A kind of high-performance fiber concrete of C110 strength grade and its preparation method

A technology of high-performance fibers and strength grades, which is applied in the fields of high-strength, high-performance fiber concrete and its preparation, high toughness and high durability concrete, and can solve problems such as poor durability, high brittleness, and easy cracking, and improve mechanical properties , Improve the effect of crack resistance and strong grip

Active Publication Date: 2019-10-01

XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The object of the present invention is to provide a kind of high-performance fiber concrete of C110 intensity level and preparation method thereof, the present invention uses cellulose fiber, rice husk ash, modified carbon nanotube, cement, fly ash, river sand, crushed stone for the first time , chemical admixtures (including water reducer, activator, defoamer), and water prepared a fiber high-performance concrete with high volume stability, high toughness, high durability, and ultra-high strength C110 strength level, overcoming It overcomes the shortcomings of ordinary concrete, such as high brittleness, easy cracking, and poor durability.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Login to View More

Abstract

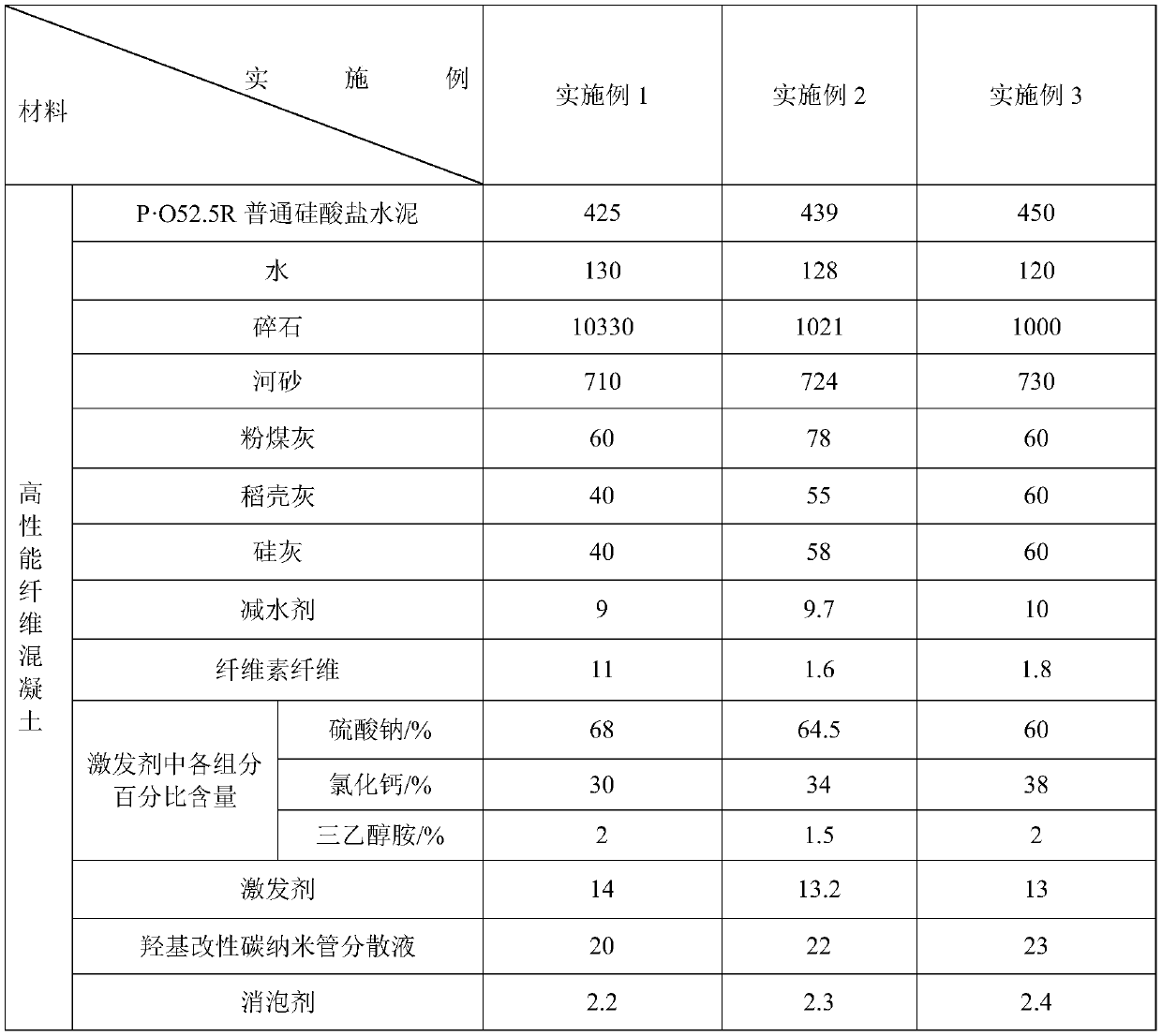

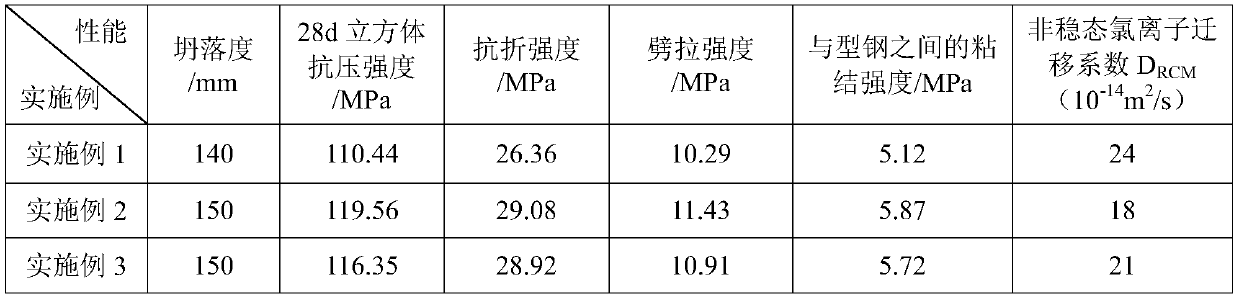

The invention discloses a high-performance fiber concrete of C110 strength grade and a preparation method thereof. The mass parts of the concrete are as follows: 425-450 parts of cement, 120-130 parts of water, 710-730 parts of river sand, and 1000 parts of gravel ‑1030 parts, 60‑90 parts of fly ash, 40‑60 parts of rice husk ash, 40‑60 parts of silica fume, 9‑10 parts of water reducing agent, 13‑14 parts of activator, 1.1‑1.8 parts of cellulose fiber, Hydroxyl-modified carbon nanotube dispersion liquid 20-23 parts, defoamer 2.2-2.4 parts. The prepared concrete has high toughness and excellent durability, and has high bonding strength with section steel. Used in steel-concrete composite structures, it can effectively exert the synergistic performance between steel and concrete, make up for the poor bonding performance of steel and concrete, and the inability to give full play to their respective mechanical properties.

Description

technical field The invention belongs to the field of new building materials, and is a high-strength, high-toughness and high-durability concrete mixed with rice husk ash, cellulose fibers and modified carbon nanotubes, in particular to a high-toughness C110 high-strength concrete Performance fiber concrete and method for its preparation. Background technique Ordinary concrete and cement-based materials have low tensile strength and poor toughness, and a large number of micro-cracks will occur during hardening or under external loads, which seriously affect the durability of concrete or cement-based composite structures and reduce the service life of structures. In order to overcome the brittleness of ordinary concrete and high-performance concrete, asbestos fibers, steel fibers, carbon fibers, polyvinyl alcohol fibers, polypropylene fibers, and basalt fibers with toughening effects are used in concrete. The use of a large number of fibers is easy to form agglomerates in co...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B28/04

Inventor 郑山锁董方园张艺欣郑捷周炎董立国郑淏宋明辰陈家悦牛丽华秦卿阮升

Owner XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com