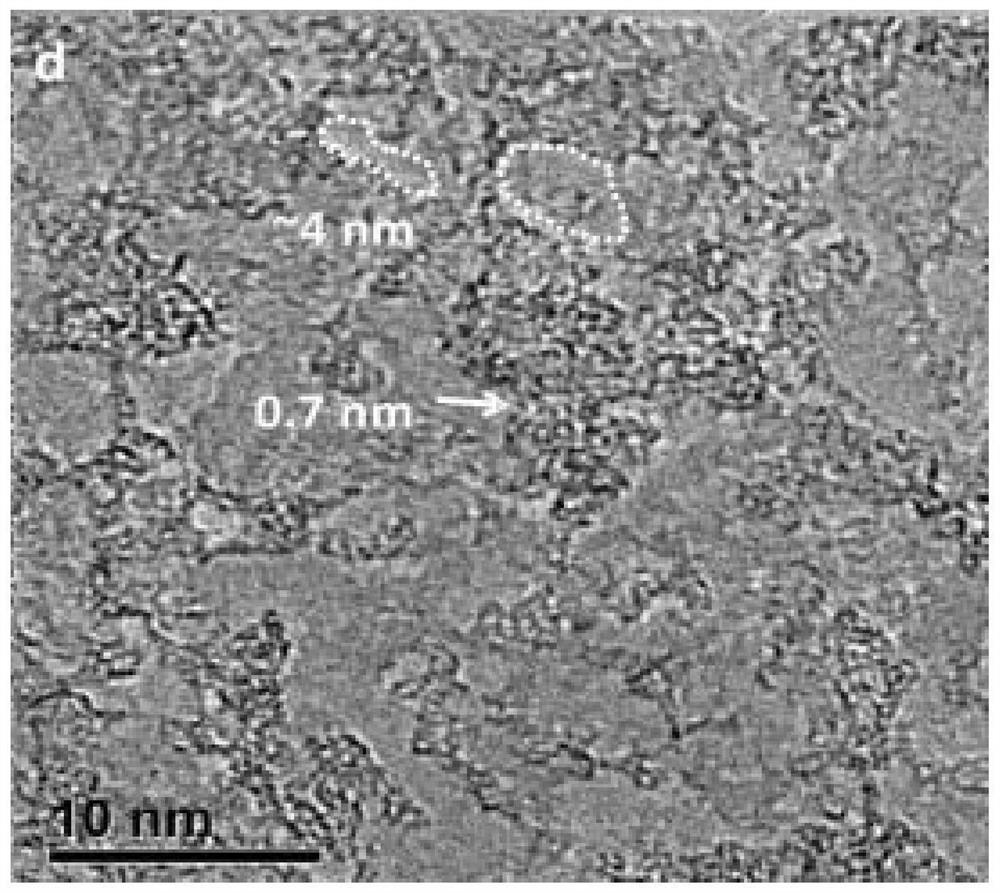

Image

Examples

Embodiment 1

[0041] The preparation of porous graphene / molecular sieve composite film acid catalyst specifically comprises the following steps:

[0042] (1) Preparation of molecular sieve precursor solution: Mix aluminum source, silicon source, tetrapropylammonium hydroxide and deionized water at a molar ratio of 0.5:60:11.5:1500 to form molecular sieve precursor aqueous solution, specifically weigh 0.6g Aluminum isopropoxide, 19g of tetrapropyl ammonium hydroxide and 160g of deionized water are mixed uniformly to obtain a molecular sieve precursor solution;

[0043] (2) Compounding of graphene and molecular sieve: Mix 30 mL of molecular sieve precursor solution with 30 mL of graphene dispersion (2mg / mL) (the content of graphene relative to the molecular sieve precursor is 24wt%), and stir at room temperature for 4h After mixing evenly, stir at 90°C for 24 hours. The precipitated product is centrifuged and washed 3 times with an aqueous solution of ethanol (ethanol: water = 1:1, v / v), and ...

Embodiment 2

[0054] The preparation of graphene / molecular sieve composite porous solid acid catalyst specifically comprises the following steps:

[0055] (1) Preparation of molecular sieve precursor solution: Mix aluminum source, silicon source, tetrapropylammonium hydroxide and deionized water at a molar ratio of 0.6:30:5:500 to form molecular sieve precursor aqueous solution, specifically weigh 0.6g Aluminum isopropoxide, 19g of tetrapropyl ammonium hydroxide and 160g of deionized water are mixed uniformly to obtain a molecular sieve precursor solution;

[0056] (2) Compounding of graphene and molecular sieve: Mix 100 mL of molecular sieve precursor solution with 200 mL of graphene dispersion (2 mg / mL) (the content of graphene relative to the molecular sieve precursor is 18 wt%), and stir at room temperature for 4 h After mixing evenly, stir at 50°C for 48 hours. The precipitated product is centrifuged and washed 6 times with an aqueous solution of ethanol (ethanol: water = 1:1, v / v), an...

Embodiment 3

[0067] The preparation of graphene / molecular sieve composite porous solid acid catalyst specifically comprises the following steps:

[0068] (1) Preparation of molecular sieve precursor solution: Mix aluminum source, silicon source, tetrapropylammonium hydroxide and deionized water in a molar ratio of 1:0.00625:0.25:30 to form molecular sieve precursor aqueous solution, specifically weigh 0.6g Aluminum isopropoxide, 19g of tetrapropyl ammonium hydroxide and 160g of deionized water are mixed uniformly to obtain a molecular sieve precursor solution;

[0069] (2) Compounding of graphene and molecular sieve: Mix 60 mL of molecular sieve precursor solution with 100 mL of graphene dispersion (2mg / mL) (the content of graphene relative to the molecular sieve precursor is 30wt%), and stir at room temperature for 4h After mixing evenly, stir at 120°C for 12 hours. The precipitated product is centrifuged and washed 4 times with an aqueous solution of ethanol (ethanol: water = 1:1, v / v), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com