Molding method for helicopter cockpit door sliding window U-shaped guide rail

A molding method and cockpit technology, applied to household components, household appliances, and other household appliances, to achieve the effects of less processing steps, time saving, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

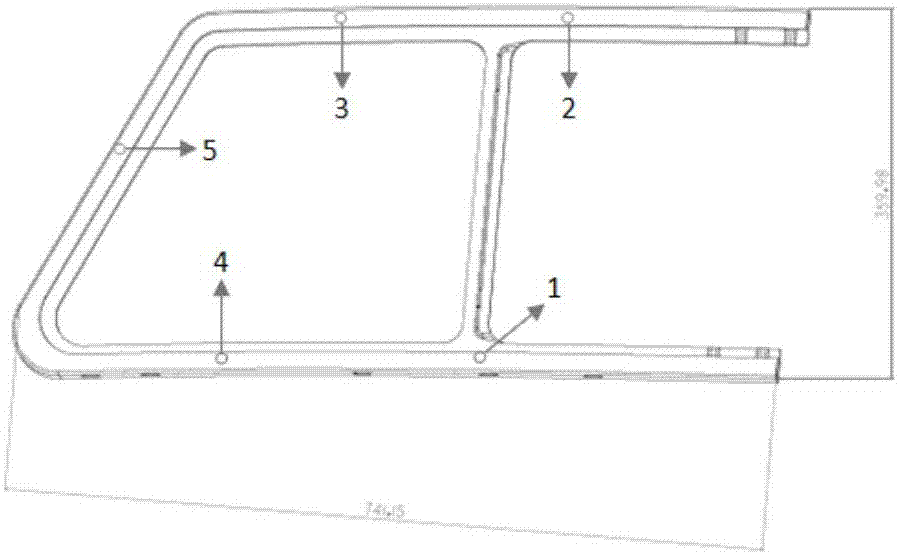

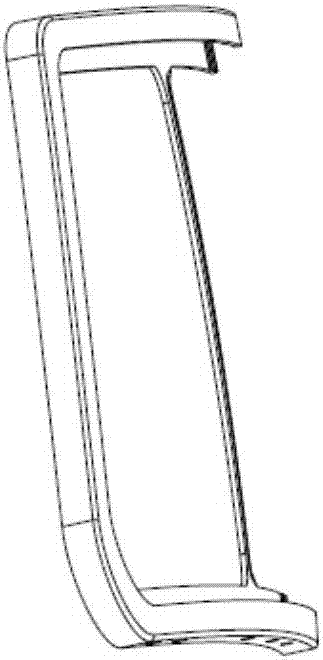

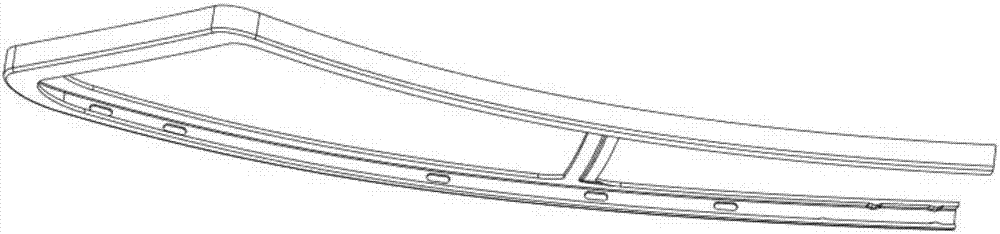

[0039] Taking the formed guide rail with double curvature, variable thickness and U-shaped thin-walled structure characteristics, the guide rail is 741.15mm long, 359.98mm wide, 62.39mm high, 2.2-4.4mm thick, and the guide rail groove width is 13mm as an example.

[0040] The high-precision molding method is injection molding for one-time overall molding. Haitian 1200T injection molding machine is used. The screw diameter is 110mm. The hot runner adopts the 5-point needle valve hot runner method of YUDO company. The resin particle raw material used is The grade produced by the French Akema company is Altuglas V040 plexiglass.

[0041] During molding, the screw temperature is set according to seven stages, which are 190°C, 210°C, 235°C, 240°C, 245°C, 245°C and 240°C; The holding pressure is 55MPa, the first-order holding time is 20s, the second-order holding time is 30s, and the cooling time is 20s; The waiting time until the opening of the fifth glue point is 0s, 2.5s, 2.5s, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com